Group Documentation: Week 14, Group 1

Molding and Casting

Review the safety data sheets for each of your molding and casting materials. Then make and compare test casts with each of them

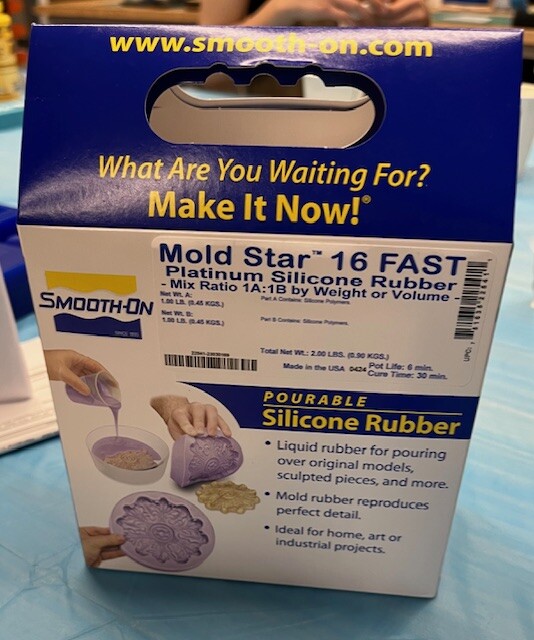

Mold Star™ 16 FAST -- our molding material

Safety data sheet hazard statements

This material is actually not hazardous and has no hazard statements. However, there are some first aid measures to follow. For inhalation, remove to fresh air. For eye contact, rinse thoroughly with plenty of water for at least 15 minutes, lifting lower and upper eyelids. Consult a physician. For skin contact. wash skin with soap and water. For ingestion, rinse mouth.

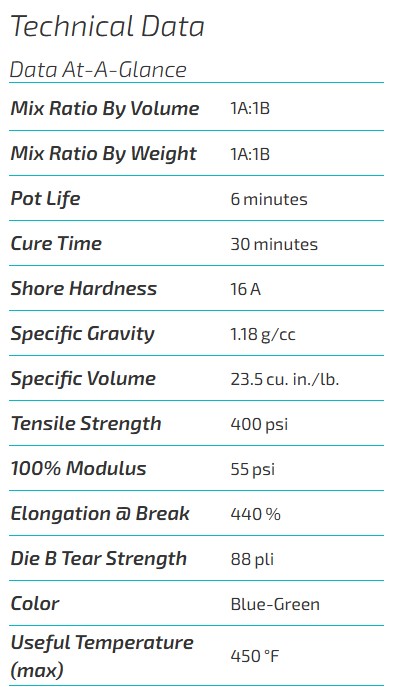

Technical data

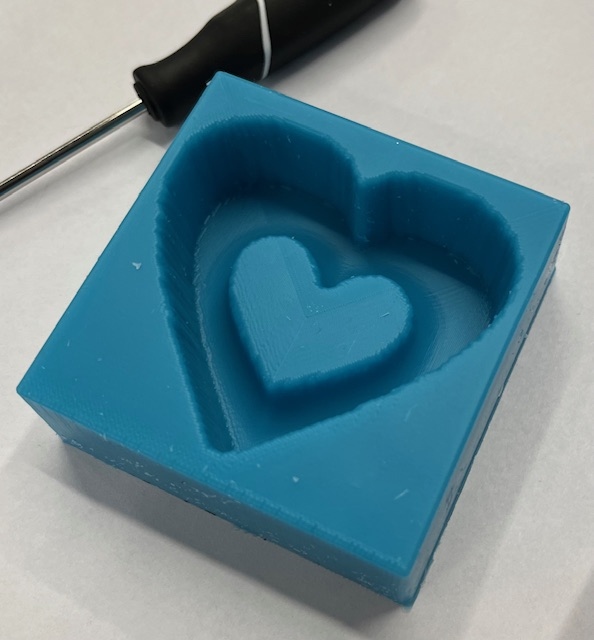

For us, relevant technical data included the fact that it is a 1A:1B mixture by weight, a pot life of 6 minutes (meaning the time you have left to create the A:B mix), and its cure time of 30 minutes (curing = time it takes mix to go from liquid to solid). The solid is blue-green.

