FINAL PROJECT

What does it do? Who's done what beforehand? What did you design? What materials and components were used? Where did they come from? How much did they cost? What parts and systems were made? What processes were used? What questions were answered? How was it evaluated? What are the implications?

What will it do?

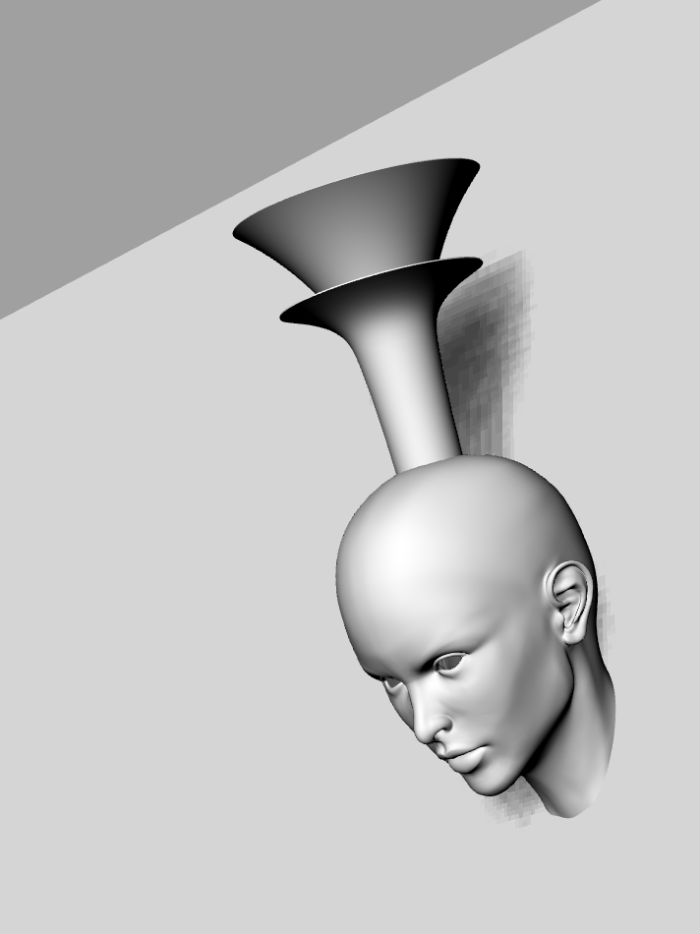

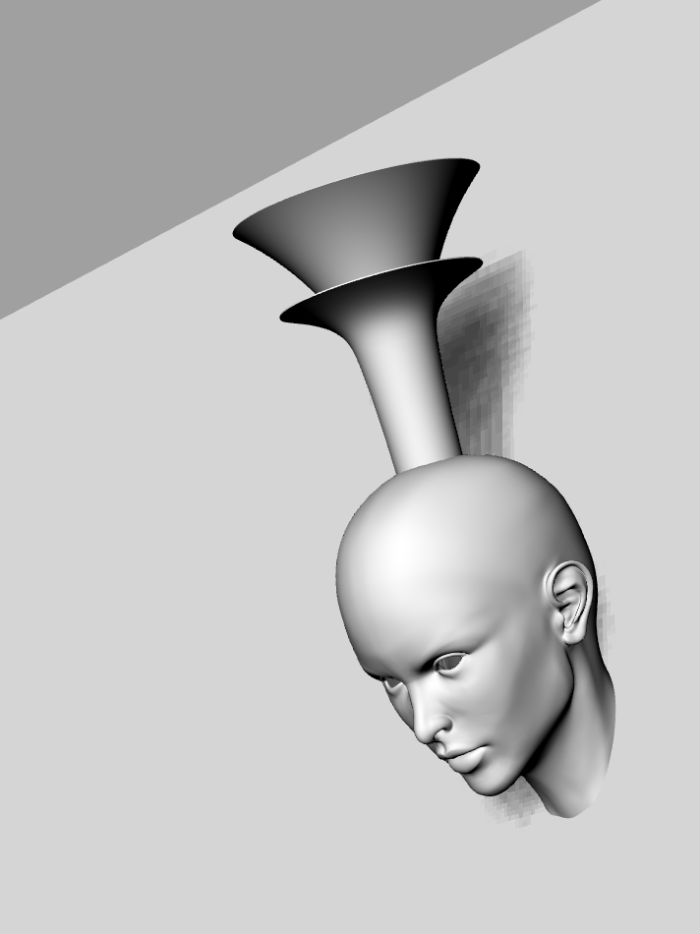

It will be interactive sculpture on the wall. Trumpet will be turned and make illusion when it sense the motion. I intend everyone and everything can affect me and I got motovation from them.

Who's done what beforehand?

Numerous interactive artist created pieces with similar idea. The idea is sensor sense motion and something moves or change.

What will you design?

