| Seonghee Kim | |

| 16. Machine Design | |

| HOME | ABOUT | ASSIGNMENTS | FINAL PROJECT| CONTACT | |

-To see whole process of machine design click machine project.

-To see my mechanical design contribution(week15) click previous.

machine project

Week16

Assignments

-group assignment

- actuate and automate your machine- document the group project and your individual contribution

Hardware and Softwares used

-Arduino IDE

individual contributions and Outcome

-Test stepper moter code.-Test touch sensor and output with I2C.

-16 key touch sensor and LCD display code.

-to see my mechanical contribution click here.

Machine Automation

Stepper moter code

I had an experience to fail running stepper moter with c programming so I use .Test touch sensor and output with I2C

16 key touch sensor and LCD display code

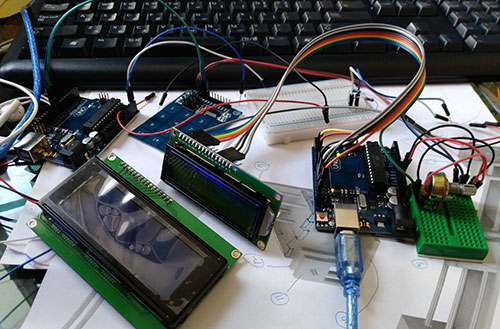

we are useing 2004 LCD with i2c/SPI character LCD backpack and TTP229 capacitive touch sensor. First I tested individuar board. LCD and TTP229 works well.

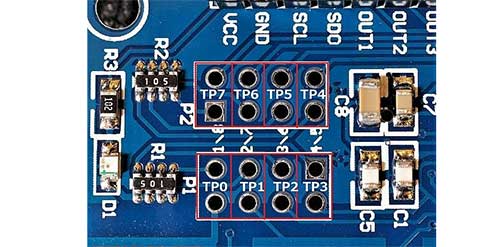

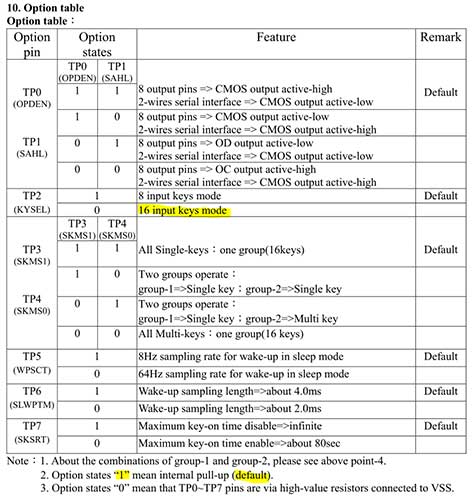

-check datasheet for TTP229. Option stats '1' means defalt. '0' needs to solder/jumper.

When I connected '2004 LCD with i2c/SPI character LCD backpack' and 'TTP229 capacitive touch sensor' at one Uno board, it did not work.

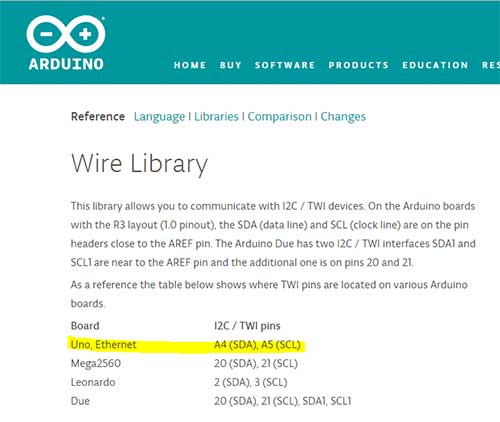

I put common SDA in A4, SCL in A5. but the board did not work.

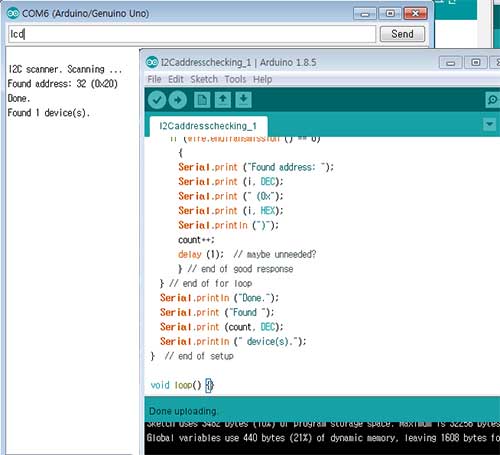

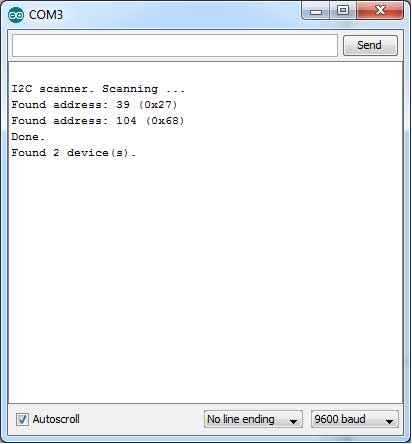

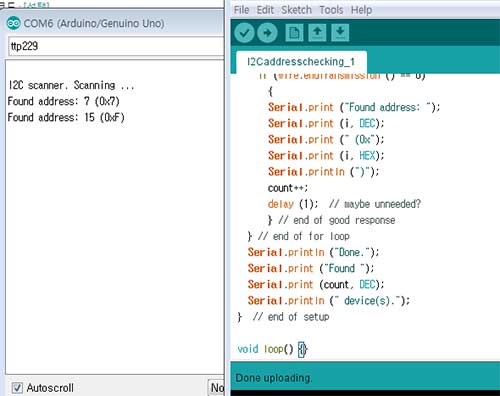

I run I2C address scanning code to know exact address of each board.

-LCD with I2C can get its address exactly. but TTP229 changed whenever I did and sometimes did not show up at all.

-LCD with I2C can get its address exactly. but TTP229 changed whenever I did and sometimes did not show up at all.

-it was hard to find a exact address of each board. So I decied to use 2 arduinouno board. But it did not work again.

-it was hard to find a exact address of each board. So I decied to use 2 arduinouno board. But it did not work again.

-Due to lack of time, I changed the button to 4x4 Matrix Keypad. and it works well.

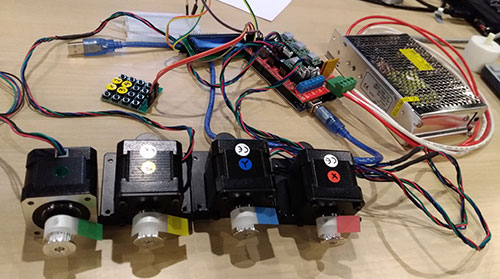

Motor control with RAMPS.

Setup all funtions for ready.

-On arduino mega board with RAMPS, I set up keypad, LCD, 4 step motors to run.

Native Programming.

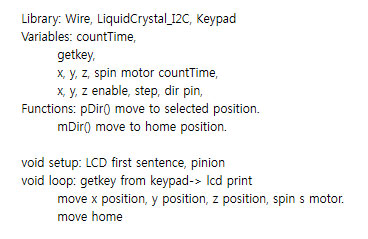

Last Coding works with YoungSik. First, we discuss about the programming process. Then check with the mechanicla part step by step.

-Click here to download file(machine.ino).

-reference1, reference2

Date: 2018-05-06 Author: Seong Hee Kim @ Fablab Seoul