Back To Top

Week 07 - Computer aided machining

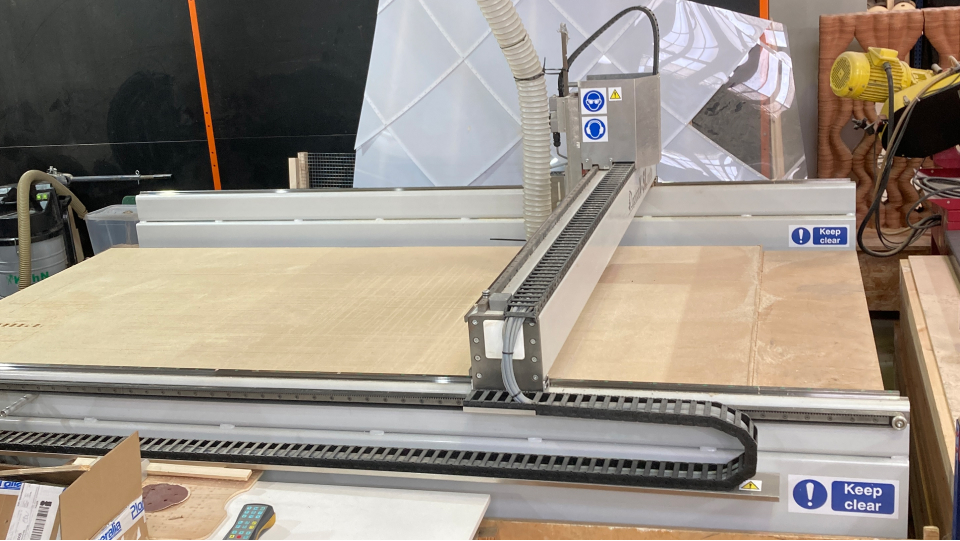

Fablab Barcelona - Raptor X-SL 3200/S20 CNC Milling Machine

Safety measures

To work with the CNC is important to be focused and take the necessary safety measures. It is important to wear protection glasses (in case loose pieces of the material fly off the machine), to use hearing protection, because the machine is actually quite noisy, also special shoes are recommendable...It's important to turn on the chips vacuum before starting. There are quite a few emergency buttons spread out in the machine and the person operating the machine should have quick access to those. Ideally, the operator is behind the operator stand controlling the machine. Also using loose clothes and hair is not recommendable.

Setting up the file for testing ...

@manu @ana @aurel @marc ... please add your thoughts!

