3D Scanning and Printing Group Assignment

This section describes the design rules for the Ultimaker 2 Extended+ printer in the lab.

The test piece was taken from this link.

The printing parameters are as follows:

- Layer Height: 0.15 mm

- Wall Thickness: 0.7 mm

- Infill Density: 18%

- Material: PLA

- Print Speed: 60 mm/s

- Travel Speed: 150 mm/s

- Build plate adhesion type: skirt

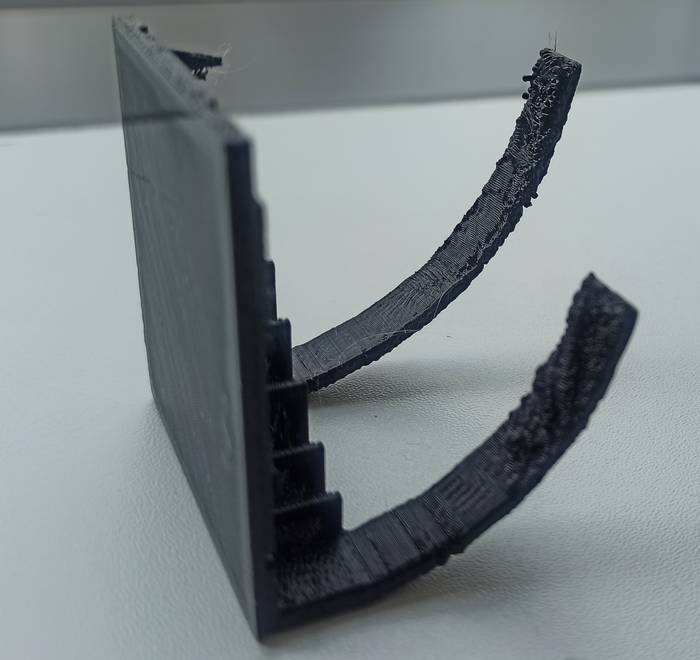

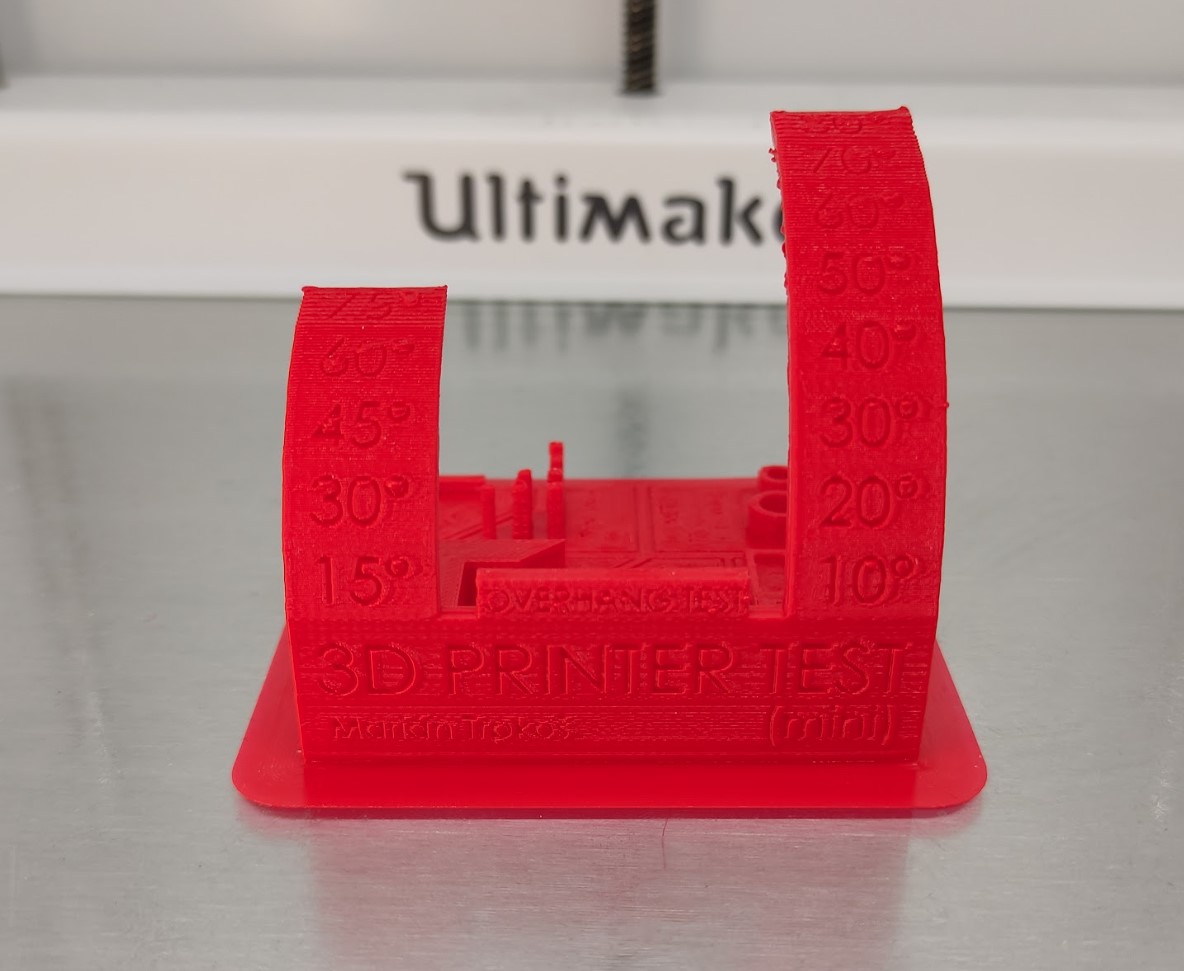

The result of the printout was as follows

On the back of the piece you can see some strings, that means that it is necessary to increase a little the retraction to correct it.

In addition, the angle of inclination where it starts to leak a little bit of filament is approximately 45 degrees.

In general terms the printing parameters are working quite well but can be improved depending on the shape and functionality of the part to be printed.

Test piece¶

The recommendation for every fabrication technique is making a testing piece beforehand, in this case we want to know the “design rules for our printer”.

