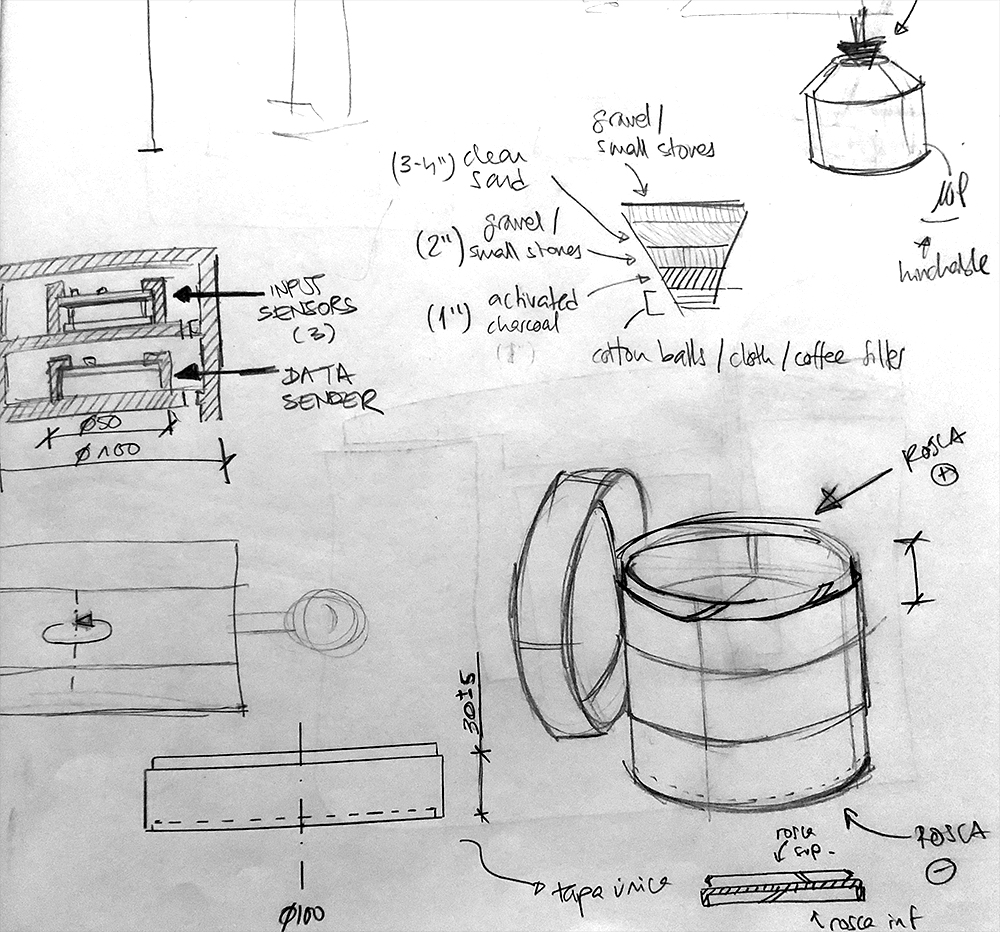

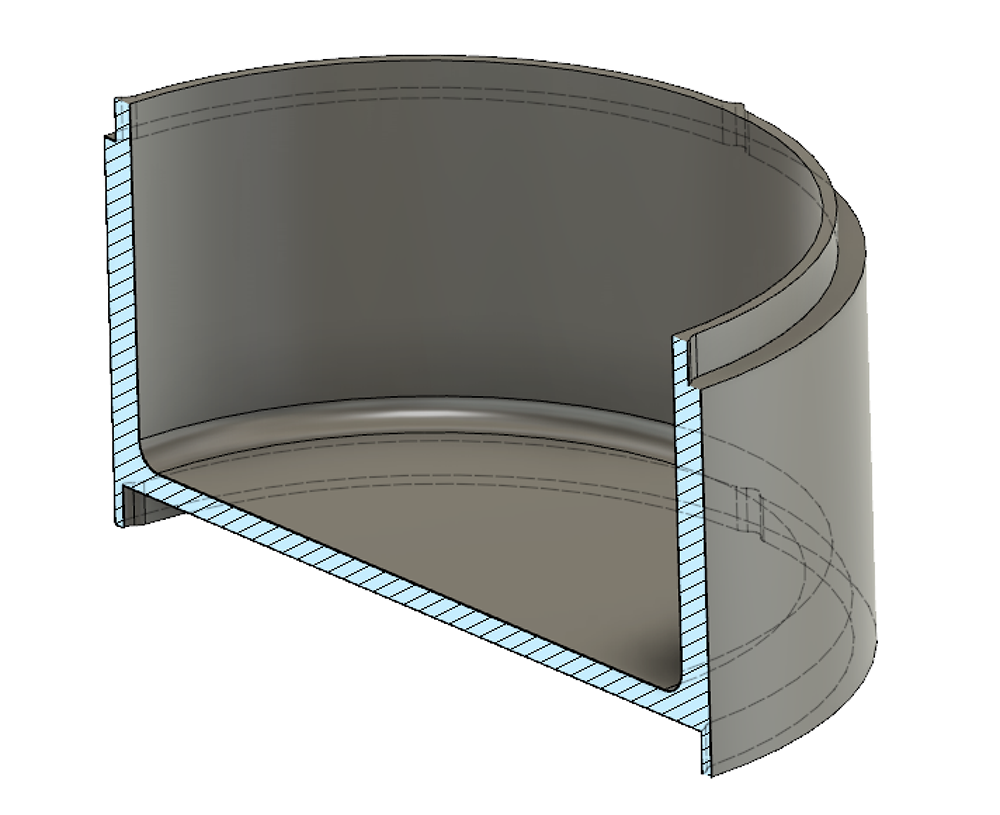

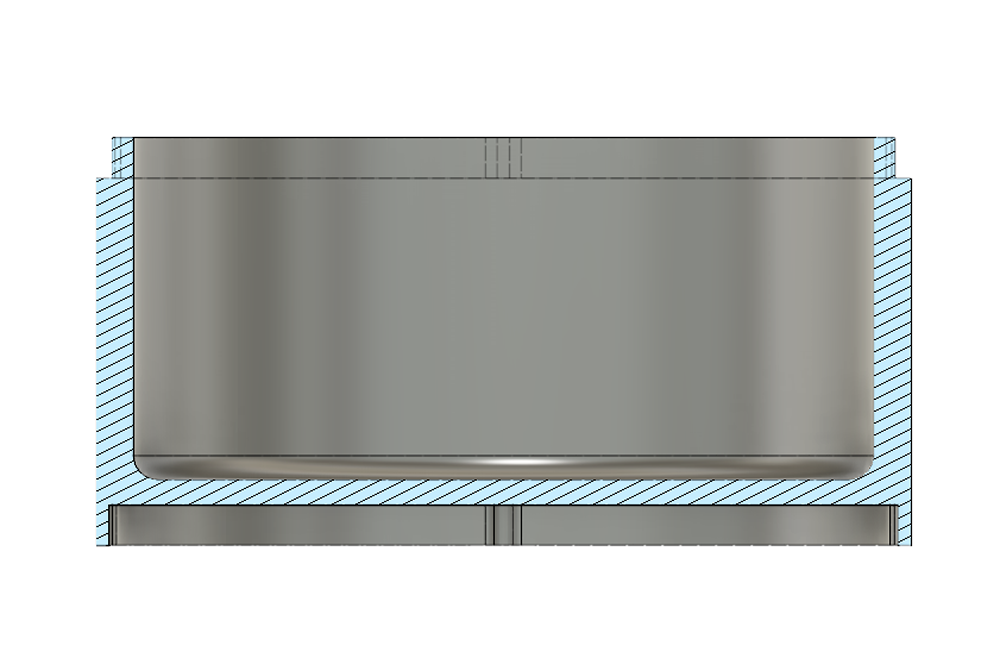

First I am using Fusion360 to make the model of the casting. Here there are some general and section views of the model:

