.png)

Hi! Welcome to Week 4

This week’s individual assignment was to cut something on the vinylcutter, and design, lasercut, and document a parametric press-fit construction kit while accounting for the lasercutter kerf.

.png)

This week’s individual assignment was to cut something on the vinylcutter, and design, lasercut, and document a parametric press-fit construction kit while accounting for the lasercutter kerf.

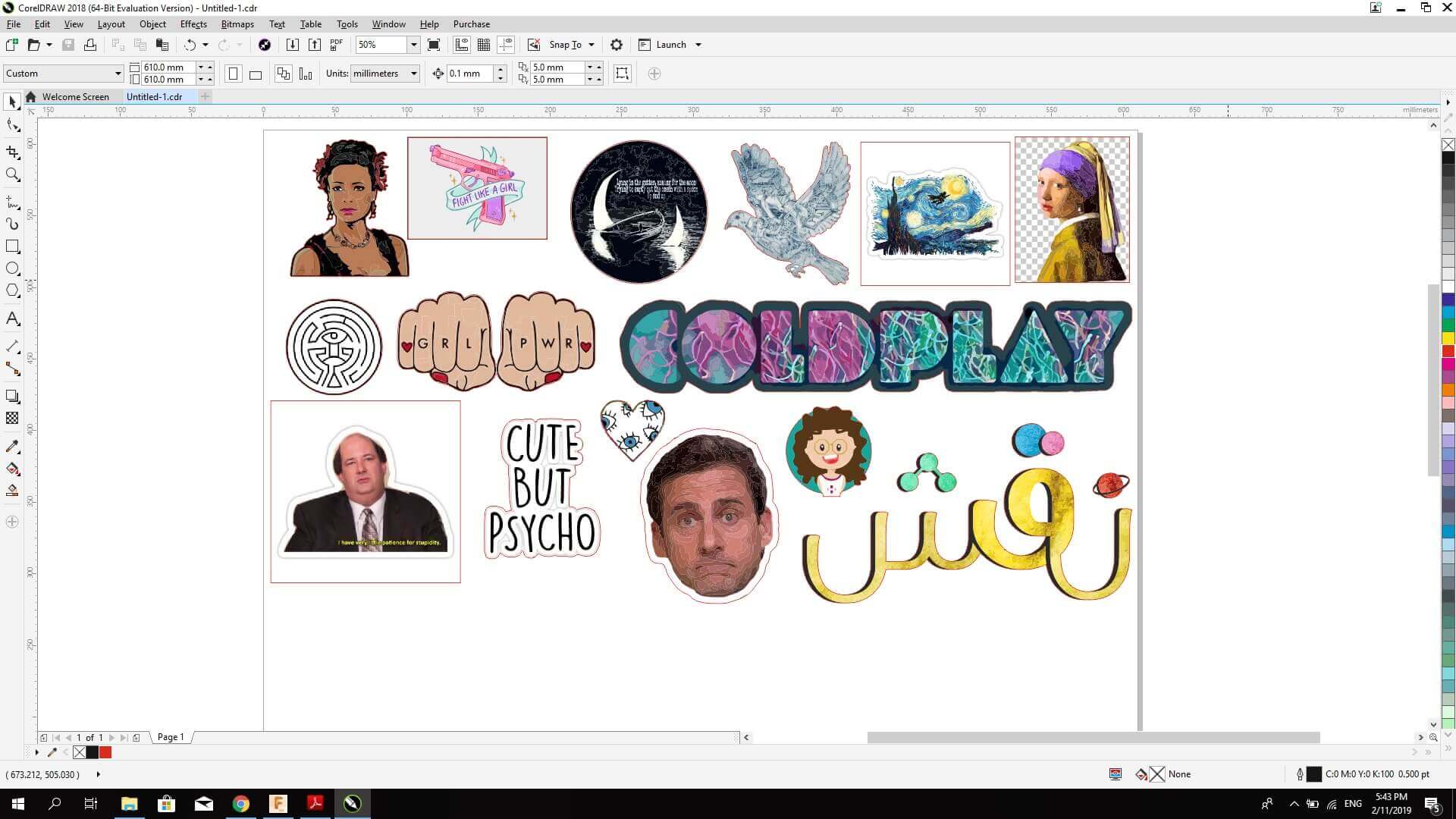

Vinylcutter:

I have previously used the vinyl cutter to print stickers. This week, I started by collecting the images I will be printing. To make things easier, I tried to find PNG images of what I wanted. Next, I used Corel draw to arrange them. I traced the outer lines mostly as high quality images and deleted the original ones. Then selected each object separately, wen to object, shaping, boundary, and then right clicked on the red color in order to set these lines later as cutting lines. I should note that the thickness for a cutting line should be added as hairline.

