10. Input devices¶

General Info¶

Nueval¶

- https://nueval.fabacademy.org/#/login

- With students with 2 or more assignments marked Complete at local eval level, you CAN request a Global Evaluation for them now.

- Global Evaluation has started.

schedule¶

- Apr 07: input devices

- Apr 14: molding and cansting

- Apr 21: output devices

- Apr 28: networking and communications

- (May 1: final presentations sign-up)

- May 05: interface and application programming

- May 12: wildcard week

- May 19: applications and implications

- May 26: invention, intellectual property, and income

-

Jun 02: project development

-

final presentations

- sign-ups open May 1

- Wed Jun 09

- Fri Jun 11

- Mon Jun 14

- Wed Jun 16

- (Fri Jun 18)

- June 21: local to global eval cutoff

- July 05: global eval to student cutoff

- July 12: global eval to FAB16 graduation cutoff

- Aug 9-13: FAB16

- Dec 01: post-FAB16 cutoff for this cycle

final project pages¶

- Final project requirements

- Project Development | video

- tracking your progress

- what tasks have been completed, and what tasks remain?

- what’s working? what’s not?

- what will happen when?

- Project management

- documentation during development

- demand- vs supply-side time management

- spiral development,

modling and casting¶

- ref. last year

- MDX-15

- work area: 152.4mm × 101.6mm × 60.5mm

- Machinable wax

- size: 152mm x 92mm x 39mm (real size is smaller)

- Endmill

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

- Size: 1/8”=3.175mm

- OverAll Length: 2-1/4”(2.25”) =57.15mm

- 0.0625” DIA 2FL SE AlTiN 1/16

- Size: 1/16” =1.5875mm

- OverAll Length: 1-1/2”(1.5”) =38.1mm

- 0.1250” DIA 4FL SE LONG AlTiN 1/8

- Design to think…

- XY size: real wax size

- Final Part size < wax size - wax_wallx2 - mold_wallx2

- distance between bumps凸 & dents凹: tool size > 1.58mm(1/16”) > 0.79mm(1/32”)

- Z depth: 1.5 in mill > 38.1 - 10mm?_collet

- Registration Key, Registration post

- XY size: real wax size

-

Process

- 3D modeling

- Fusion360

- Tool Path

- Modela Player4 (Windows)

- Virtual Modela (Windows)

- Rough cut (1/8”)

- Finish cut(1/16”)

- 3D modeling

-

3D modeling

- sample

- design final part (positive)

- design molds to make final part (negative)

- design wax to make molds (positive)

- make

- pour liquid silicone rubber into wax to cast molds (negative)

- pour liquid resin into molds to cast final part (positive)

Assignment¶

Individual assignment:¶

Note

measure something: add a sensor to a microcontroller board that you have designed and read it

Group assignment:¶

Note

probe an input device’s analog levels and digital signals

TODO: Individual assignment¶

add a sensor to a microcontroller board that you have designed

-

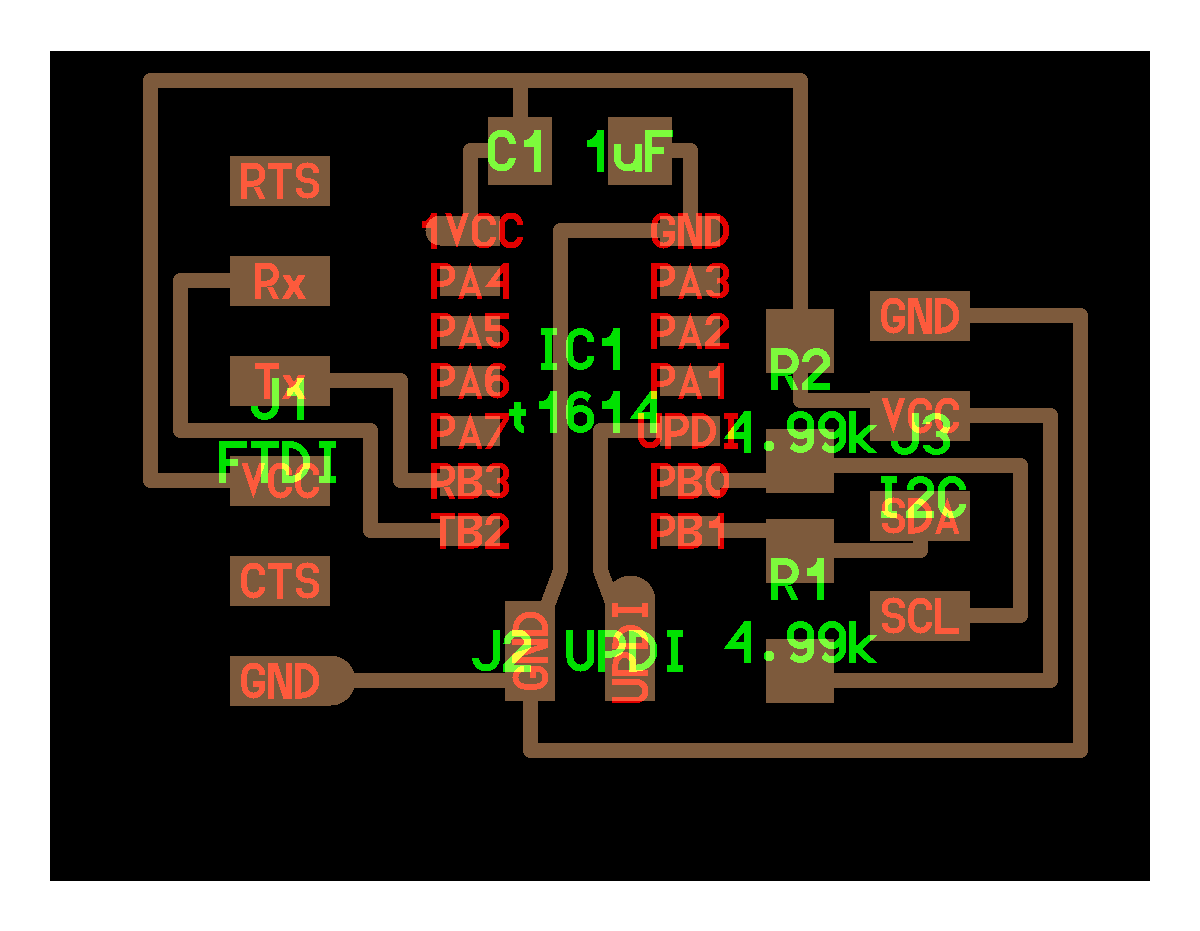

AVR 1-series

- 412

- 1614

- 3216

-

pinout

Tips

1 2 3 4 | |

- network port

- I2C

- SDA

- SCL

- pull up 4.99k each

- ref. wiki

- I2C

and read it

- serial monitor

- pyserial

- processing

- chrome extension

- test and samples

- Read input value on Attiny1614 over serial and display it

- Serial monitor

- Serial plotter

- Python(Tkinter)

- Processing

- Browser(p5.js)

- Serial plotter on Attiny3216 breakout board

- Read input value on Attiny1614 over serial and display it

Group assignment:¶

probe an input device’s analog levels and digital signals

- oscilloscope

- probe analog signal before IC

- probe digital signal after IC

Assessment¶

- Can I use a breadboard and/or jump wires to interface my input device(s)

- Answer: No. You can’t use a breadboard. If you use wires, they must be soldered or connected with connectors.

Last update: April 13, 2021