Computer Controlled Cutting

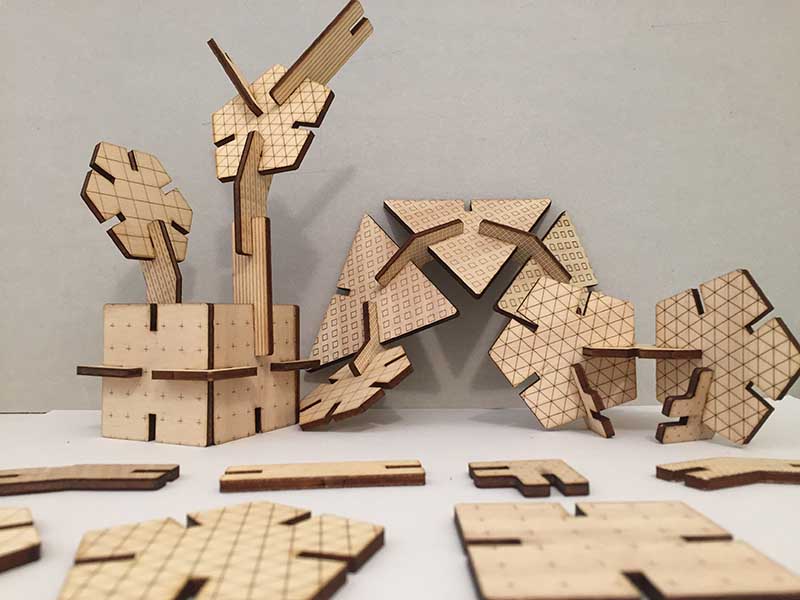

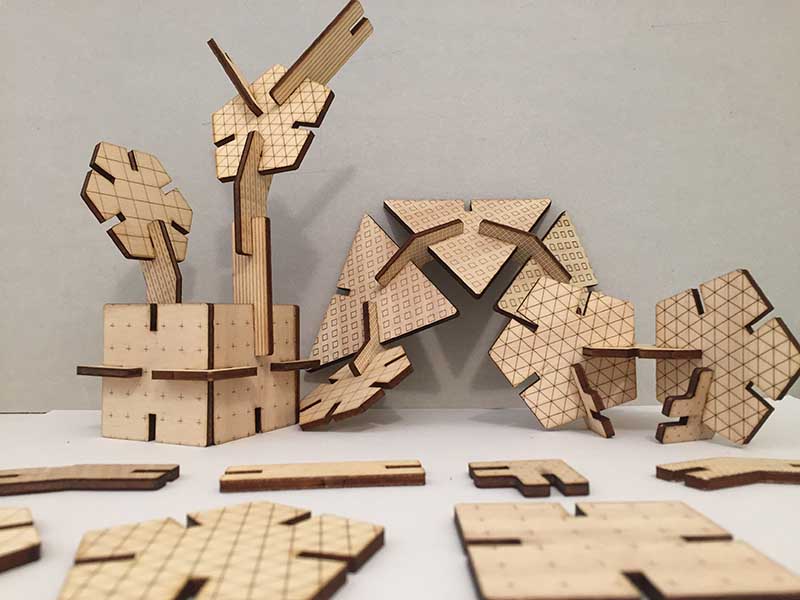

Press and fit game

|

LEVEL: | |

|---|---|---|

| SKILLS: | ||

| TIME: | ||

| MACHINE: | ||

| SOFTWARE: | FUSION360 |

| TOOLS. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BOM: | |

|---|---|

| component name | link |

| component | link |

| component | link |

| component | link |

| component | link |

| component | link |

| component | link |

| component | link |

| component | link |

1. SECTION 1: 3D model with Fusion 360

1.1 Download and install software

Intro about fusion 360 (TO DO):