Lastly, I saved the file as pdf which you can download from

here.

I opened the Roland VersaWorks Dual, and added the pdf file

and used this set up:

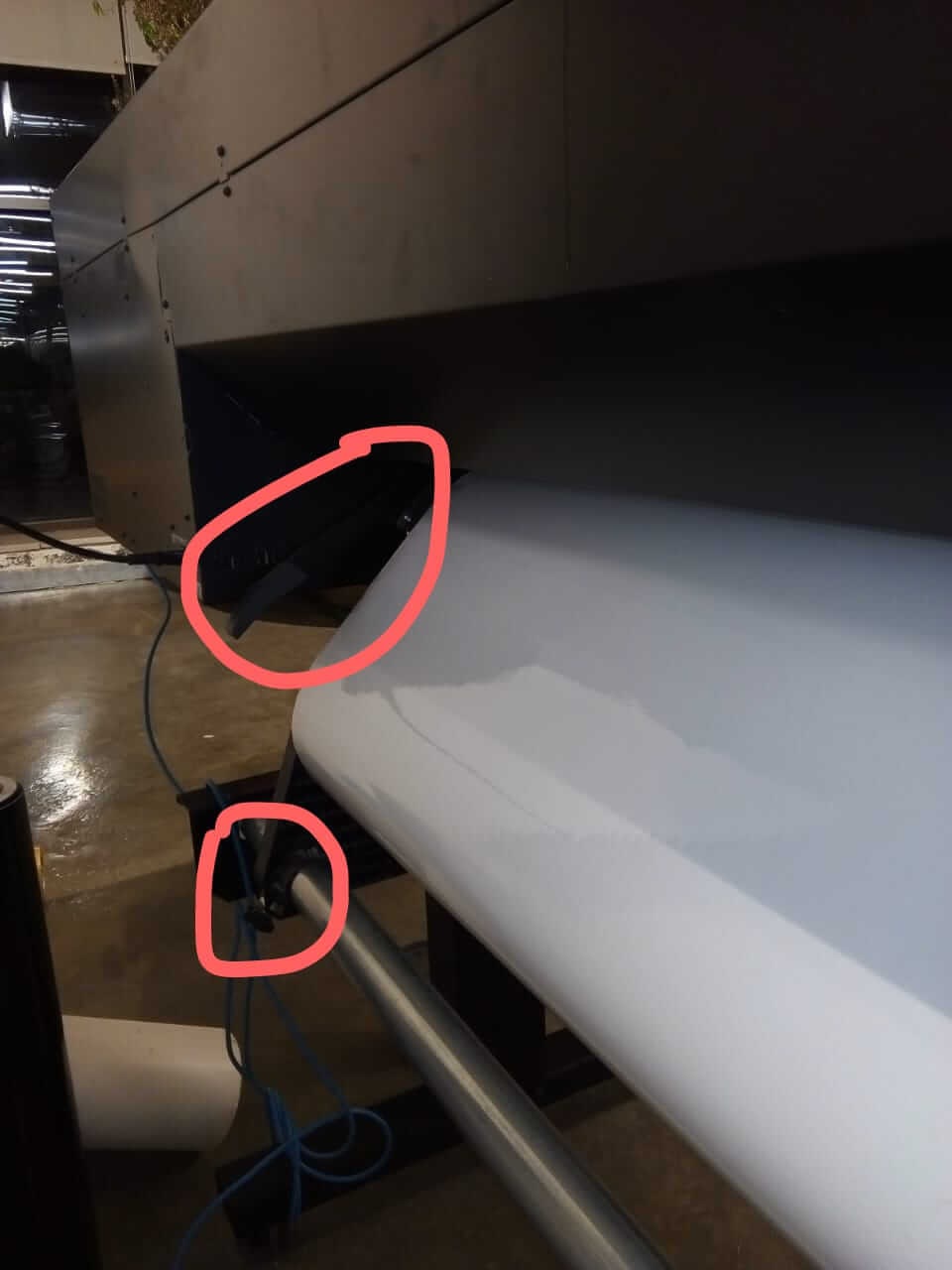

and saved the file. Before printing I wanted to change the printed stickers material from white to transparent and that’s how I did it:

I lifted the upper arm, loosened the lower bolt from both sides and removed the white roll and added the transparent roll. I headed back to the computer and gave the print order.

