The process of laser cutting starts with a 2D design of the model. This model it will be uploaded to the Lab's Cloud to be processed by any computer and machine in the room.

The files can be opened in the computer nearby the machine first with Rhinoceros. The next step, should be importing the files and assigning the colors and layers to the parts of the model that can be operated in 3 different ways: cutting, engraving and rastering.

In the same workspace, the cutting area must be setup, as well as the printing settings, to define the material and thikness of the board.

Then the material to be cut should be placed on top of the cutting board, aligned with the upper-left corner where the laser focus is set as origin. If necessary, painter tape may help to stick the board flat to the borders to avoid from bending, because it would affect to the cutting efficiency in terms of power.

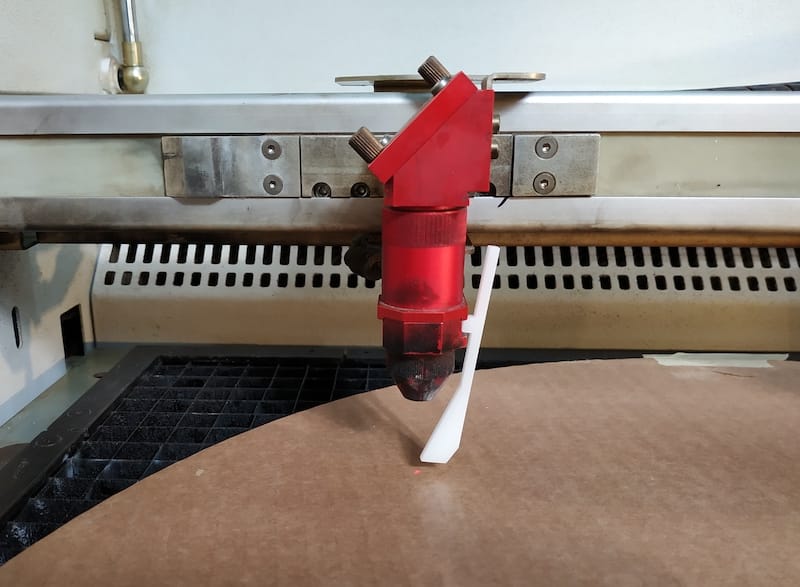

Before starting the machine, we must be sure that the air extractor is on, and also focus the machine with the caliber piece shown below.

These are the first testings made in cardboard (4mm) and plywood (4mm):

The setting used for the different processes are the followings:

Cutting:

4mm cardboard: 50 (Power), 1 (Speed), 1000 (PPI)

4mm plywood: 75 (Power), 0.8 (Speed), 1000 (PPI)

Engraving:

4mm cardboard: 30 (Power), 100 (Speed), 1000 (PPI)

4mm plywood: 60 (Power), 100 (Speed), 1000 (PPI)

Rastering:

4mm cardboard: 80 (Power), 100 (Speed), 1000 (PPI)

4mm plywood: 60 (Power), 100 (Speed), 1000 (PPI)