1.1 Model the puzzle part

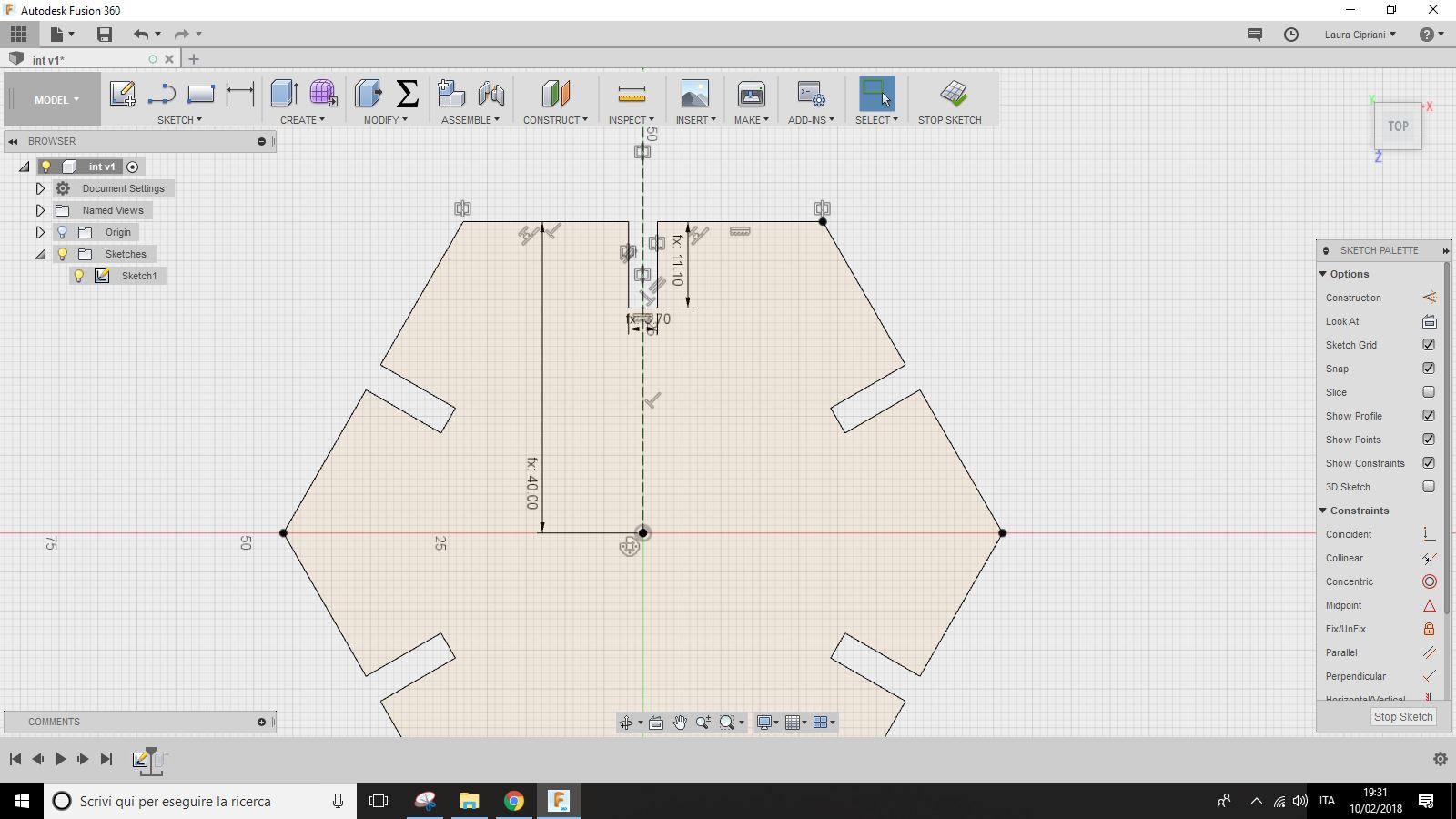

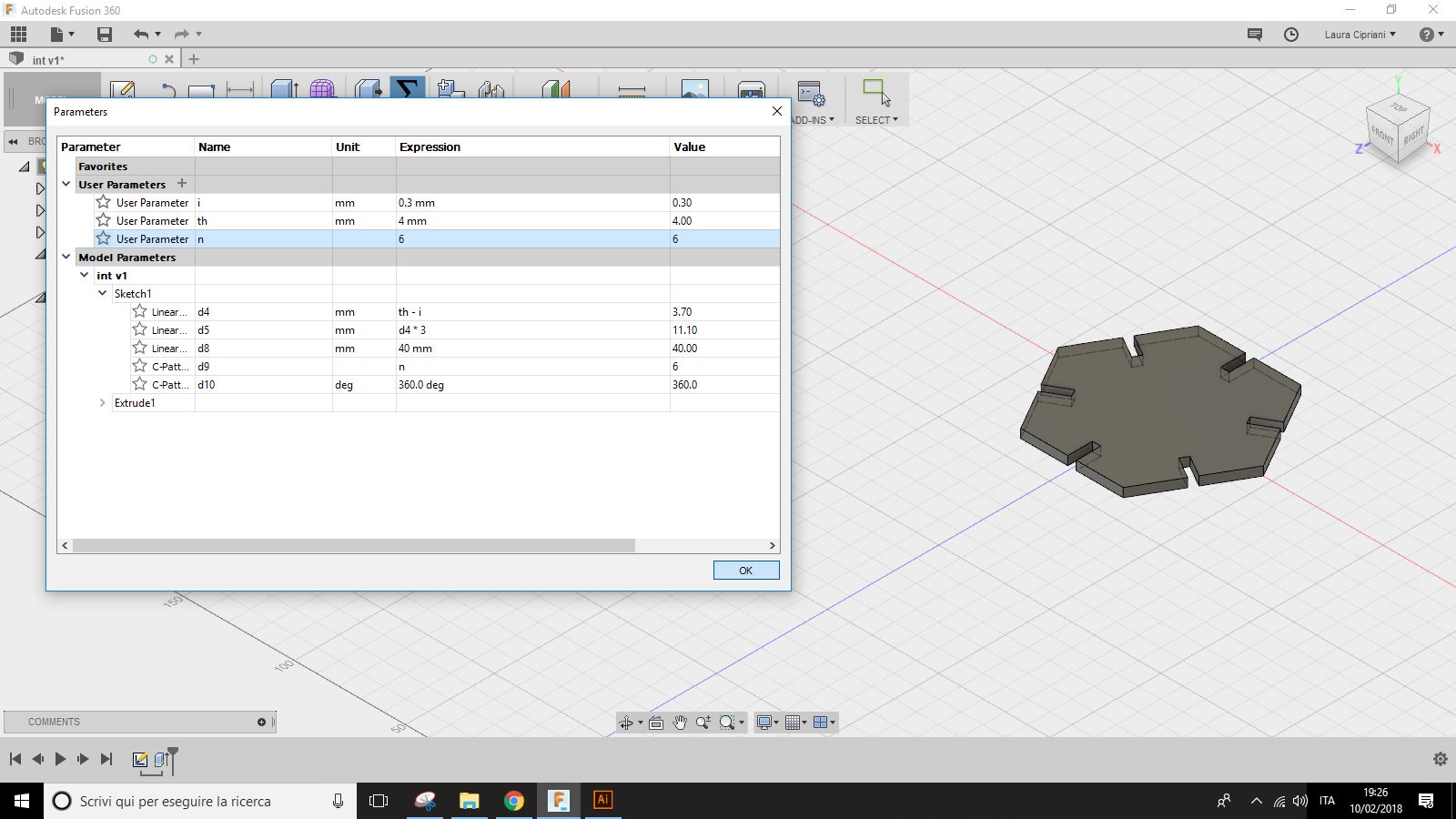

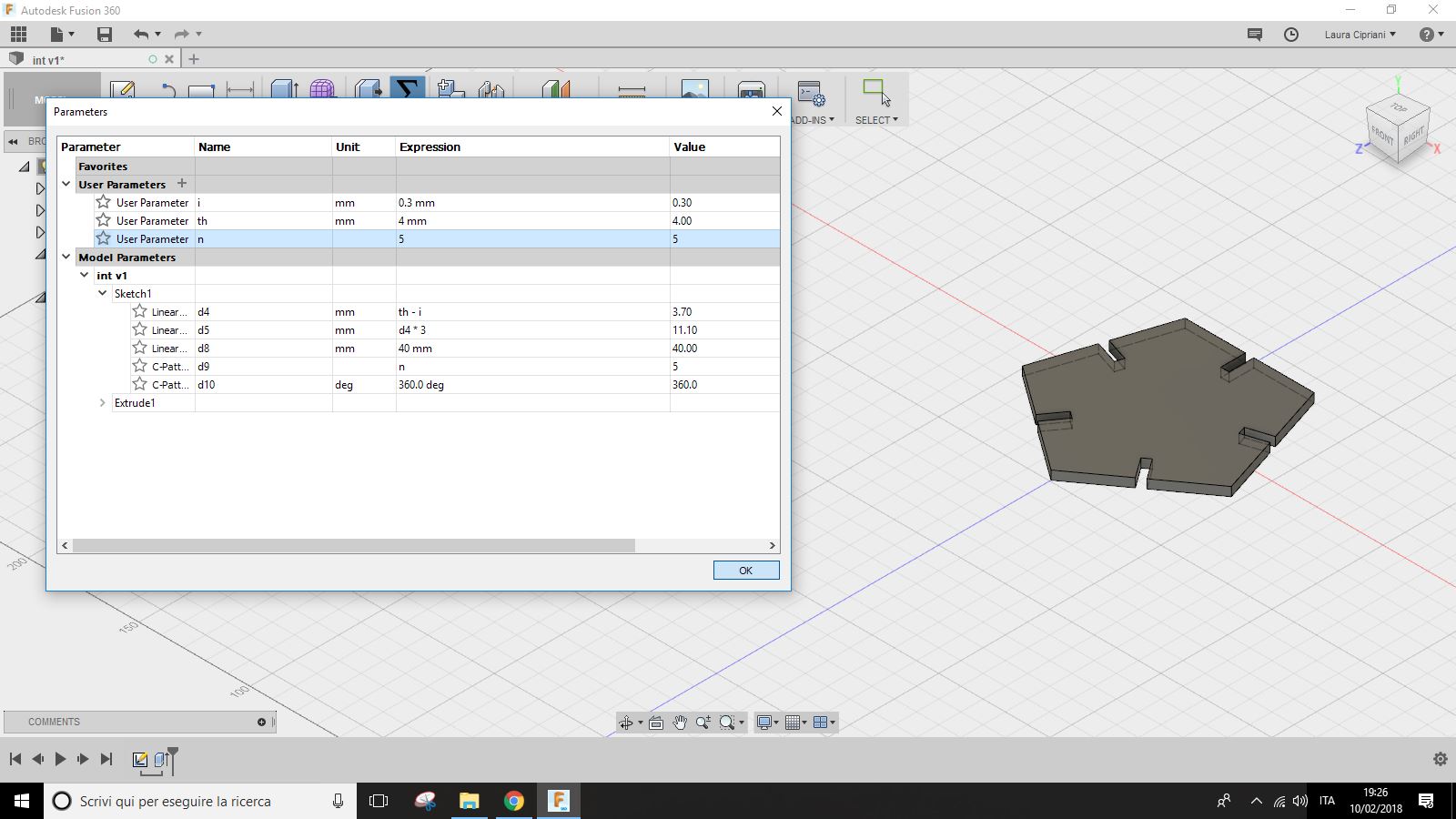