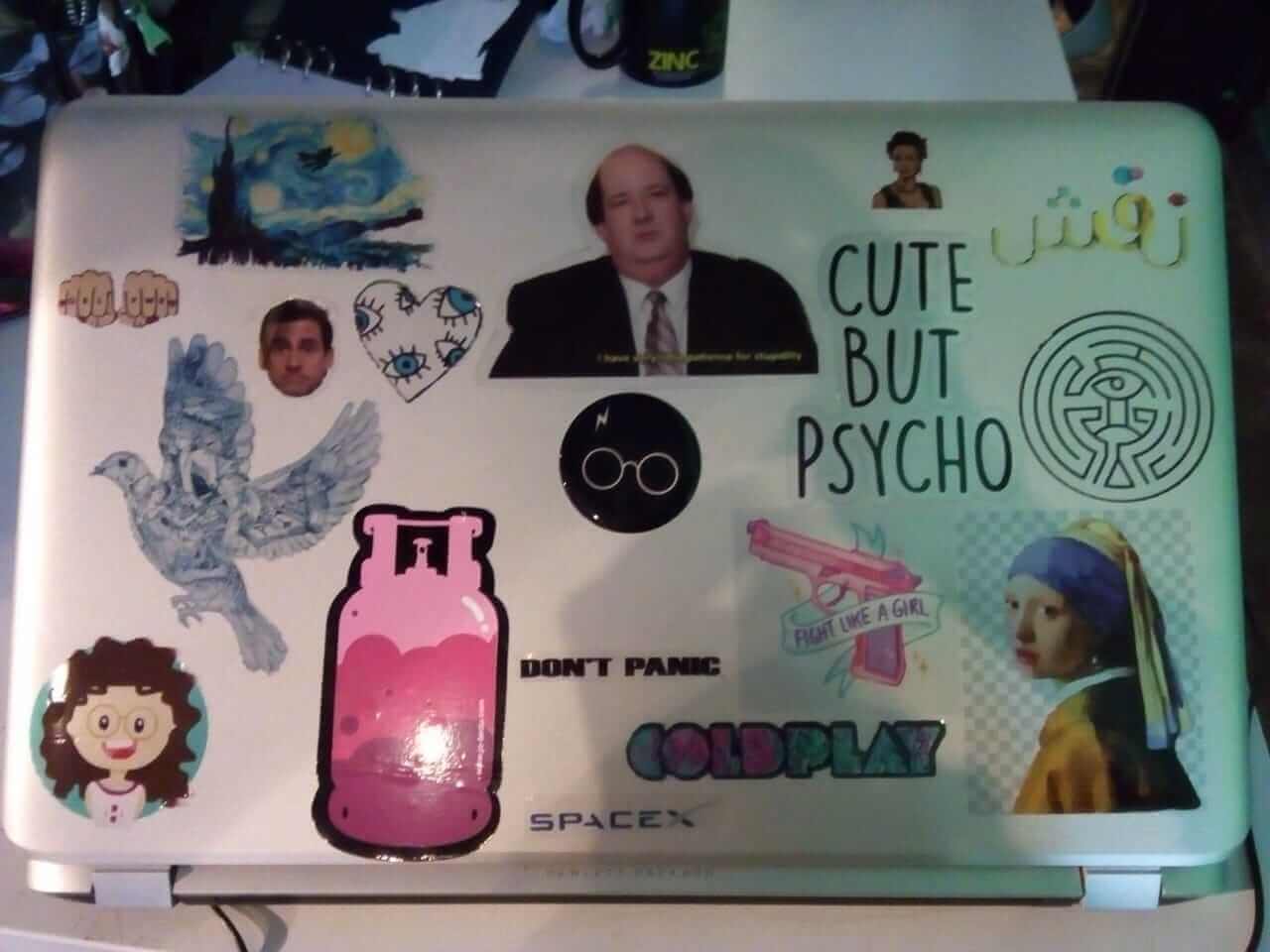

I found the first print to be huge in size and the stickers wouldn’t fit my laptop, so I scaled the size to 30% and printed again.

