Electronics Production

This week was focussed to become familiarised with Electronic Production specifically PCB production.

Milling Board

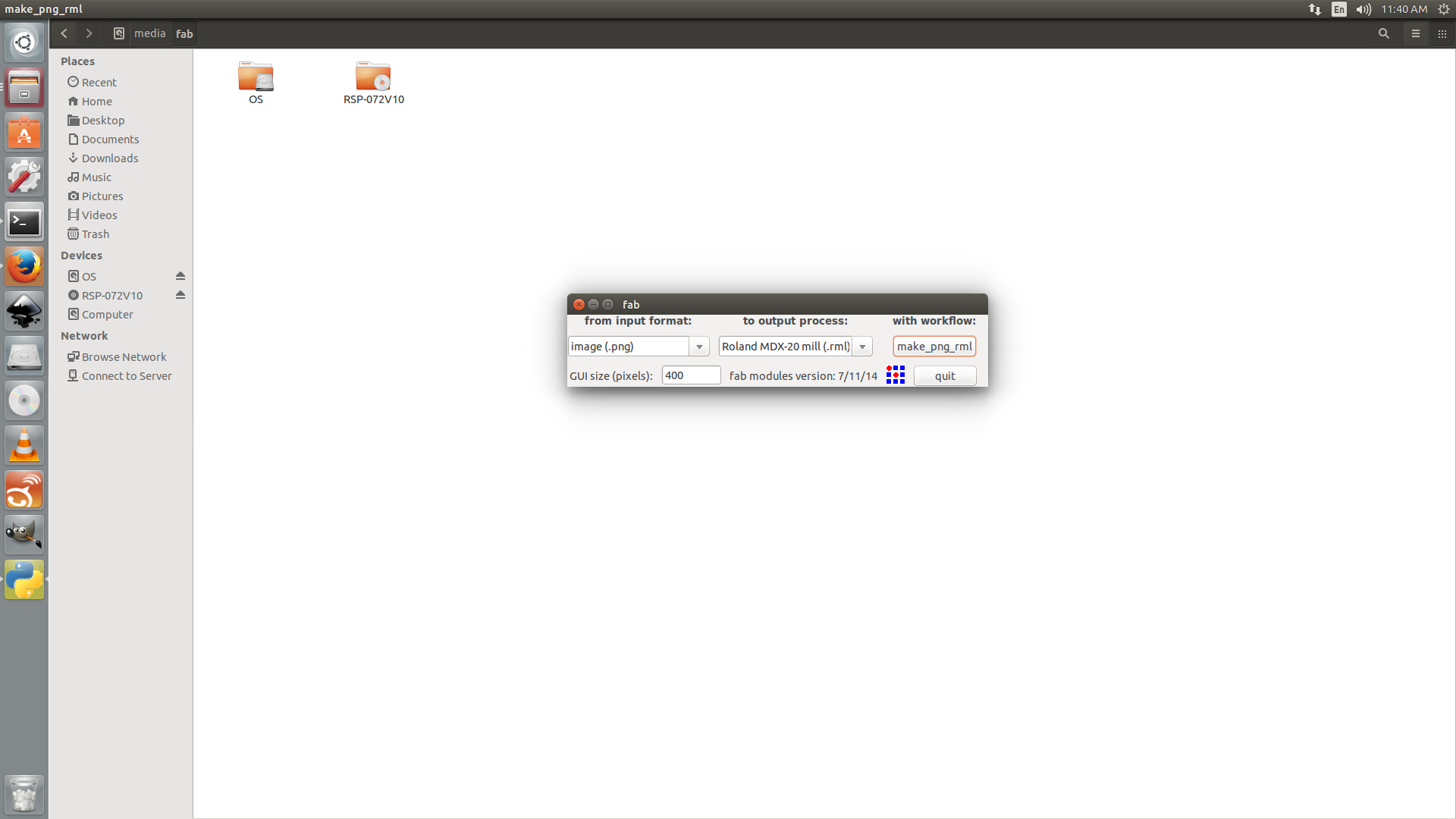

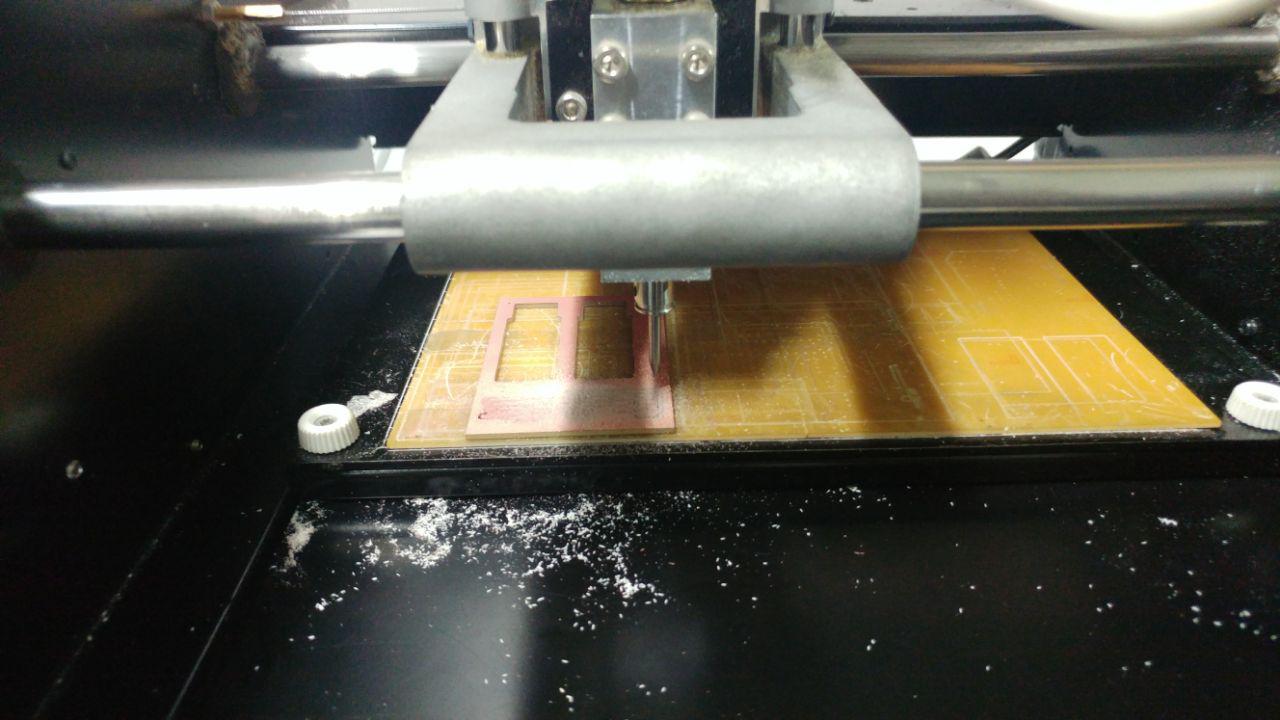

Milling Machine

we have a Roland SRM machine which is our primary electronics milling machine.

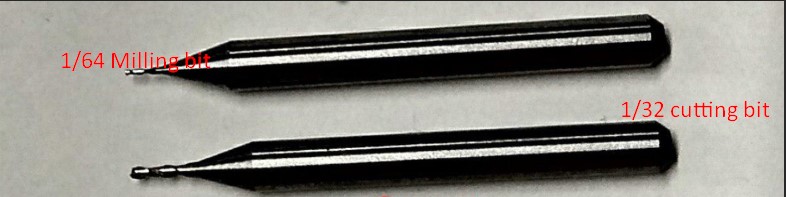

We are mainly using two kinds of bits a 1/64 inch and 1/32 inch. The first one is used for tracing purposes and the second one is used for cutting purposes.These numbers indicate the diameters of the bits.

.

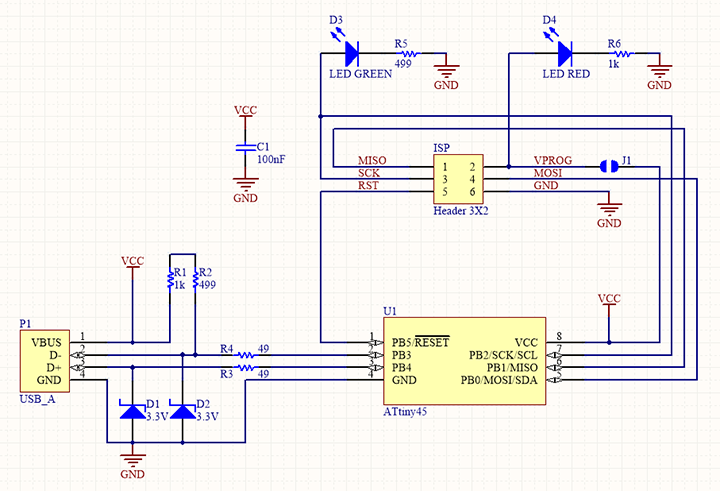

ISP PCB Design

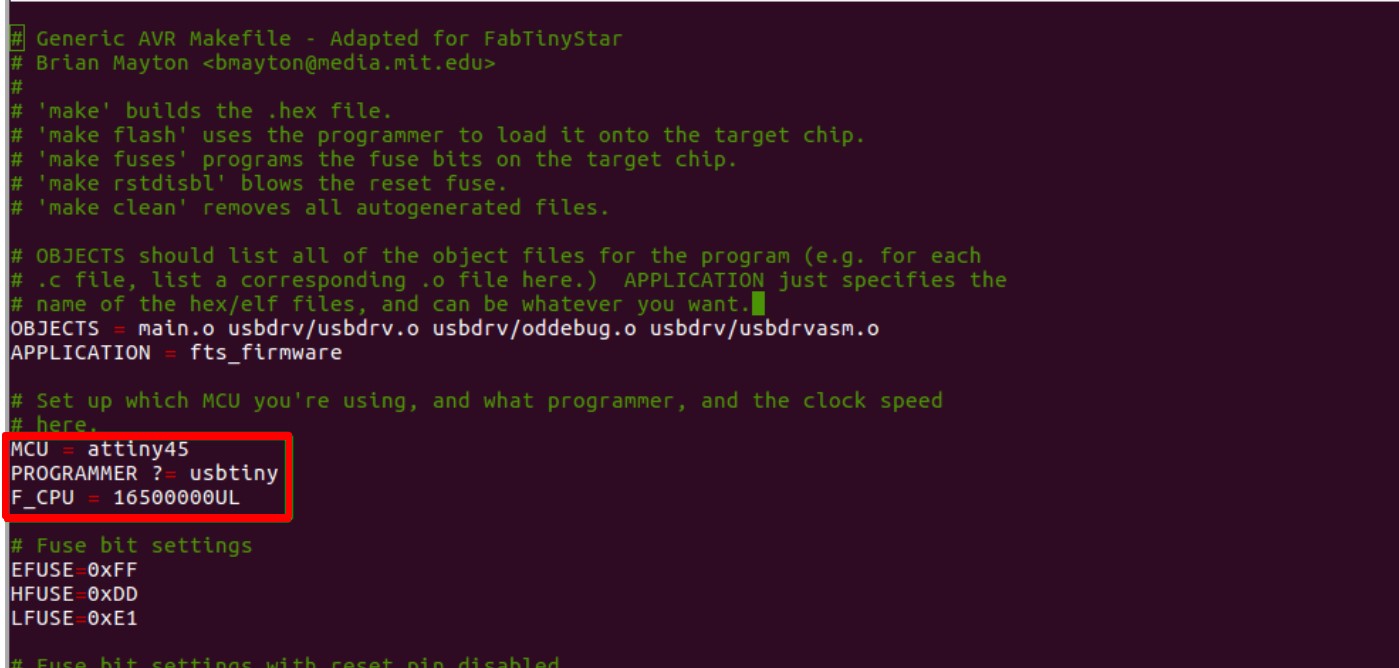

Goal of this week was to build a Attiny programmer which can be used to program other boards in the rest of the course. I used earlier ISP schematics and board from academy page to mill the device.