Making a Mold

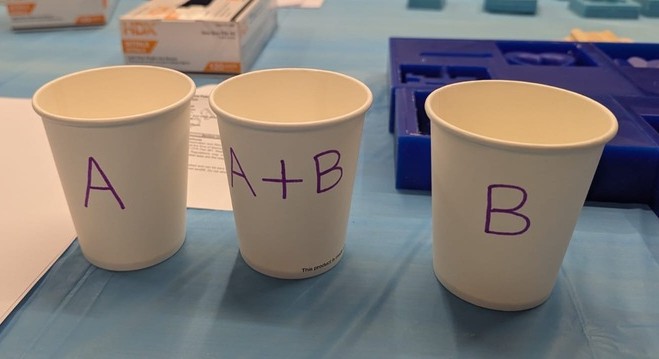

To make a mold, we started by putting an even amount by weight of parts A and B in their respective cups. We then combined them in a third cup and mixed them together for a couple of minutes. Make sure to scrape the sides of the cup when mixing the parts together.

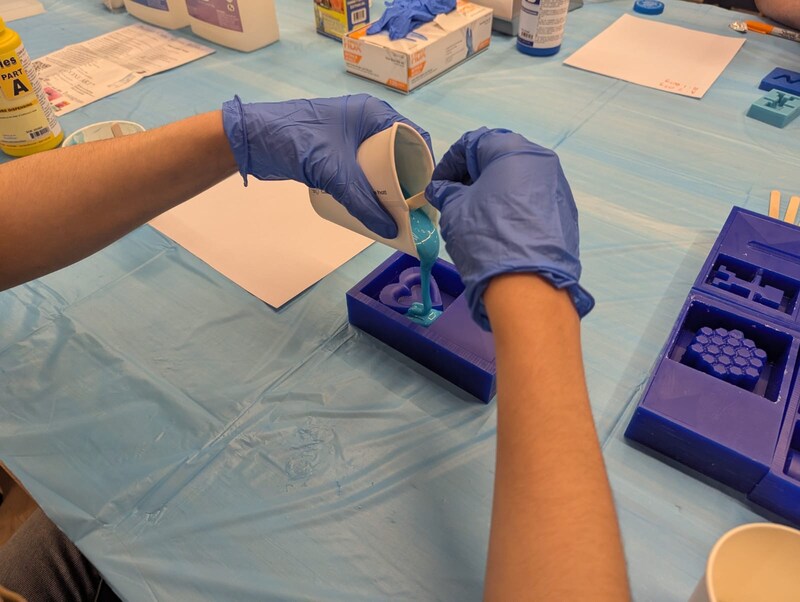

We then poured the mixture into a positive wax mold.

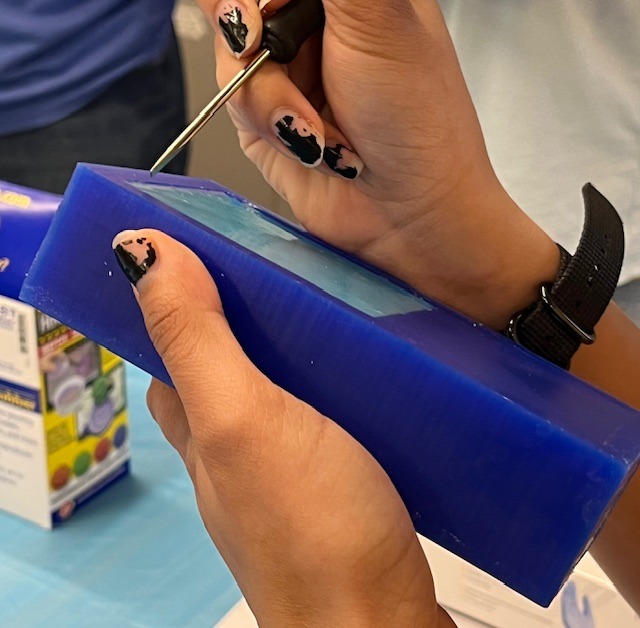

After a half hour, we used a flat screwdriver to pry the silicone mold out of the wax.