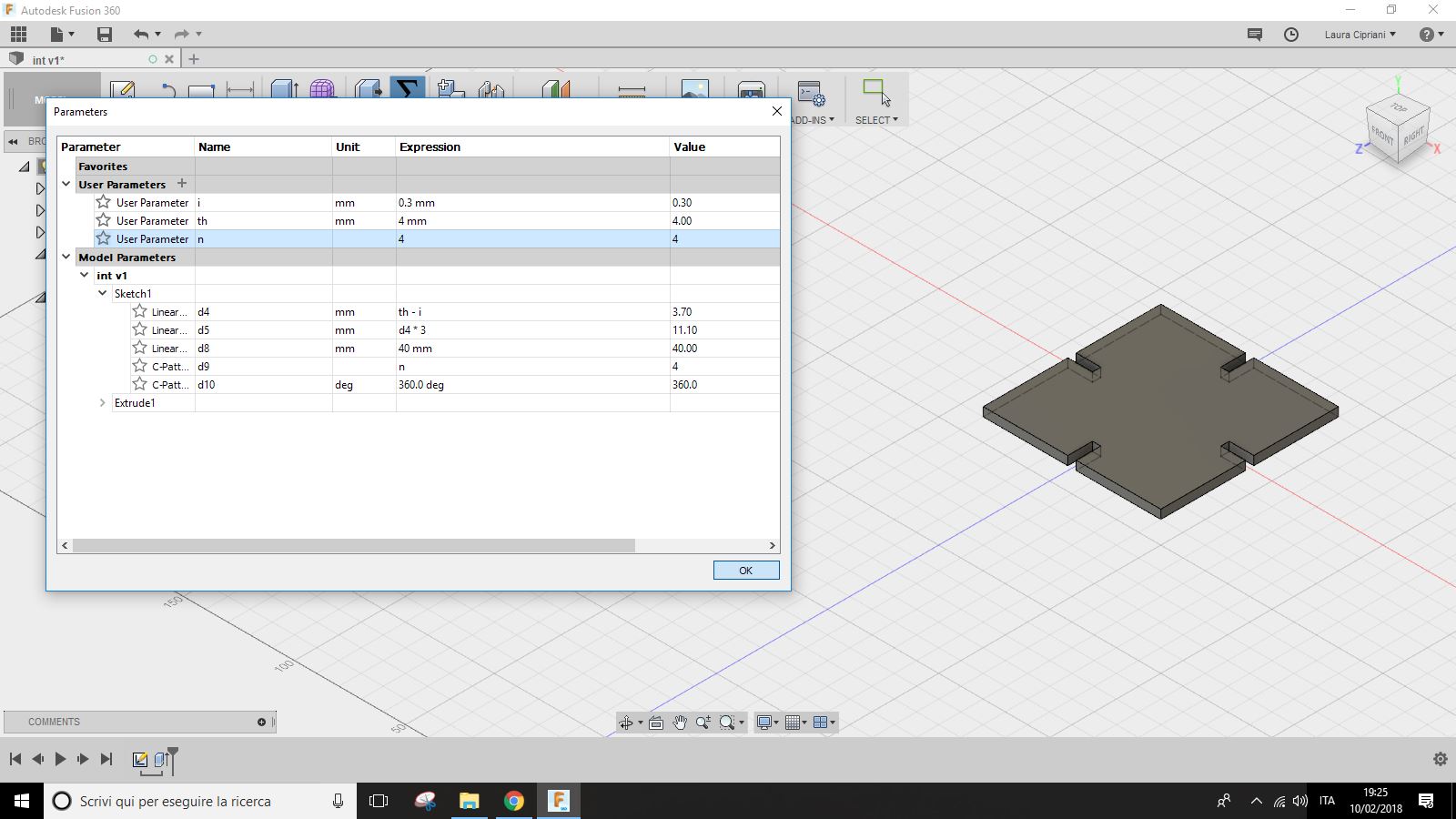

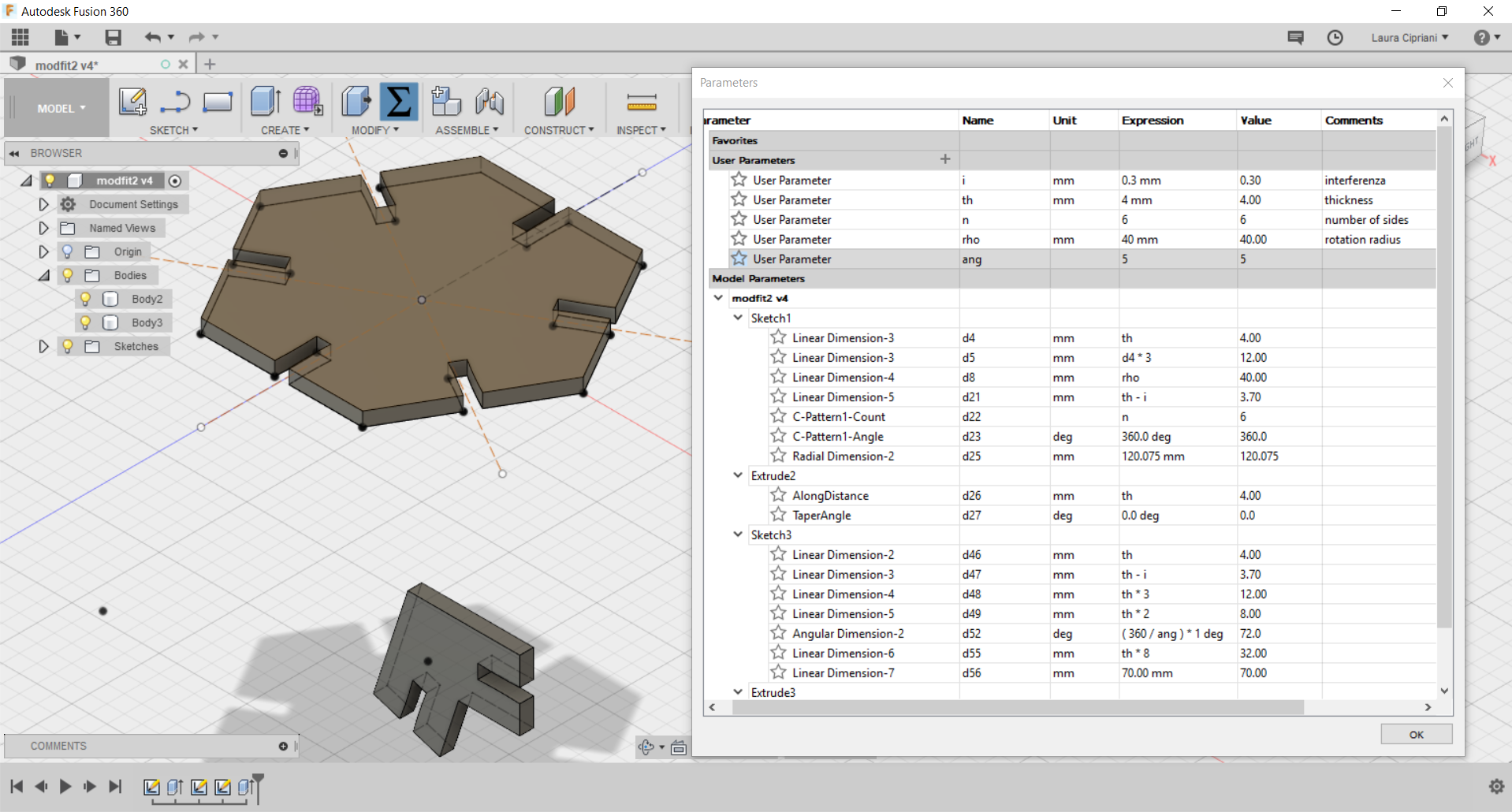

To realize this game it's useful to draw the puzzle pieces (the geometric one) in a parametric way: in this manner you will be able to obtain many different shapes with a single model. But if you want you can also draw without using parameters.