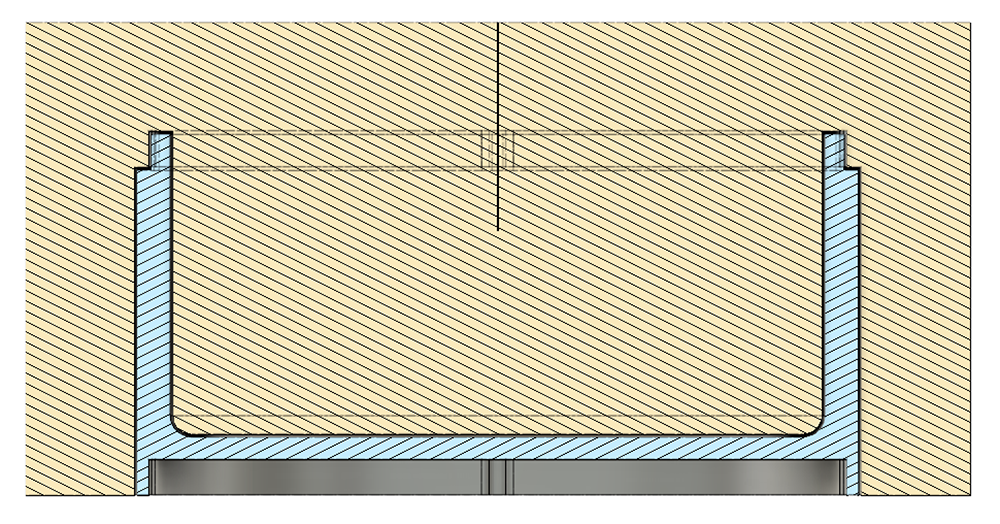

On the next image, there is a partial view of the casting model inside the mold.

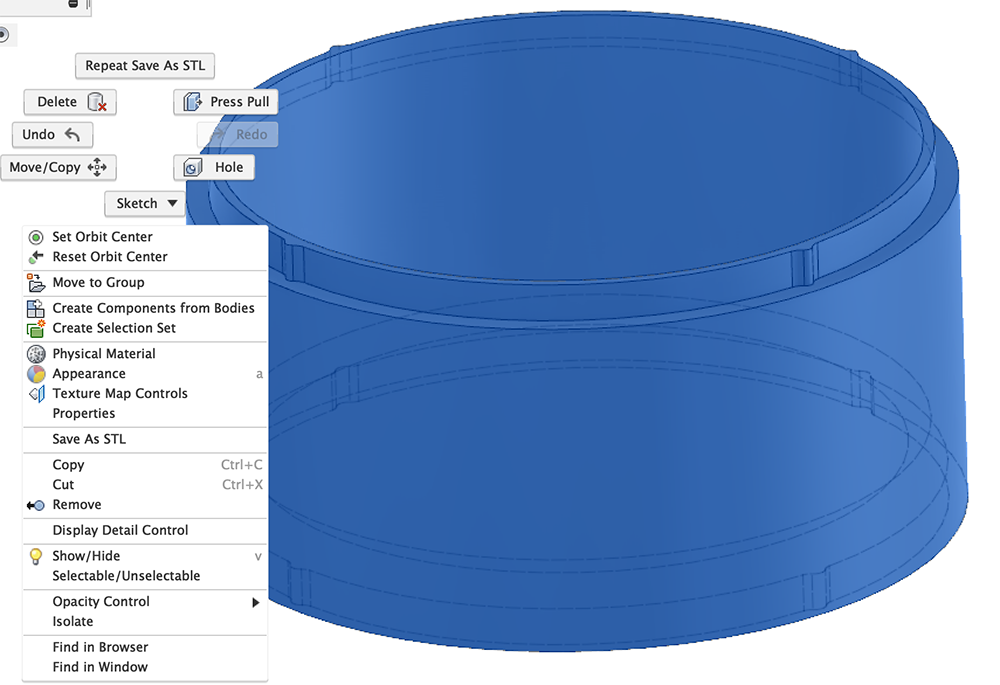

Finally I am saving the casting model in .stl format:

Then I will use TinkerCAD to create the mold: