This is the seventeen week assignment for the Fab Academy 2018.

.Applications and implications

The goal of this week assignment is to answer the questions set for this assignment

What will it do?

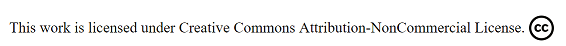

Throughout my 3 years working in 3D printing, I noticed the amount of wasted filament after each print. My machine, called Fab Extruder, will recycle waste material (PLA, ABS,etc). The machine will have a funnel where the filament would go through a spiral lead screw and would push the material to a heated nozzle. I made two interchangeable nozzles with two different diameters, 1.75mm and 2.85mm. We will have a new filament at the end to be used with future prints.

Who's done it beforehand?

Upon further research, there were a few projects of filament recycling extruders. Three caught my attention being commercial and similar to what I originally had in mind minus few improvements. I wanted to build a similar machine with a lower cost to benefit the fab lab community around the world, where anyone from any Fab lab can build one using material and processes available at hand.

A student from Fab Academy 2016 done a similar one, but for some reason, the filament did not come out of the machine. My goal is to have a successful recycled filament.

What materials and components will be required? And where will they come from?

All below components will have hyperlinks to their sources

Components:

ATMEGA Processor – will have additional boards that I haven't built yet

Material

All the materials were available at the lab except for the lead screw because it was difficult to build one and was purchased from a local hardware store.

PLA _for the extensions, holder, and case.

Acrylic _ for the case.

Wood _ for the base

Metal pipe.

Copper _ for the nozzle

Metal screws and nuts.

What parts and systems will be made?

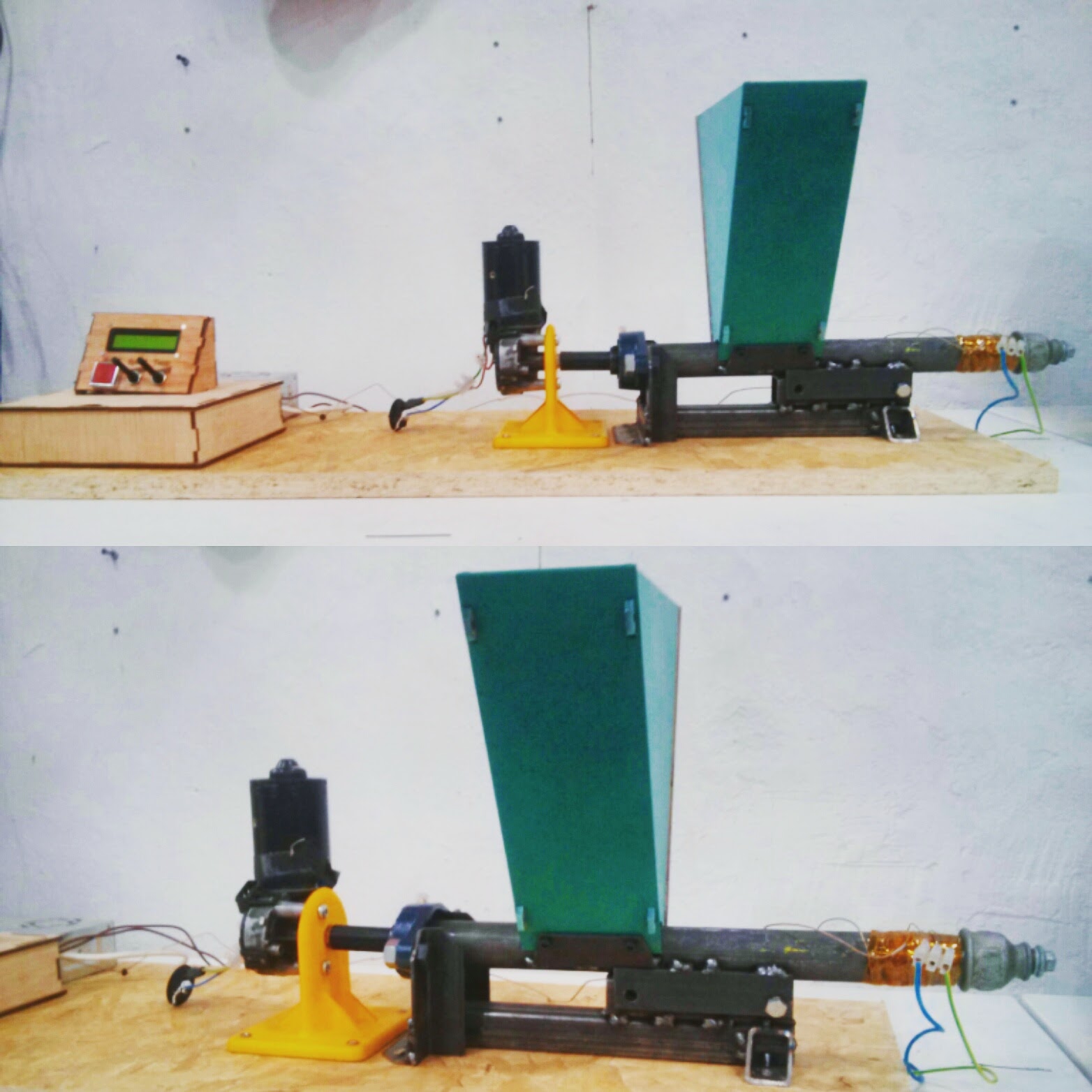

The entire structure, PCB, and the ATMEGA board will be made in the fablab. However, the DC motor, touch screen and the components were purchased.

What processes will be used?

.2D and 3D designs

.Laser cutting

.3D printing

.CNC Milling

.Lathe machine

.Electronic design and production

.Input and output devices

.Embedded programming

.Interface and application programming

(All metal parts will be manufactured manually using the lathe machine)

What tasks need to be completed?

I am working on the design at the moment, 2D and 3D. I am also designing the PCB boards which are still in process.

What questions need to be answered?

The most important thing is whether anyone from the fablab community will be able to build the same machine with a low cost. Whether the machine will be easy to assemble. Will the machine be useful to me and the lab, and finally will I be able to use the recycled filament with new prints.

What is the schedule?

I used my time during some assignments (such as input & output devices assignment) to have a result that is related to the final project. I would like to have the machine up and running by June 10th, 2018. I will make sure the system is functioning properly. I will have extra 5 days to document the entire process, film a tutorial, and present my project. I would like to be ready for the presentation by June 15th.

The cost of the project

| Component | Name | Cost |

|---|---|---|

|

DC motor | $14.99 |

|

Coupler | $6.56 |

|

Ktype thermocouple | $10.99 |

|

Lead Screw | $25 |

|

Touch screen | $24.98 |

|

Heater | $19.73 |

| Solid State Relay | $4.69 |