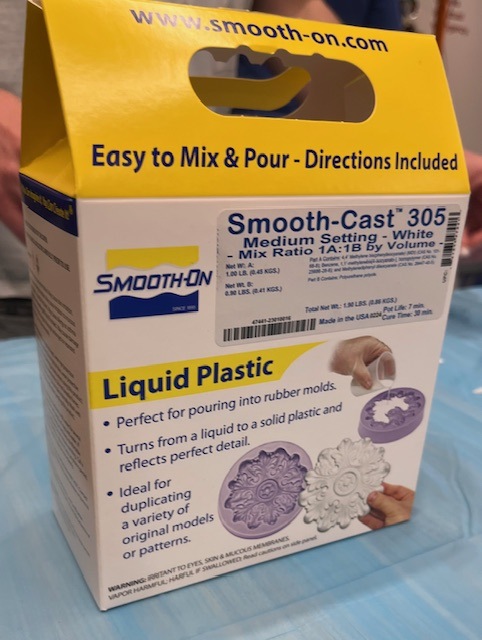

SmoothCast 305 -- our casting material

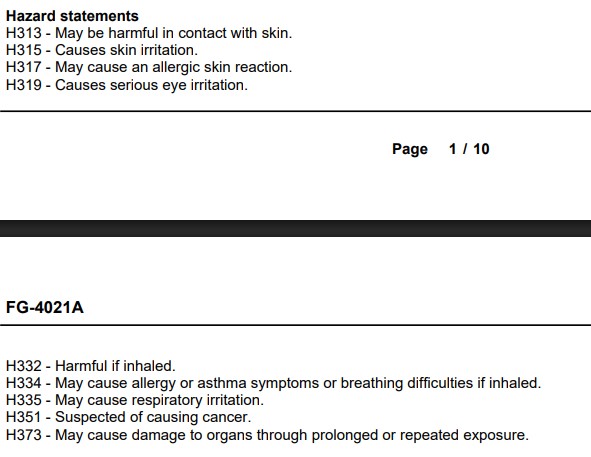

Safety data sheet hazard statements

Hazards include being a possible carcinogen, allergic reactions and skin irritation (after mixing, the material becomes very hot, so wear gloves otherwise the mixture will burn skin), respiratory symptoms if inhaled, and organ damage. Use in a well-ventilated area and ALWAYS wear gloves, otherwise the A:B mixture will burn. The material is also toxic to aquatic life, so it should not be poured down drains.

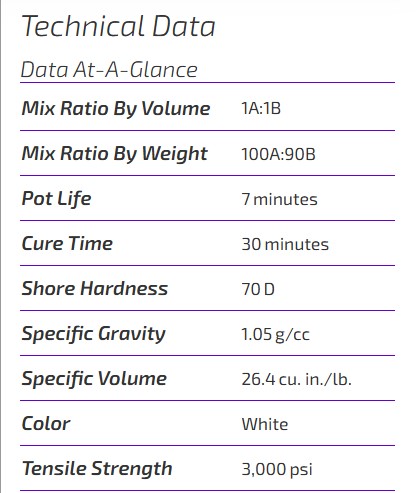

Technical data

For us, relevant technical data included the fact that it is a 100A:90B mixture by weight, a pot life of 7 minutes (meaning the time you have left to create the A:B mix), and its cure time of 30 minutes (curing = time it takes mix to go from liquid to solid). The solid is white.

Casting

The process for casting was about the same as for making the mold. The ratio of A to B is 10:9 by weight. We used some pre-made silicone molds for making the casts.