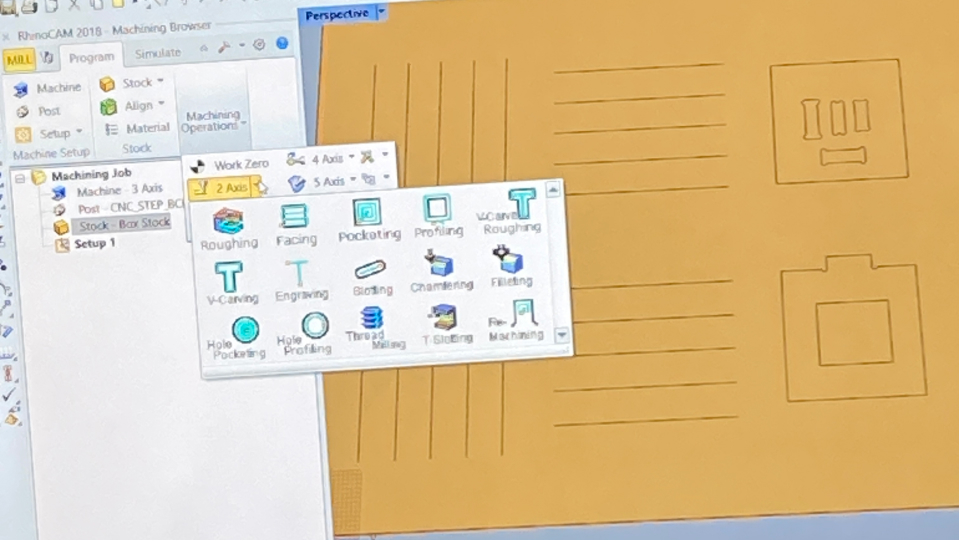

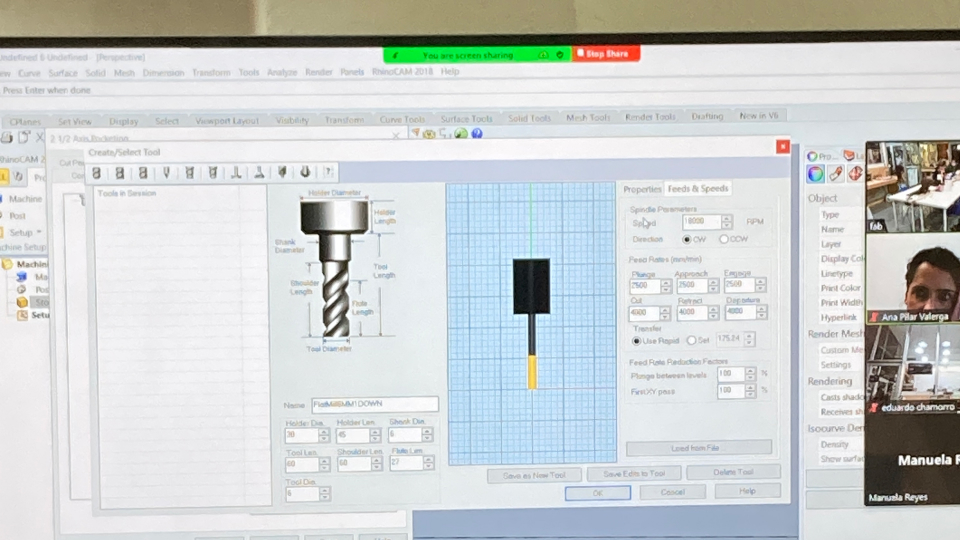

We used RhinoCAM to set up our file to test in the CNC.

In RhinoCAM we needed to define the cutting parameters. We started by defining the tool we were going to use in the CNC. It is a flat mill with 6mm diameter and 1 flute.

Our CNC machine has an aluminium bed with T-profile slots and a sacrificial layer (wood) so that when we cut we cut through it.

The sacrificial table can be made of plastic, MDF or bakelite. It provides reliable protection of the main surface, protects it from abrasion, and also protects the cutter from failure if it touches the desktop.

Also, some models are equipped with a special protection sensor to determine the thickness of the workpiece (the so–called "scale from zero to Z"). It helps to prevent errors and protect the table from damage.

Various fasteners used as the main and additional fixing tools.

Vacuum tables and vacuum devices for machine tools are also used

Types of vacuum tables:

- Simple – created in the form of a series of cells, equipped with an insulating wire.

- Point – several unrelated suction cups attached to the holes in the desktop.

- Slotted - suitable for fixing small workpieces. They are equipped with special frames that provide a high coefficient of friction and increase productivity in general.

- Latticed - are considered the most popular and multifunctional. Directly into the grooves of the grid, you need to put a seal around the perimeter of the part that needs to be processed.

- With inserts made of porous material. With such a table, even the thinnest and most fragile materials (up to the thinnest foil) can be processed. Between the pairs, you can effortlessly place the workpiece at the desired angle, it is fixed very simply and reliably.

MDF is suitable as a material.