ISP schematics

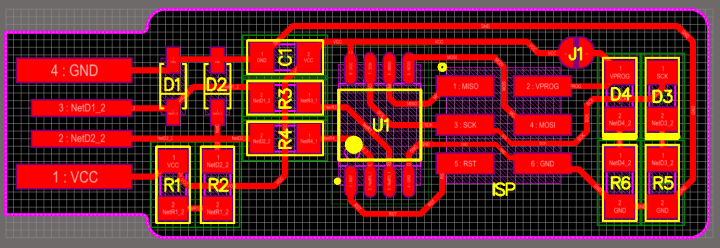

ISP Board

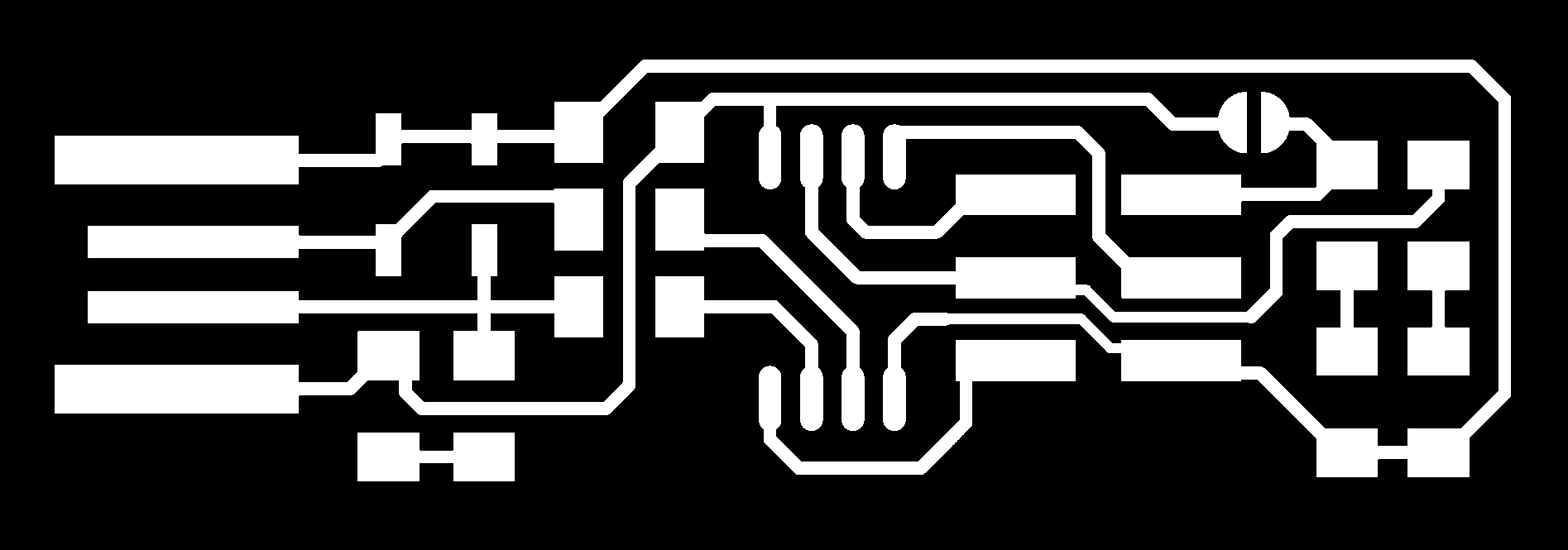

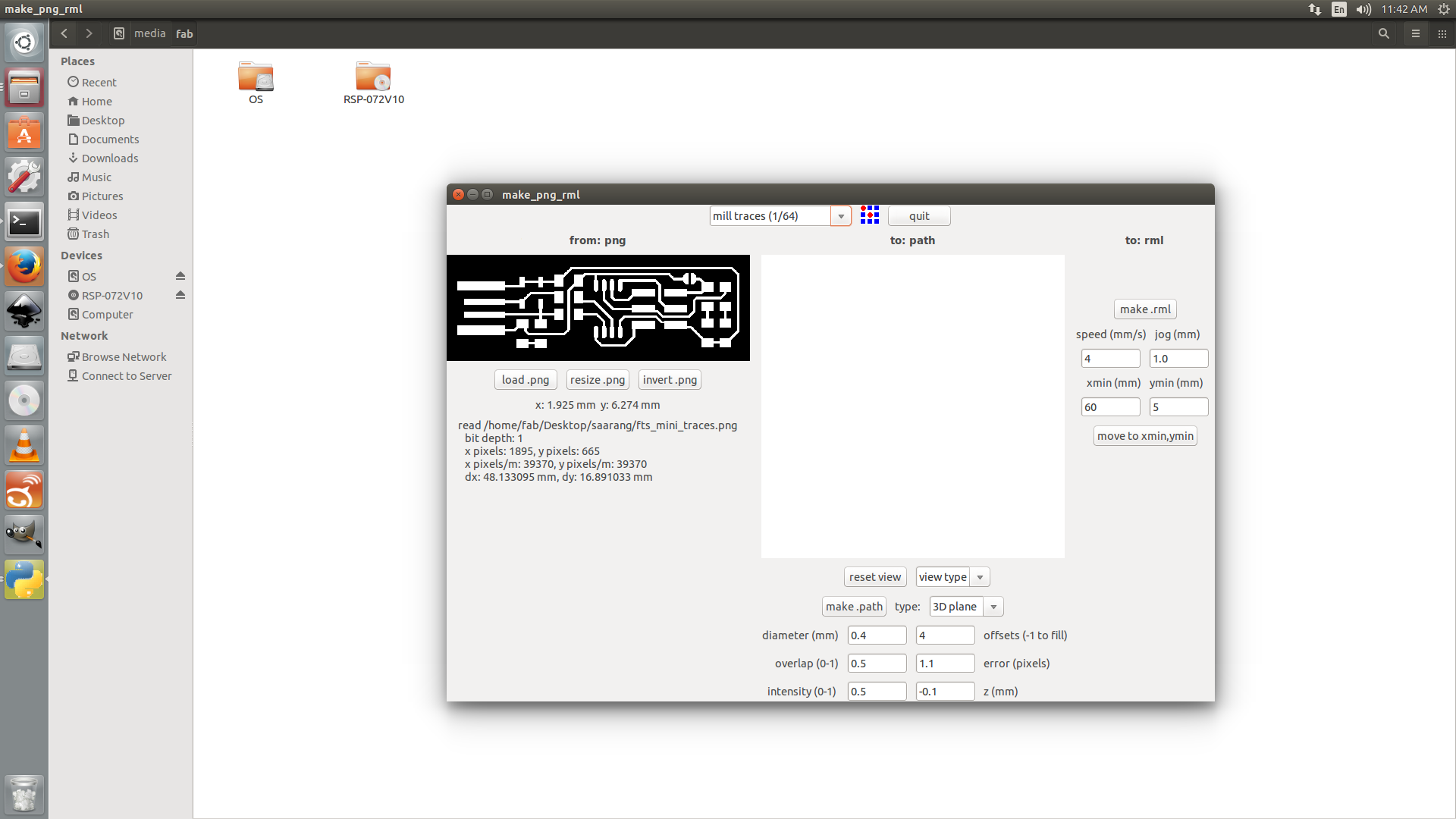

Trace Image

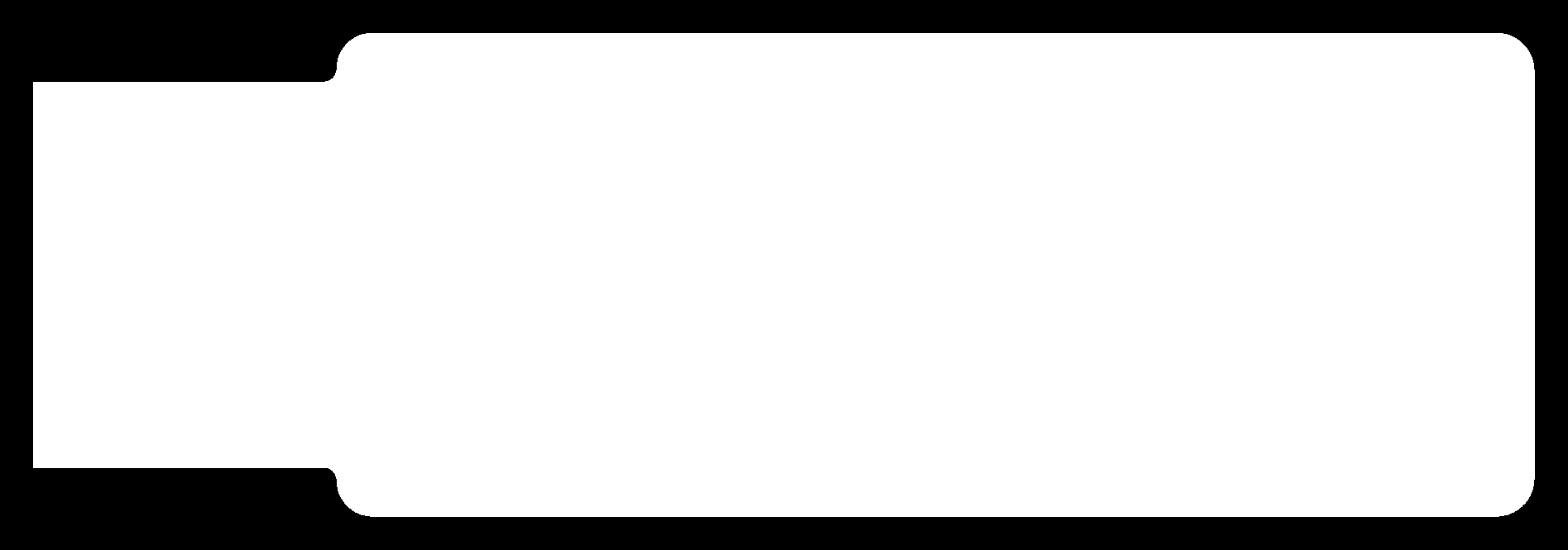

Cut Image