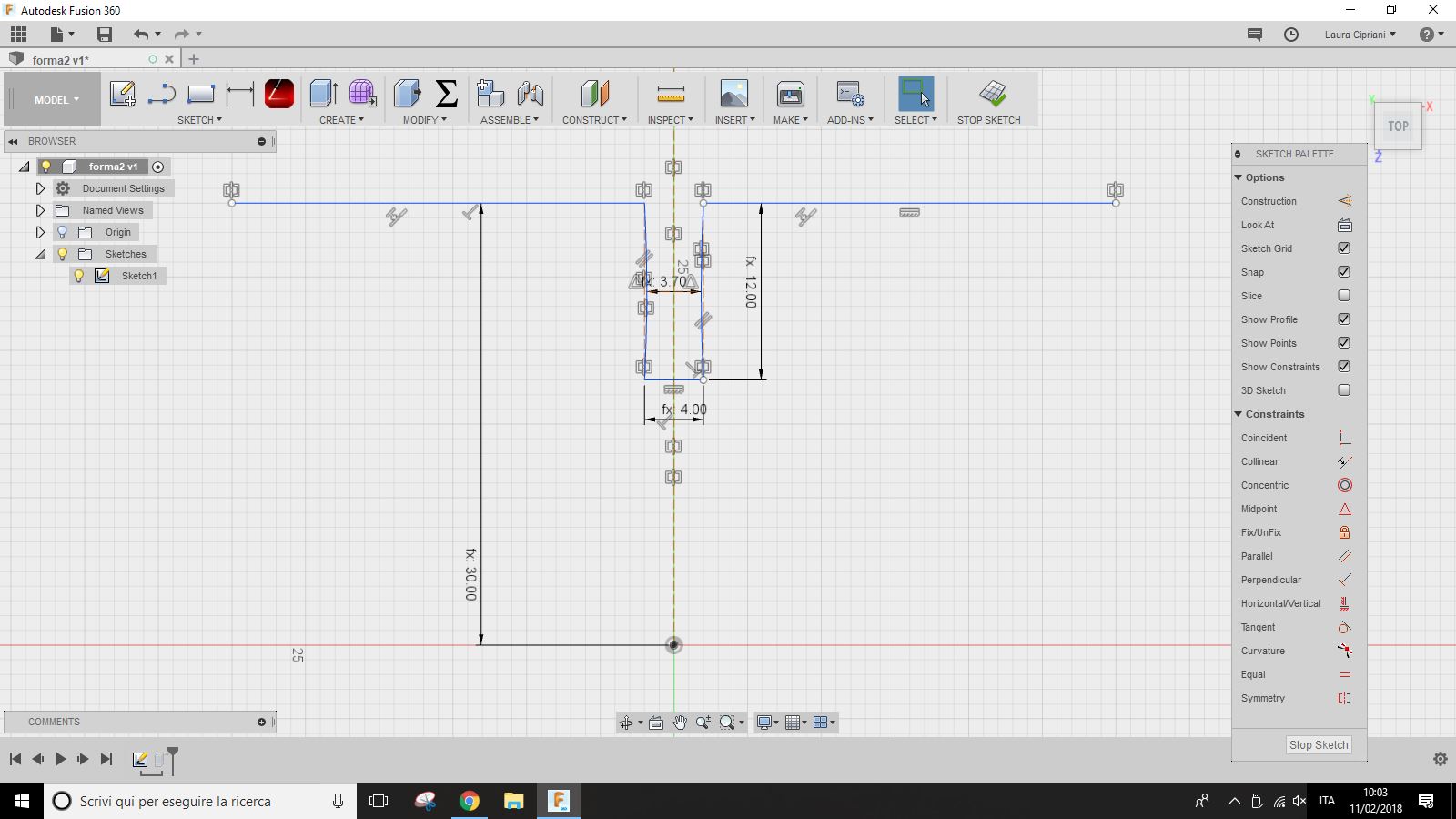

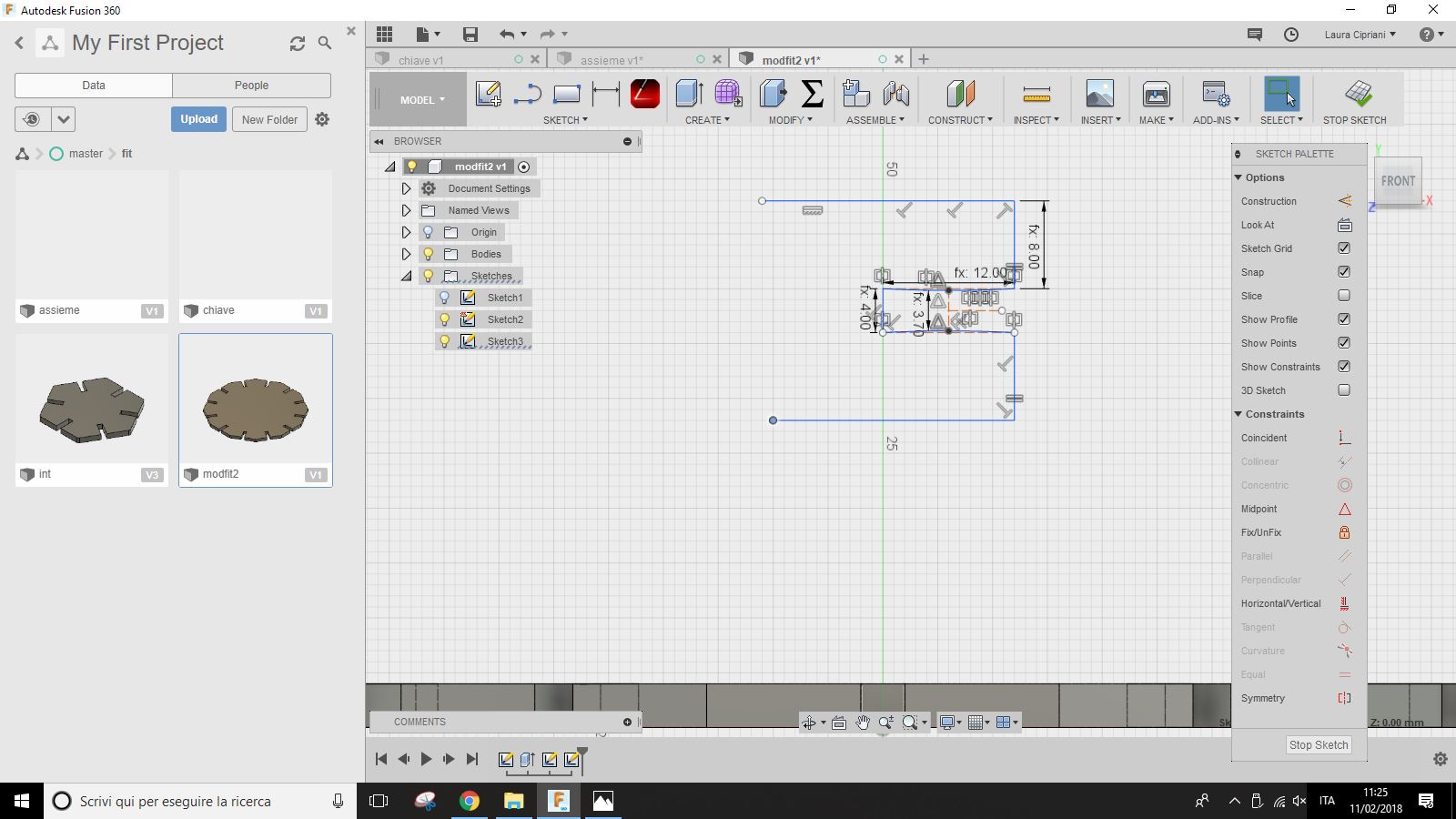

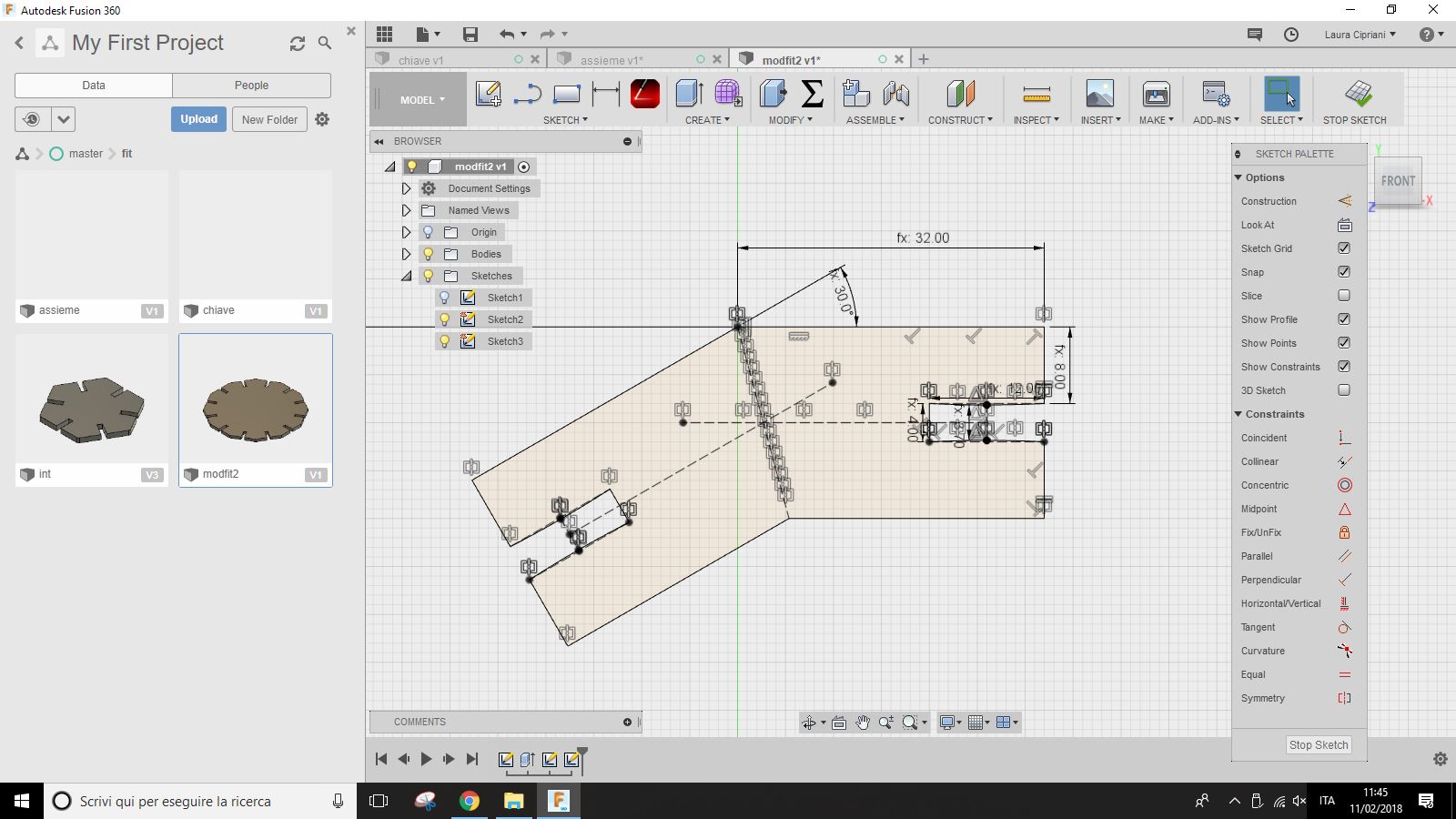

I started modeling the joint in order to constrain and parameterize the parts of the piece based on the thickness.

I started modeling the joint in order to constrain and parameterize the parts of the piece based on the thickness.

1.2 Model the joint part

Also for this piece you started setting the joint and putting the other dimensions according to the thickness of the material.

If among all the download formats choose "fusion" (.f3d) you can open the fusion model and see all the modeling steps from the history and all the parameters from "modify -> parameters".