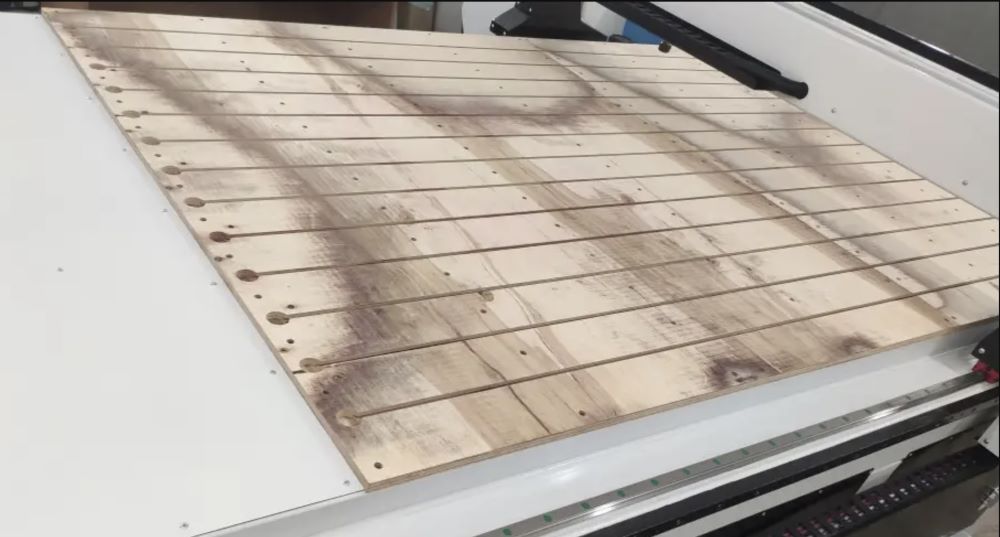

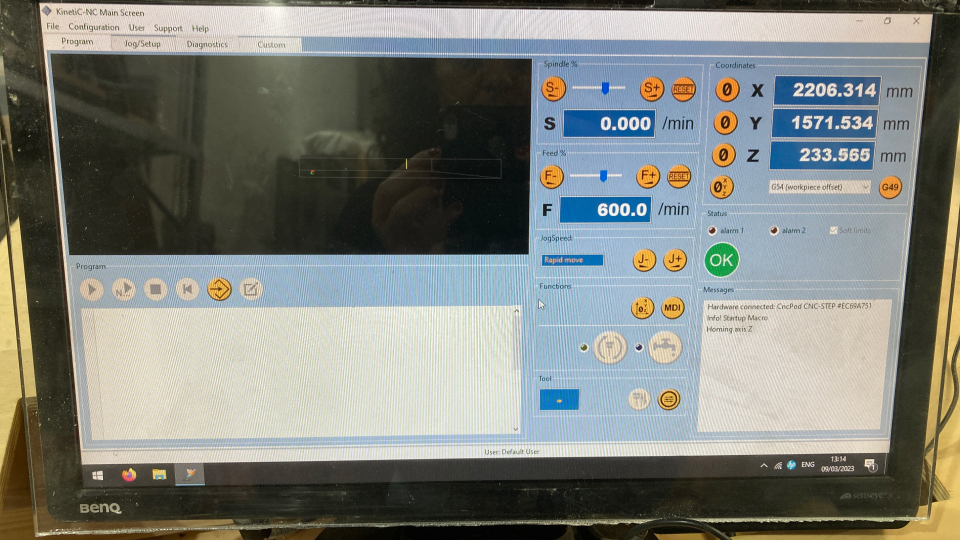

Setting up the axes. We moved the mill in x and y axis until it matches the begining of our material.

To set up the Z axis we use a piece that allow us to callibrate the Z.

Once we were ready we runned the screws file (containing just the points for the screws). Then we drill the board to the sacruficial board and we were ready to run our testing file.