I initially loaded trace image into the program and observed the path.I used 1/64 bit to mill the board.

After that i used 1/32 bit to cut the circuit.

We used 1/64 bit to mill the trace and used 1/32 to obtain the cut image.

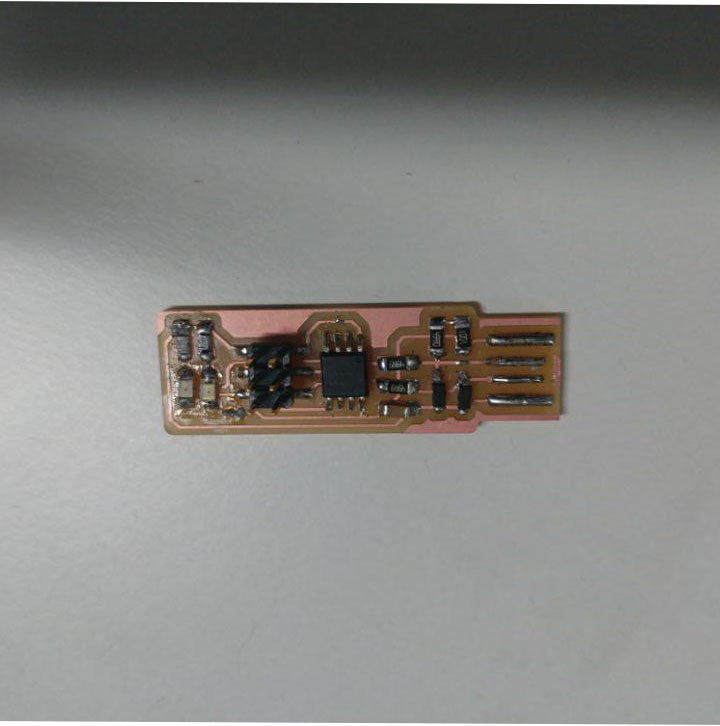

Soldereing Board

Next part was to soldering board.I had experience in soldering board but it took a lot of time to get it correct this time.My friends in lab helped me to trouble shoot the problem

I used following components to complete the soldering

.