1.3 From DXF to Lasercut CAM

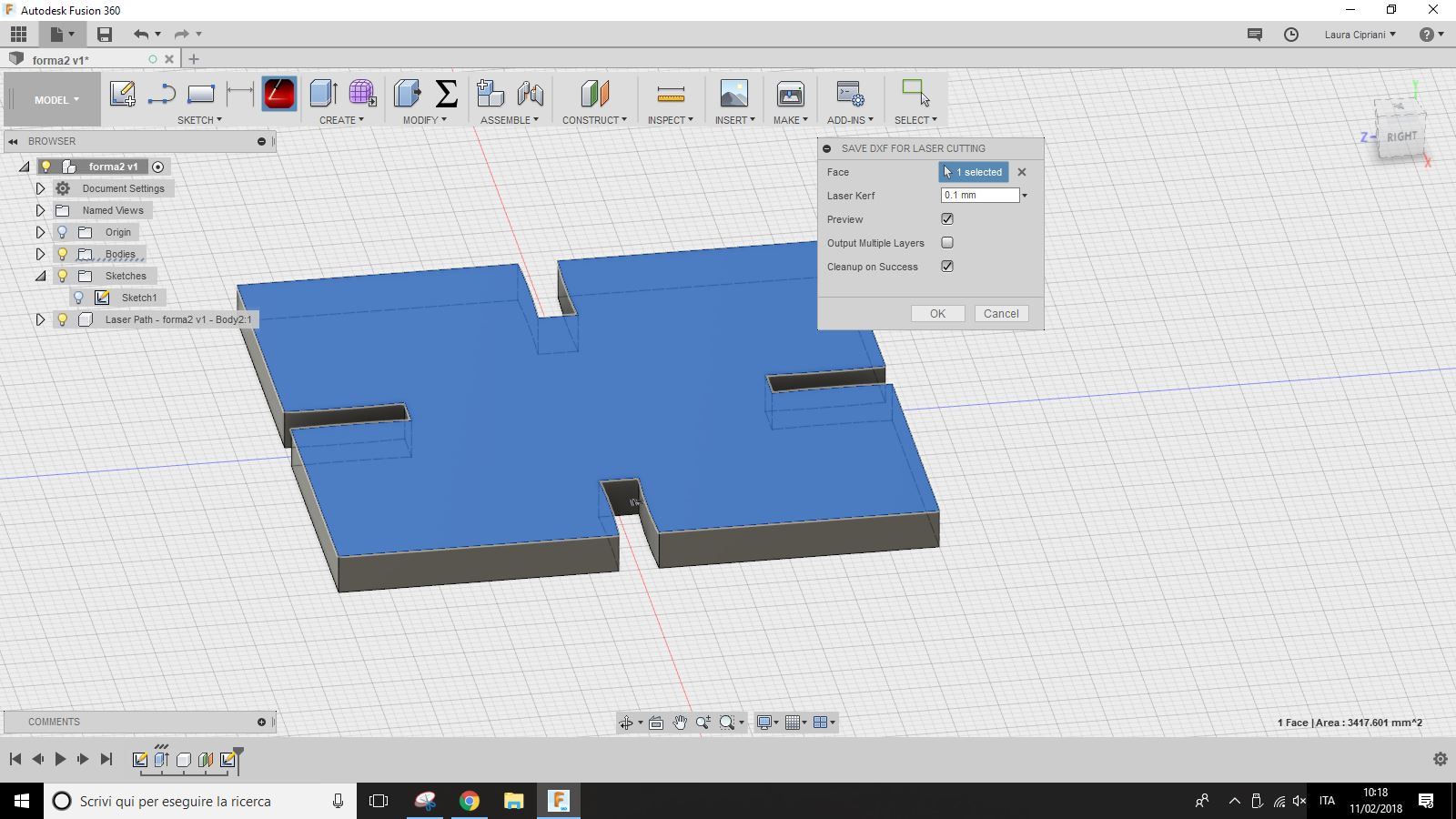

When you've got a .dxf file (which is a 2D model) you can proceed with the table setting. You can do this step with a vector graphics program (inkscape) or with a 3d modeling program (Rhinoceros). This depends on where the laser cutting machine drivers are installed.

At this LINK you can see the "starter kit" of Vectorialism (Italian lasercut service) it is very usefull for understand the logic of cutting and engraving layer in different softwarer: Inkscape, Blander, etc.

Then you can choose material: remember what thickness you made the joints! I chose to cut on a 4 mm thick plywood. I considered 0.1 mm of kerf (interference of lasercutter) when I exported my 3D model from Fusion 360 with the plugin DXF for Laser and it's done. I cutted everything with a Spirit GLS machine and using the print driver from Rhinoceros (I also did the nesting on rhinoceros).