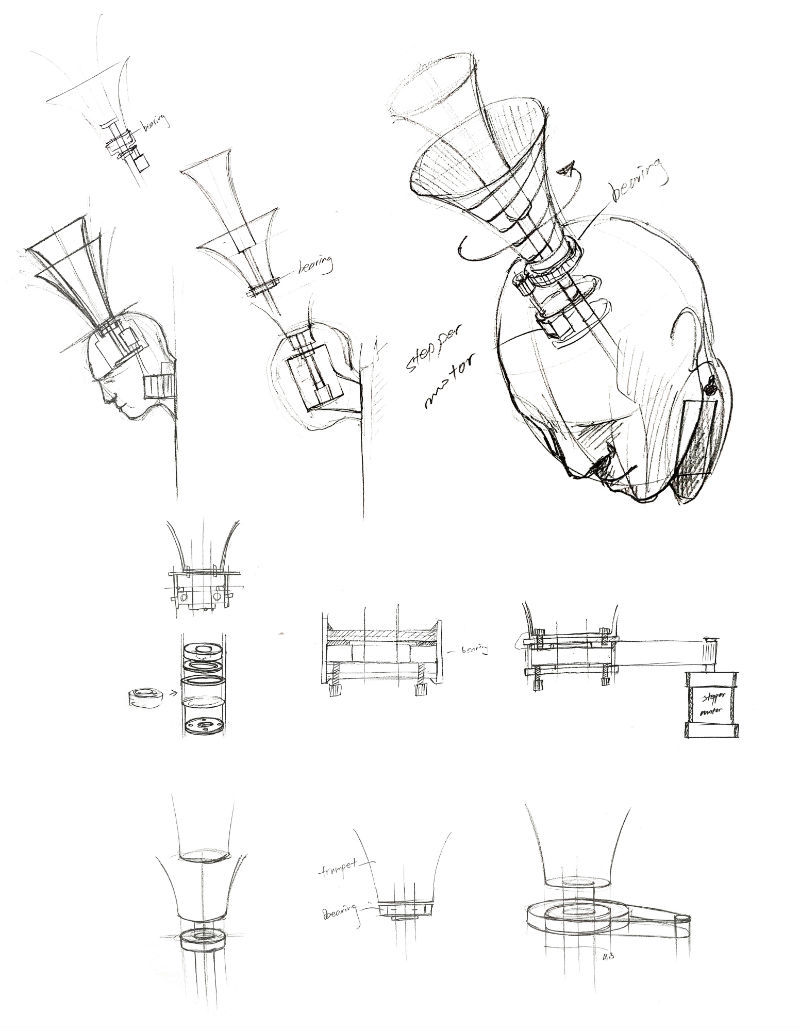

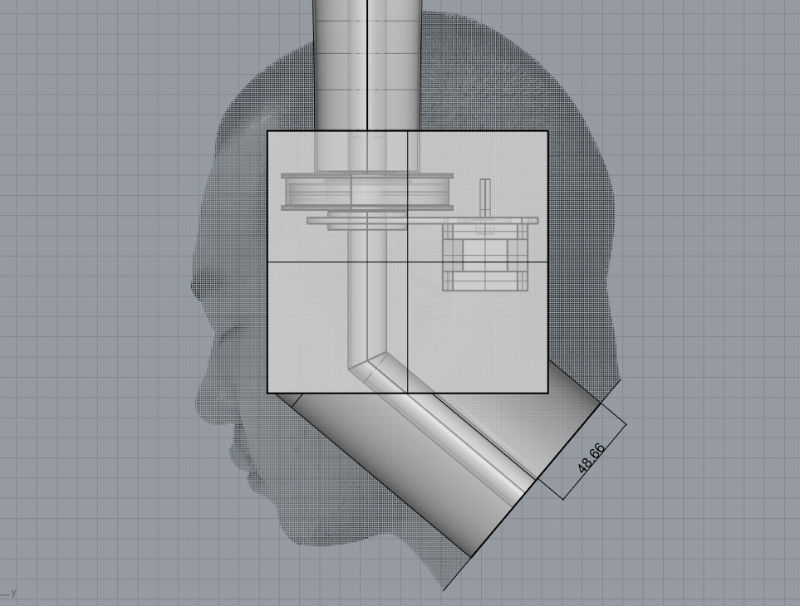

I’ll cast my head and put trumpet on it. Then one of trumpet will turn, so those trumpets have same shank and there will be bearing to hold shank and rotating bearing. I designed structure like this.

Where will they come from?

How much will they cost?

What materials and components will be used?

Im writing down every material fee and until now I spend about US$209

Buy from vender

- aluminum rod 90t- $40

- aluminum spined trumpet - $20

- 0.75" stainless steel pipe 1000mm - $6

- 3t stainless steel laser cutting - $25

- 0.75" 1.62" bearing - $9

- timing belt - $3

- silicone for casting - $40

- aluminum powder -

From lab

- silicone for life casting - $66

- components

--

--

Total - $209

What parts and systems will be made?

What processes will be used?