The print size of the second trial turned out to be really, REALLY small in comparison to the laptop.

Instead of printing again, I chose the size I preferred from each sticker and put it on my laptop.

Laser:

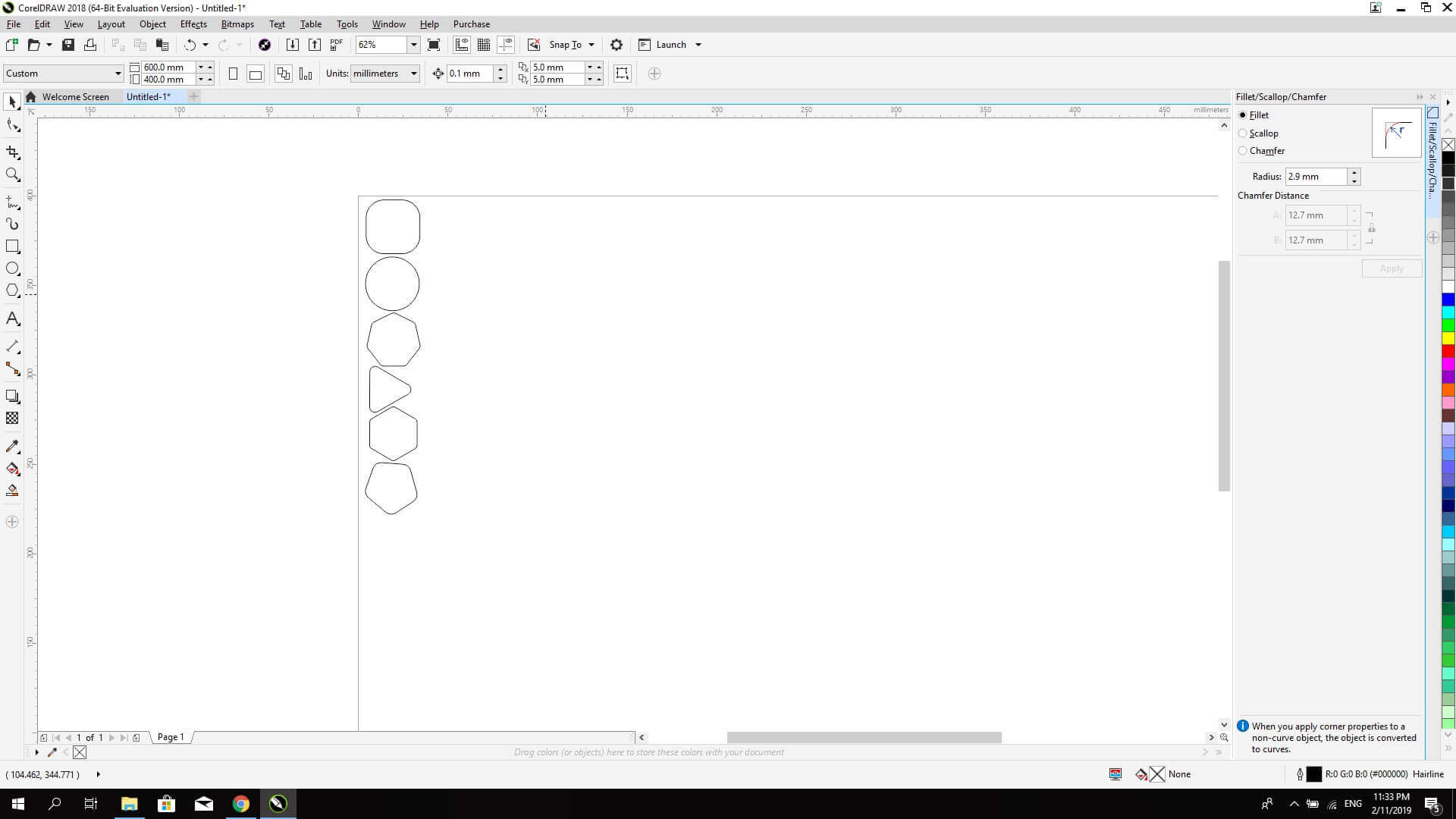

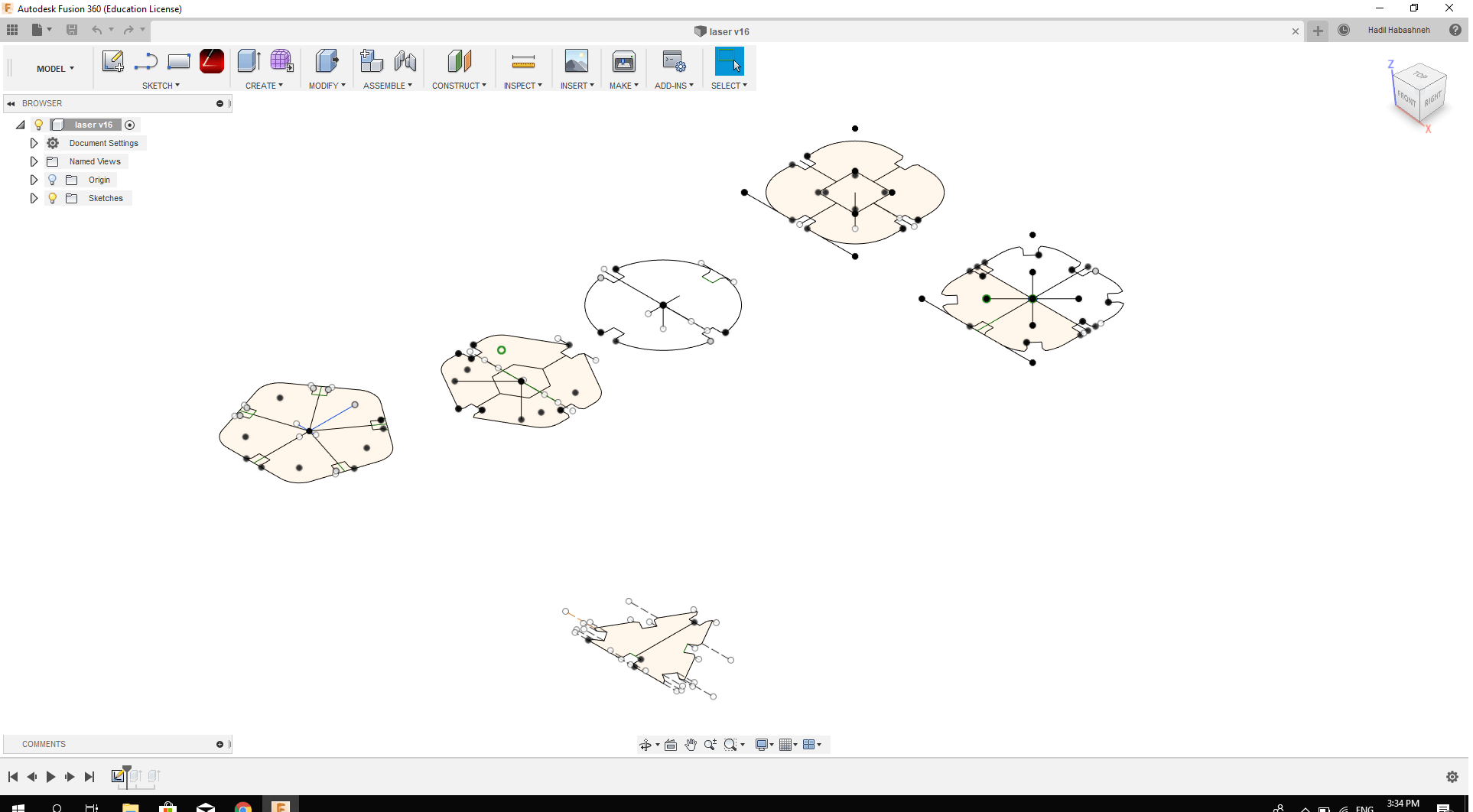

This week I designed and cut different geometric shapes with press fit joint in them. These pieces can be collected into different shapes which I will show few of them later. I used Coreldraw to design the basic shapes.

And these are the final shapes:

Then I tested the part on 3mm thick acrylic transparent sheet. I used the following settings in the first trial:

When the laser finished, the pieces we’re cut all the way through.

I repeated the cutting process again but changed the variables such as:

Again, they cut didn’t reach the bottom of the board. These are the variable of the trial that worked and gave me the results I want:

I tried to fit the pieces together and they fit perfectly and I could move on to make larger numbers.

But first I transformed to the design to parametric design by saving it as DXF file and opening it on Fusion 360, and by using the same steps as last week I sat the parameters for the joints. This didn’t work though, and so I drew the parts again on Fusion using parametric system.

Here is the

final file.