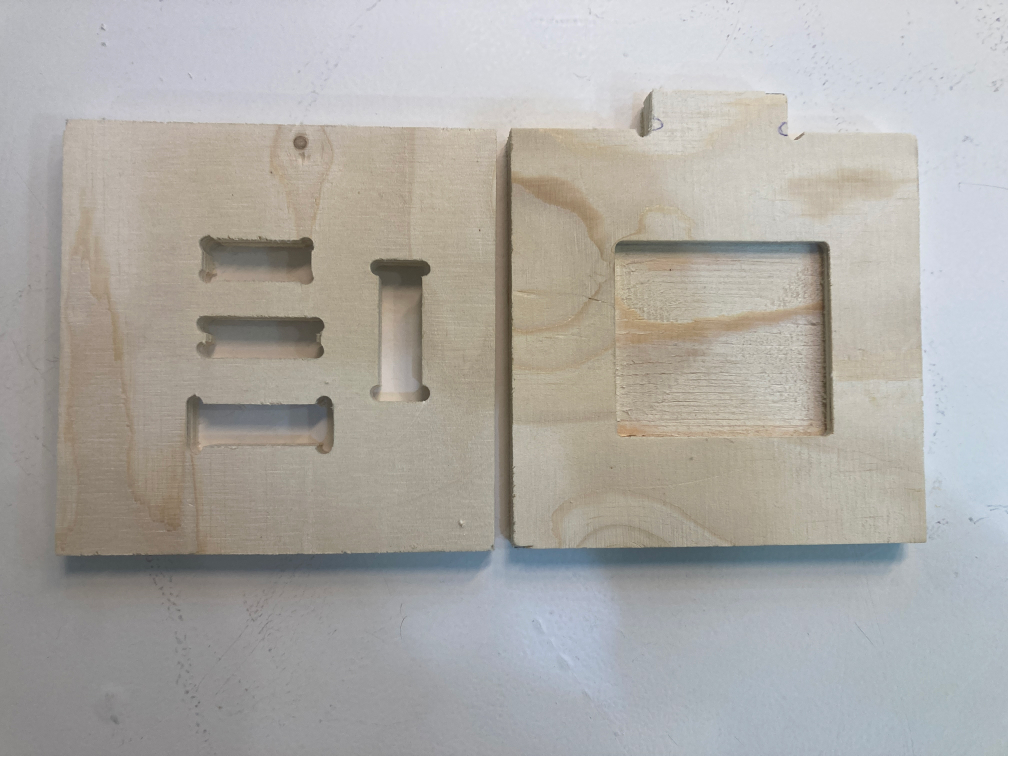

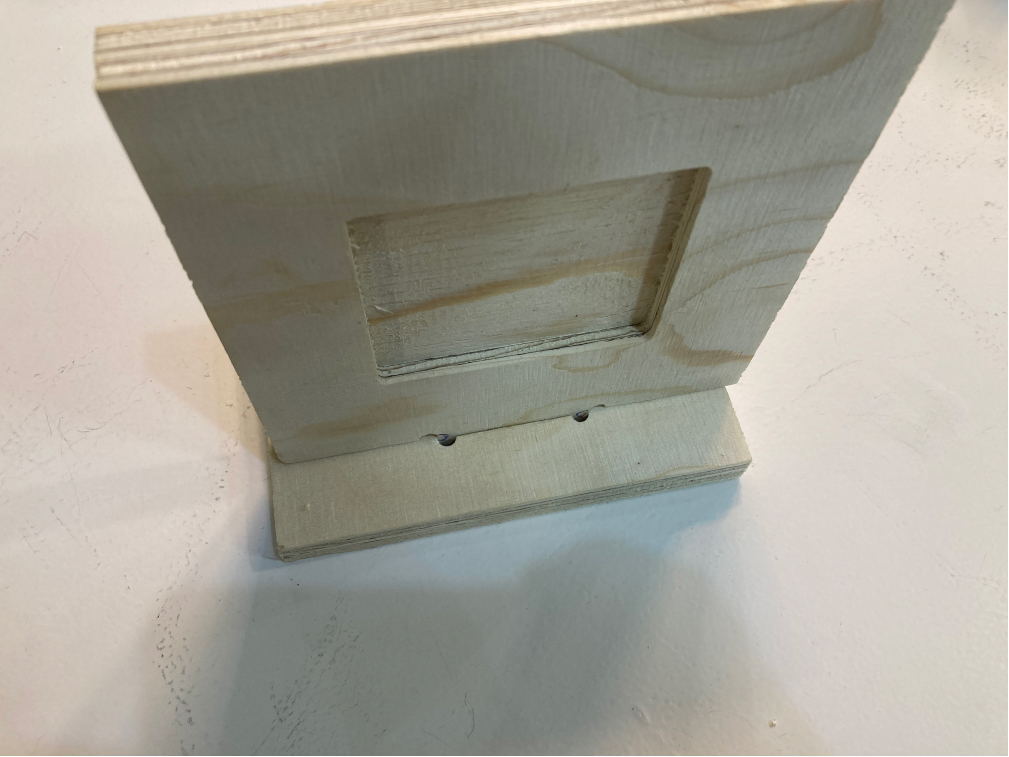

This are the results of our test.