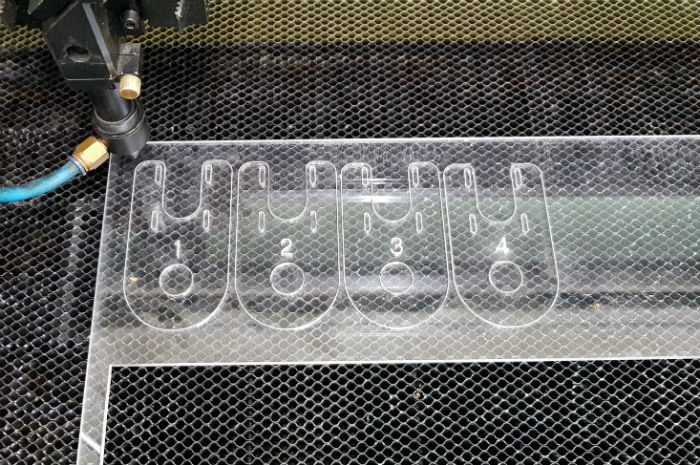

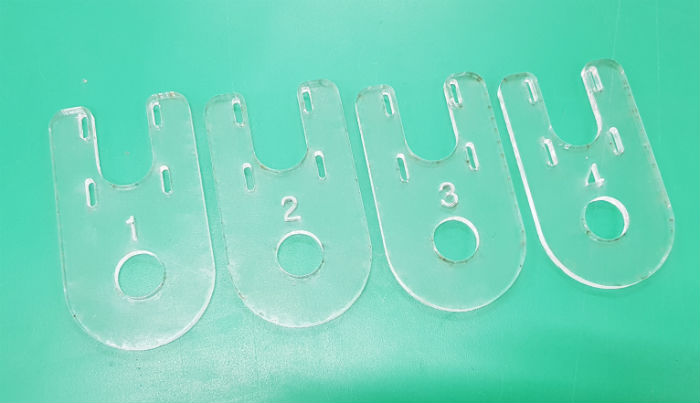

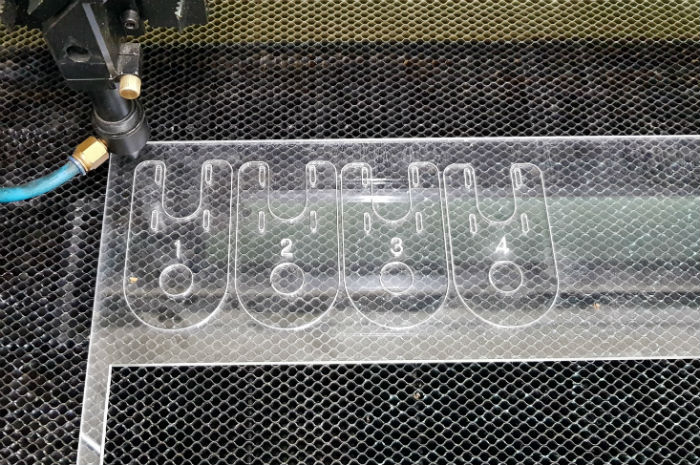

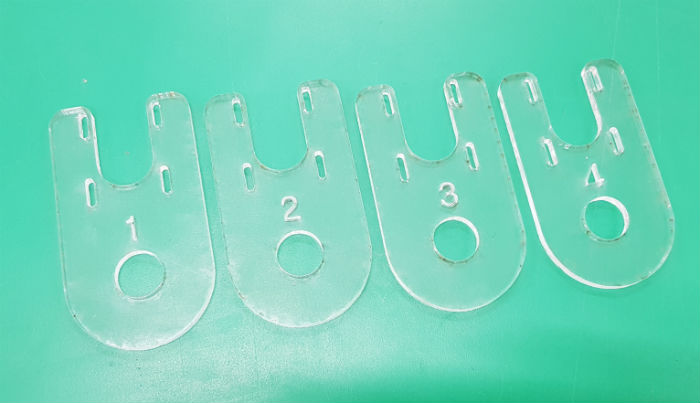

Laser cutting (acrylic 5t, stainless steel 3t)

- acrylic cutting for sampling to measure distance from motor shank to pipe. and stainless steel laser cut plate will be exact part of my work.