.

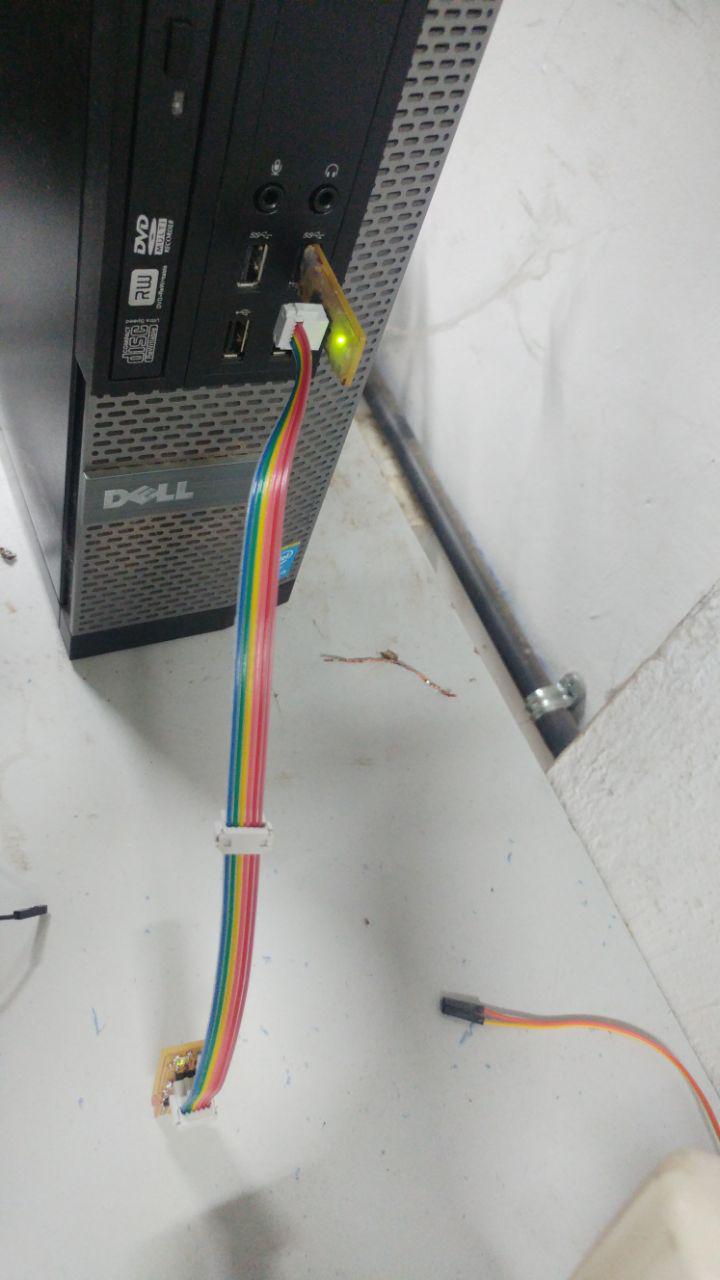

Flashing the board

we need to flash the device to make it work.For that we downloaded firmware from academy page. After that enter these command in terminal to download avr-gcc tool chain

sudo apt-get install avrdude gcc-avr avr-libc make

After installation unzip the downloaded folder and makefile in terminal.

Now use the following commands

make

sudo make flashand

sudo make fuseto burn the chip.

Problems

- After the initial checking when we were using avrdude prompt i found flashing was failed. Connection check revealed that my diode was connected in opposite polarity.

- Board also has shorts in the attiny circuit.After correcting these problem circuit worked

Group Project

to characterize the specifications of our PCB production process.We mainly used 2 bits for our process a 1/32 and a 1/64. We checked the minimum resolution that each of these bits could process

Using 1/64 bits

Using 1/32