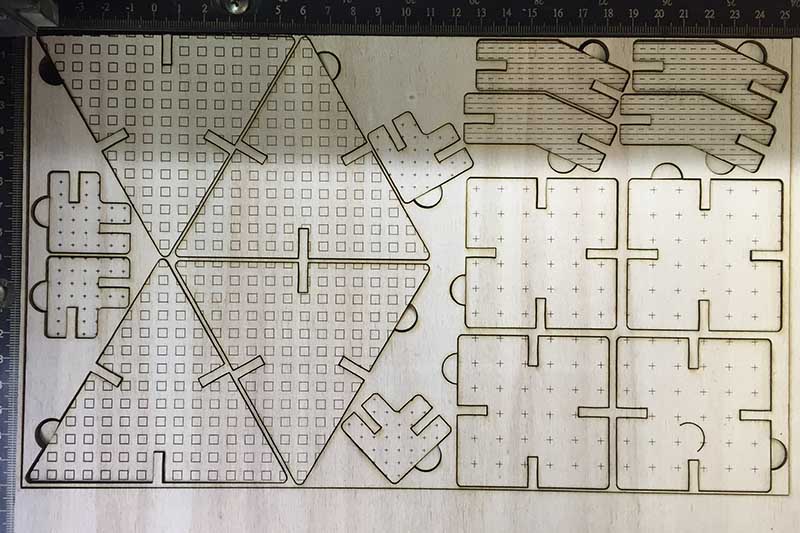

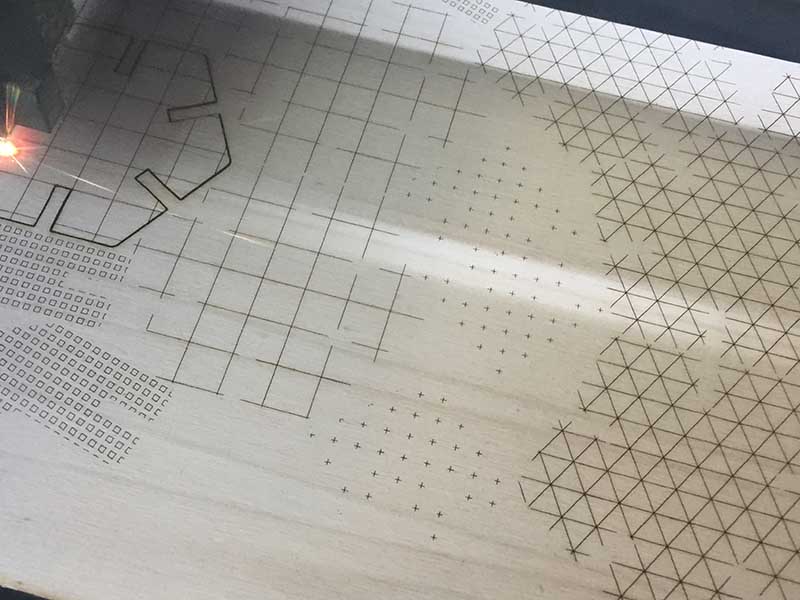

Before nesting I added vector fills in Rhinoceros to make a pattern on the different pieces. This is useful to make them more recognizable for children. I put in a level the screens for the engraving, in the second the cutting lines and in the third the rectangle of the board.

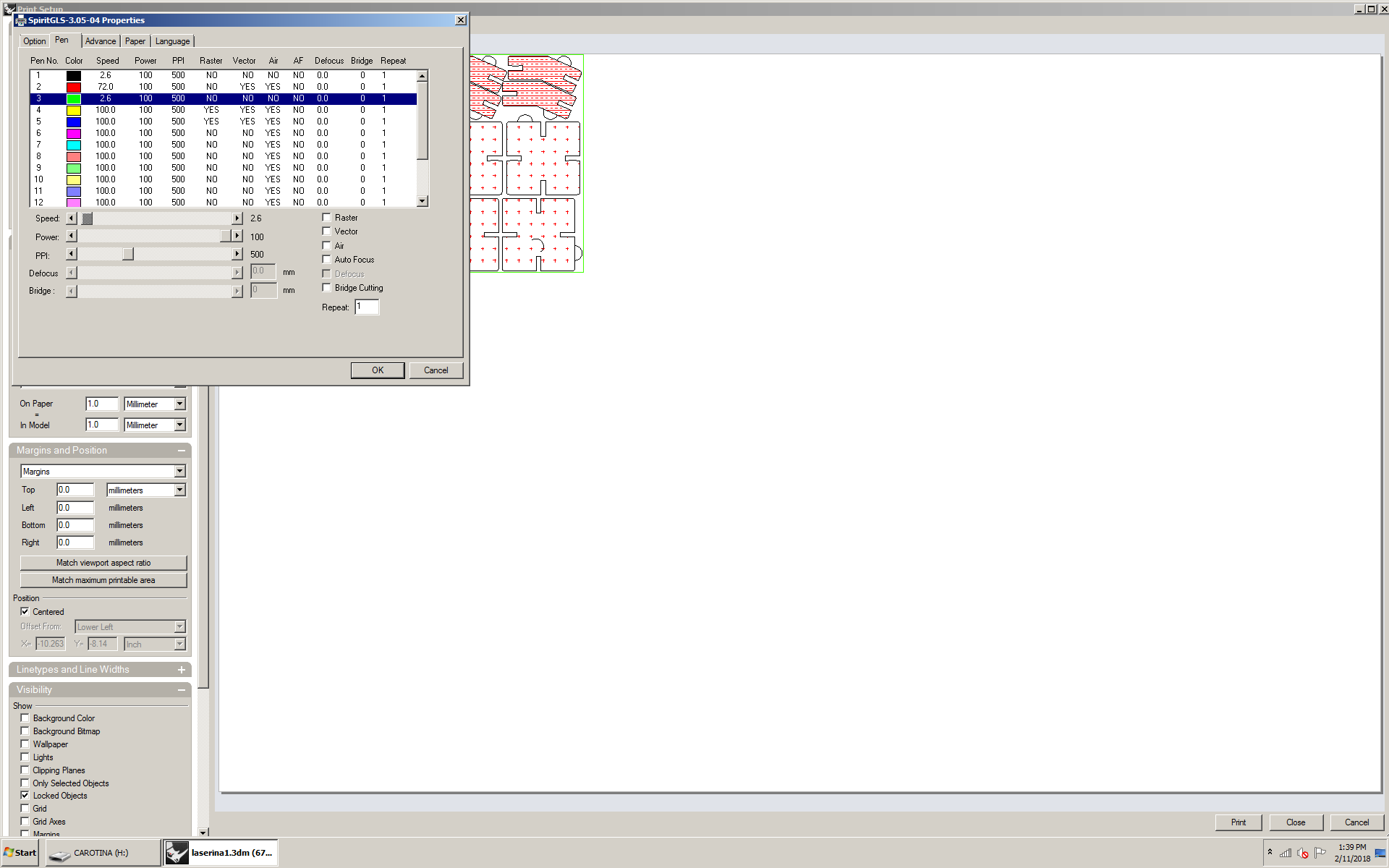

I assigned these cutting parameters to the laser:

During the nesting I also made some semi-circles useful for extracting the pieces, these can serve as a basis for the packaging.

During the nesting I also made some semi-circles useful for extracting the pieces, these can serve as a basis for the packaging.