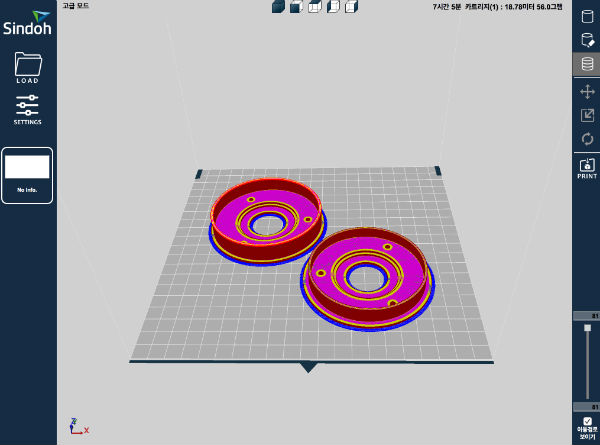

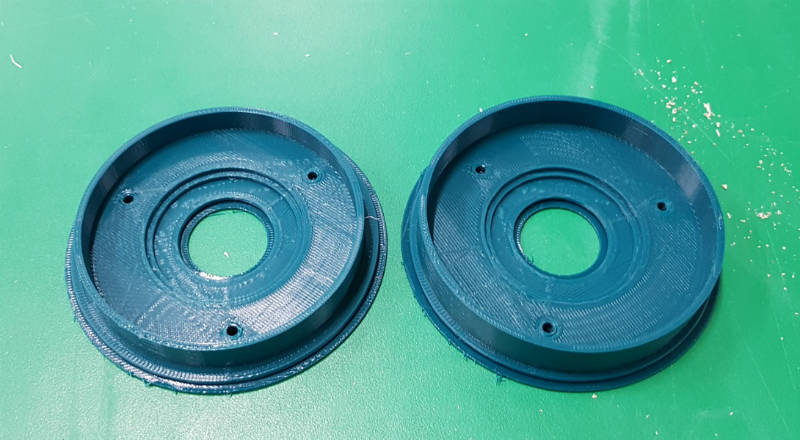

3d pringting (PLA)

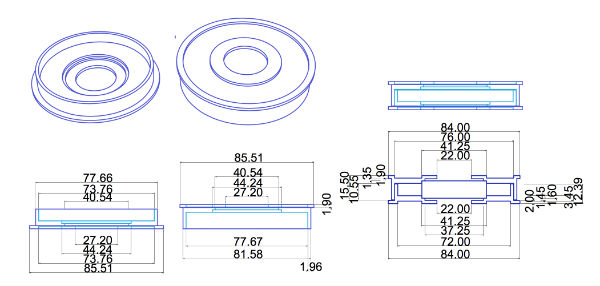

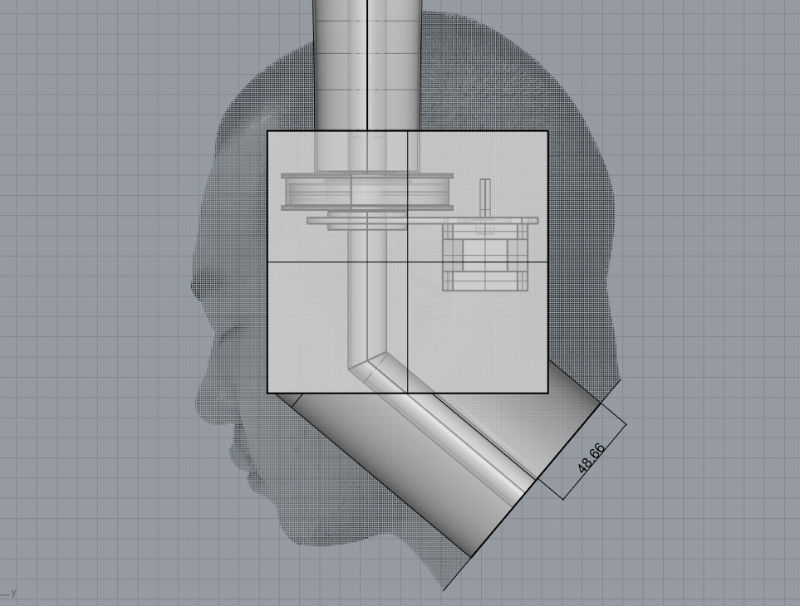

- baering will hold pipe at the hole and i need some part to hold bearing's outer part that will be jointed with outer trumpet. So i tried to make mock-up with 3D printing.

It looks like this.

Molding and casting (silicone)

- I'll cast my head with silicone for life-casting.

Welding (stainless steel plate)

- these metal rings will be welded to pipe to hold trumpet.

and this part will be welded to pipe also and hold motor.

Lathe machining (stainless steel pipe, aluminum rod)

- Metal pipe isn't perfect to put inside the bearing so i should make exact diameter with lathe. and i'll machine aluminum to hold bearing and timing belt.

Metal spinning (aluminum plate)

- To make trumpet shaped metal, there is machine that called spinnig machine. It is similar to lathe but it isn't subtractive method, but it's just transforming the metal plate with spin and presure.and the templetes are like this it's steel.