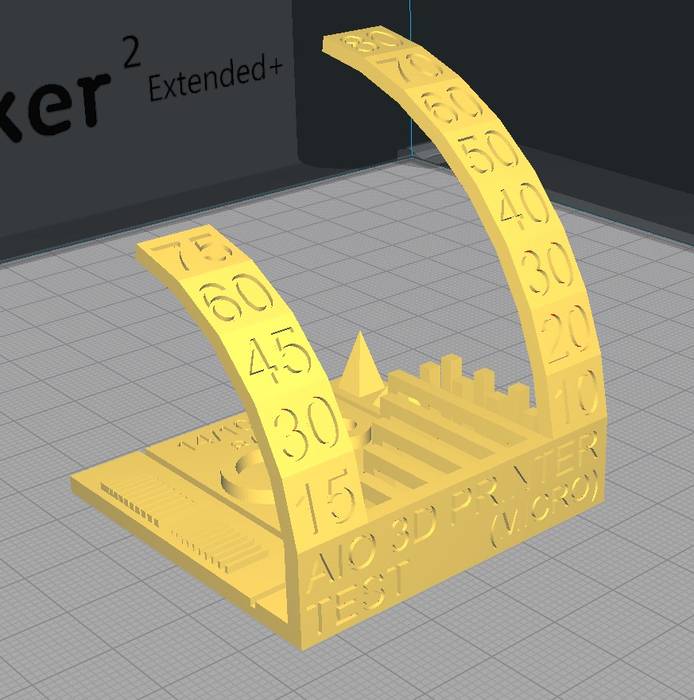

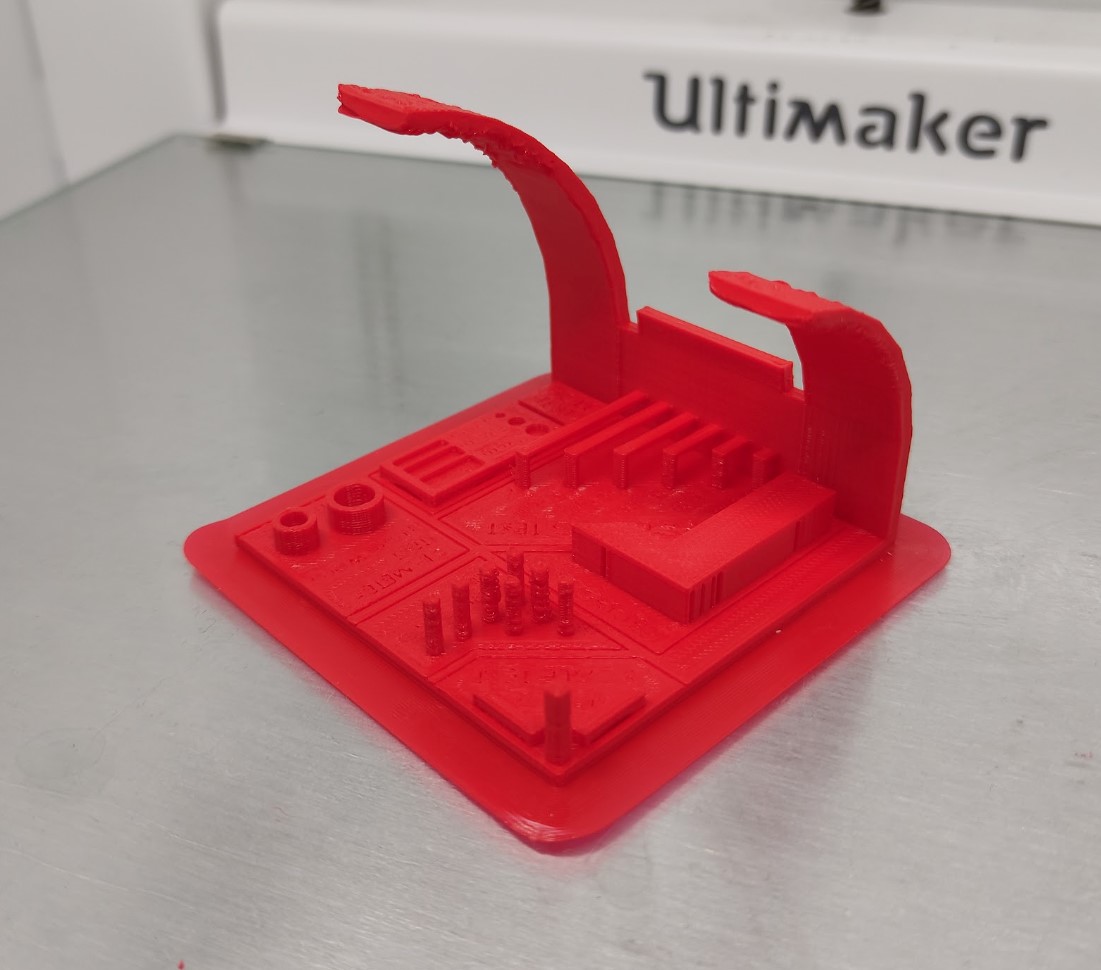

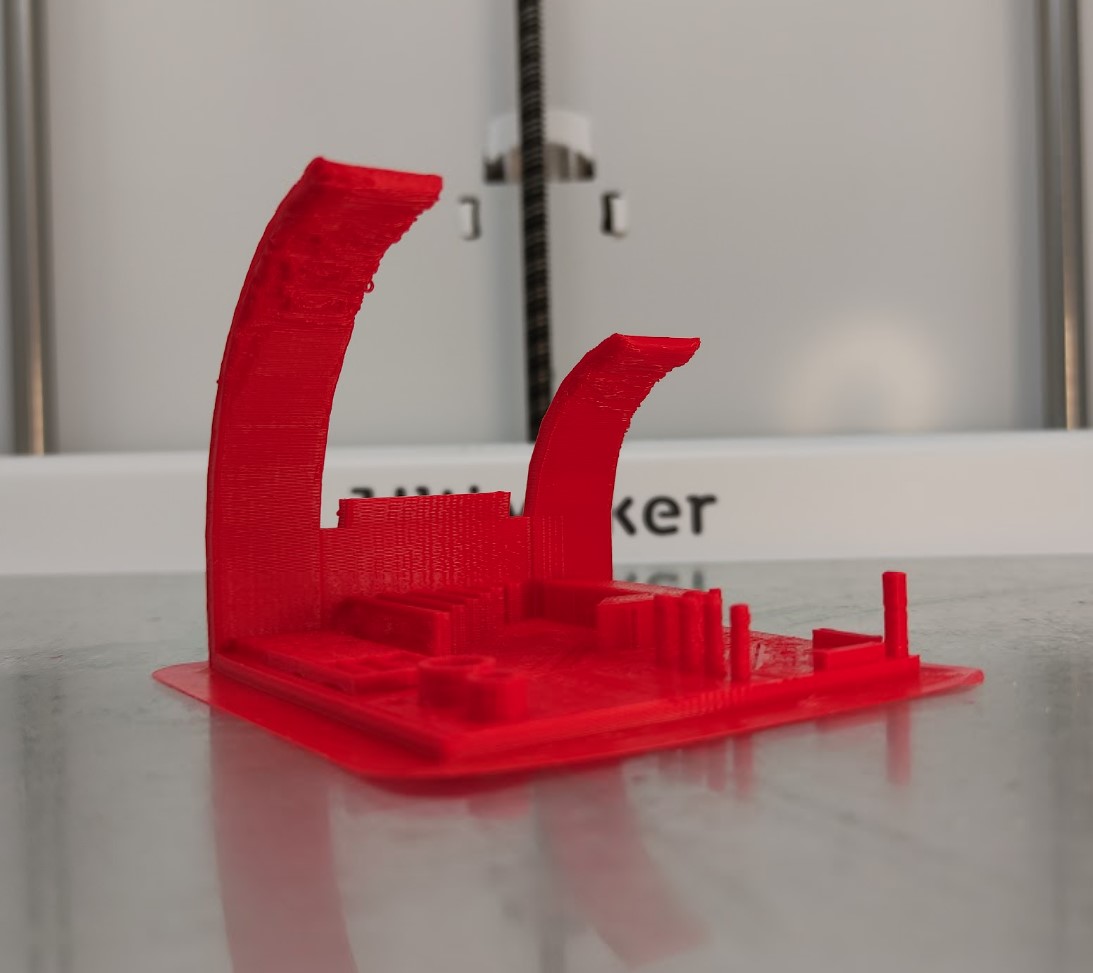

For this task I have used the All In One 3D printer test model by Marián Trpkoš that includes Overhang, Brigding, Hole and Diameter tests:

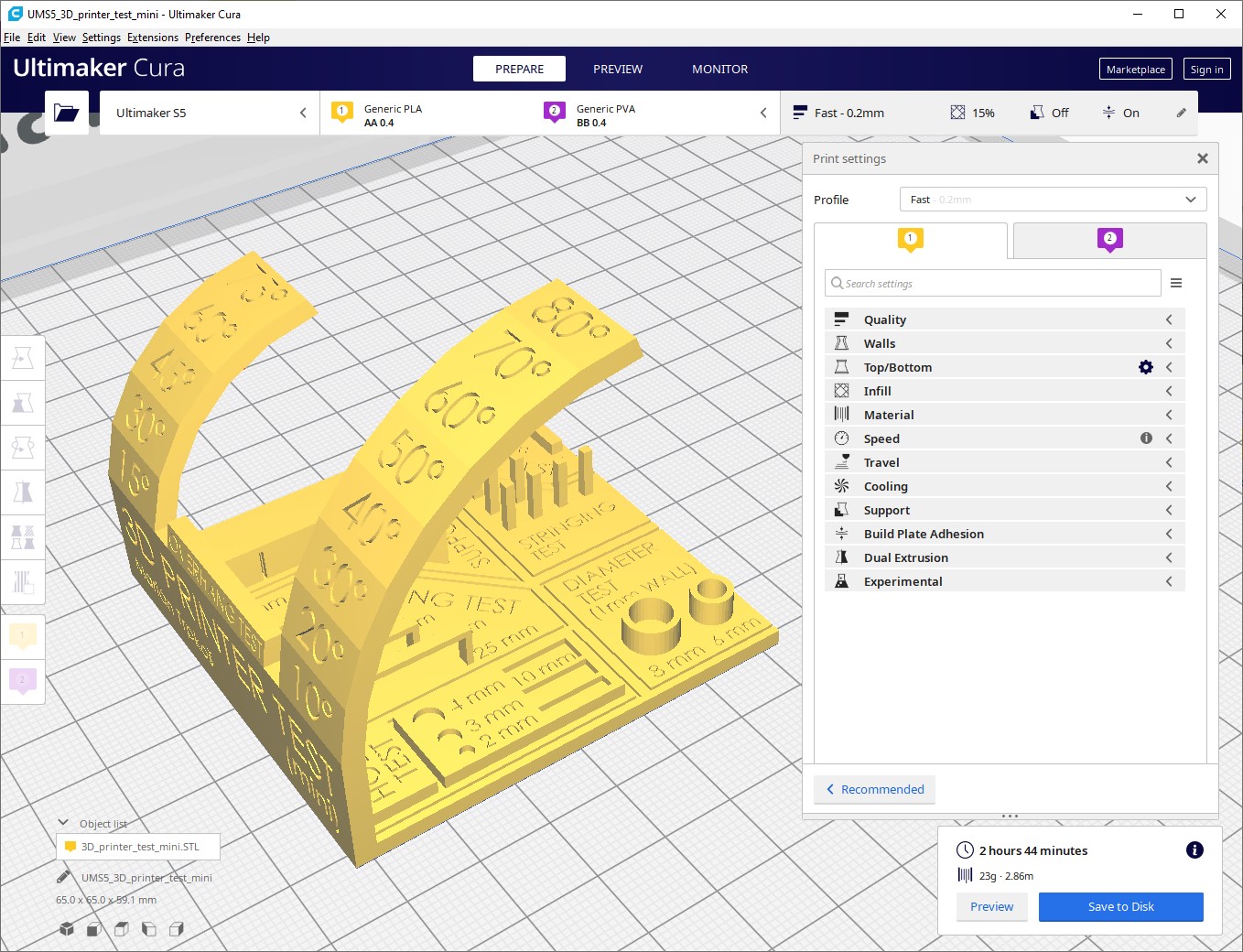

I used the default parameters of the Fast printing profile:

- Supports = Disabled

- Layer height = 0.2mm

- Build plate adhesion = Brim

- Infill = 15% triangles.

- Infill speed = 70mm/s

- Wall speed = 55mm/s

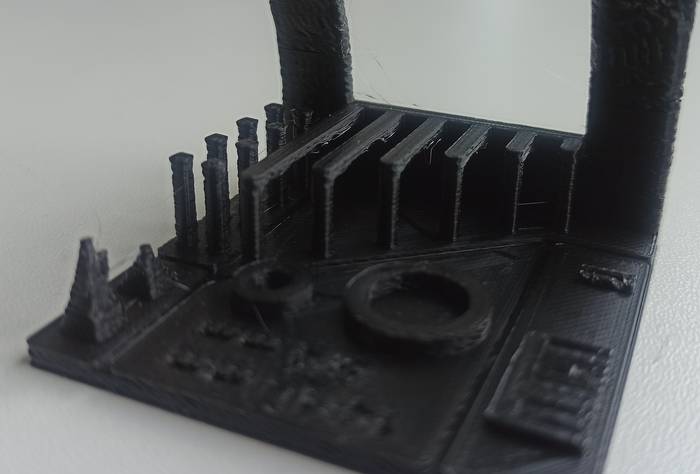

Resulting piece:

The 3D printer I used during this assignment was the Ultimaker S5, with a AA0.4 (0.4mm) nozzle and 2.85mm generic PLA filament:

Conclusions:

From this piece we can take note of various aspects for both model design and slicer parameters; some of them are known at first glance, others have to be measured. The most important that I can mention are:

-

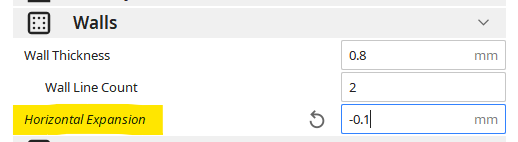

Printing tolerance = 0.25mm, it means that the printed walls of the piece are 0.25mm wider than the ones in the 3D model, . It can be fixed either editing the crucial measurements in the 3D model or simply using a negative Horizontal expansion in Cura:

-

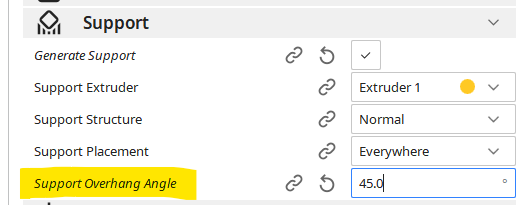

The minimun angle of overhang for which add support ≈ 45°:

-

The longest bridge that can be printed without starting to collapse = 20mm.

-

It was remarkable that horizontal text at this size doesn’t work that well 😅, it wasn’t readable.

-

Sharp vertical positive edges are practically impossible to get, the printer in an attempt to complete the form, will add extra material. A recommendation for it would be to fillet the edges of the 3D model to at least the radius of the nozzle:

In general terms, the parameters of the printing profile used work fairly well if we want to print a first test/prototype/draft.