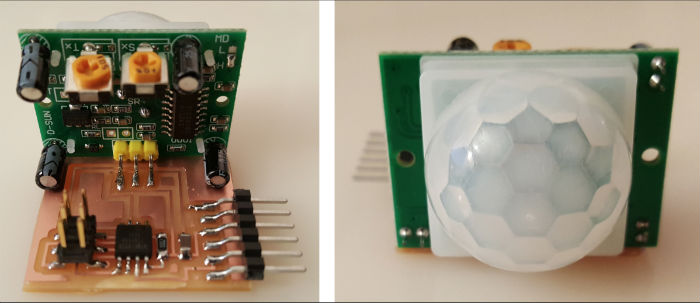

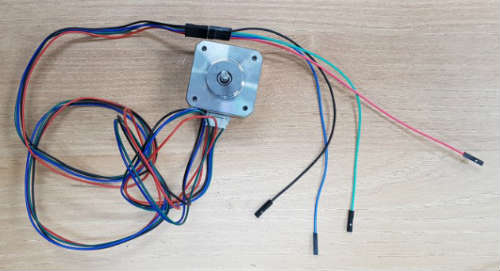

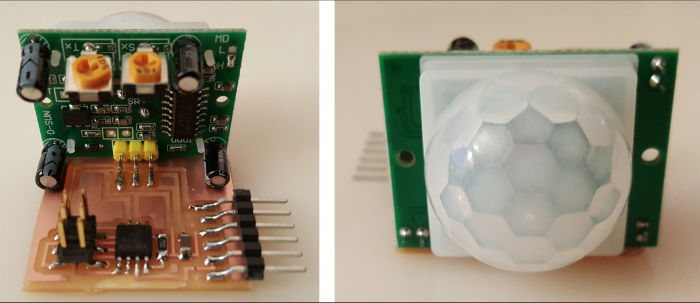

Milling, soldering(FR4 pcb board) and programming

- I should design motion sensor board and motor driver board in one board. And solder all the components. also I should program it to sense and turn. I'll make it turn continuously and when the sensor catch motion it will turn faster than usual.

What questions need to be answered?

How can I bury every part inside the silicone?

- My plan is to make case with pomax and bury it inside the silicone to protect all the parts from silicone.

How can I make silicone looking like metal during its texture like skin?

- I searched for many tutorial video of metal powder cold cast. but there is only one video that cast flexible material with metal powder. so i should do a lot of experiments. and here is the video.

How will it be evaluated?

I hope my work will be evaluated by everyone who saw the piece. Every part should work their character well and affect well. Piece will have exact same appearance with myself and I hope people can feel like communicating to me.

Which was done before and how long did it take?

I started my final project at mid of May. and progress every single task one by one.

First, I made two trumpets, and bought bearing and shank.

I measured those every sizes and put them into model on Rhino.

So I drew modelling for bearing holder, connection part for shank and trumpets.

Then I printed bearing holder with 3D printer.

I bought timing belt to rotate bearing holder connected to one trumpet.

and lasercut acrylic for motor holder to test proper distance from bearing holder to motor shank. Because timing belt was fixed. So I made 4 different sizes and first one was fit to motor.

For casing, I did lifecasting with my head. I used safe silicone for skin from Smooth-on.

But, It was too thin. It wasn't fixed well.

Next step(All the process will be posted on final-project page.)

3D printed bearing holder was fine but I should use harder material than PLA. I decided to make bearing holder with aluminum. So I will machine with lathe aluminum rod.

And I will laser cut stainless steel 3t for connection part for trumpets and motorholder the first one.

I should cast my head again with more silicone than before to make thicker mold.

Also I should design the board with PIR sensor and stepper motor.

June first week 6/1,2

board design and components soldering

June second week 6/3~9

programming

fabricating every parts except casing

June third week 6/10~16

molding and casting for casing

finishing

WHERE I WORK

I'd love your feedback!

Phone: +082 1041950935

Email: jshjshjsh93@gmail.com

Feel free to contact! , or leave me a note: