Group Documentation: Week 5, group 1 (Tammi, Gillian, Hanna, Sierra S.)

3D Printing Design Rules

Gillian Cote -- Supports: overhang, clearance

Overhang

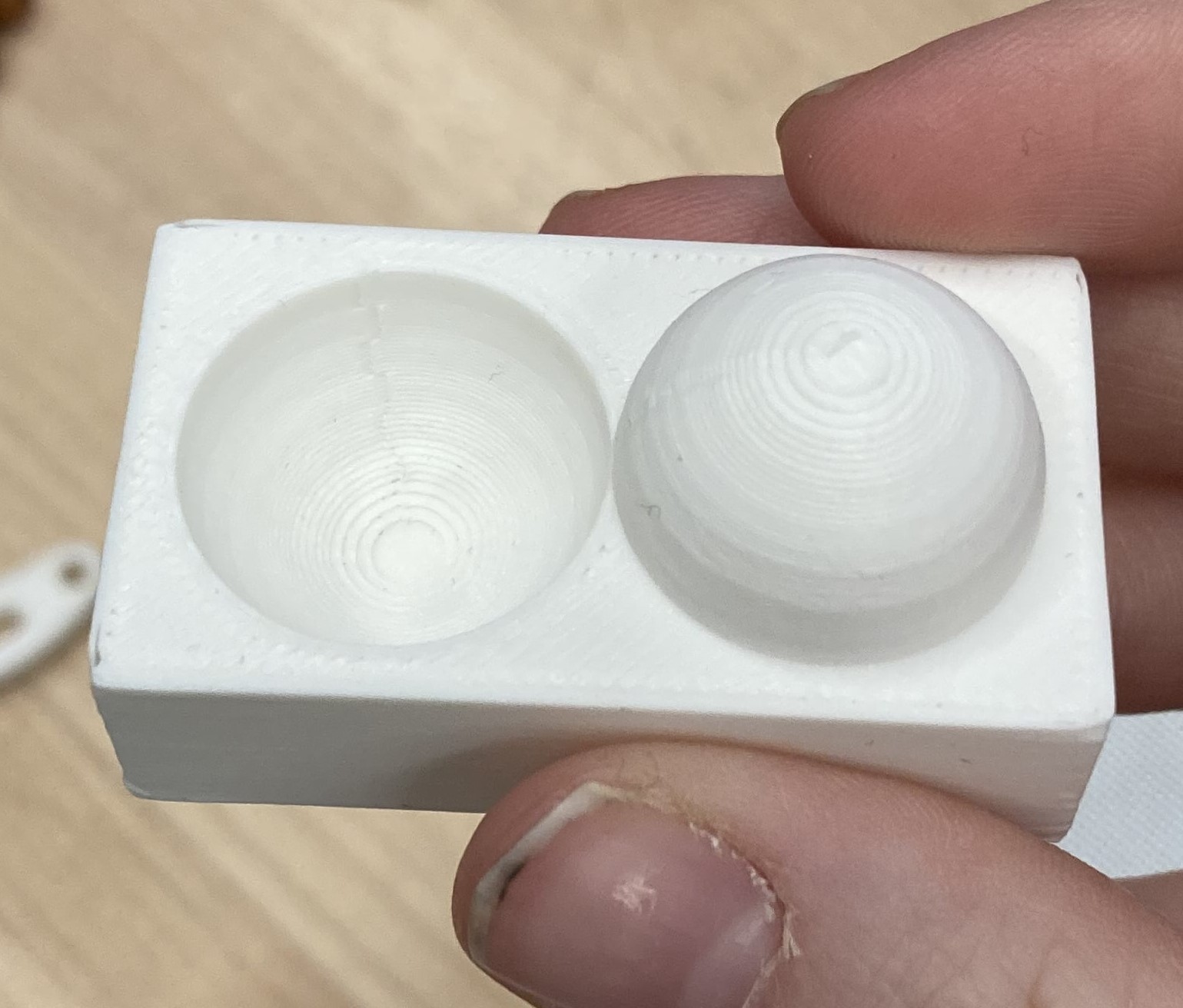

Overhang is when the model goes outwards from the previous layer and tries to print on nothing. Supports are excess printed pieces to support the overhang that can then be broken off once the print is complete. The above circles were printed vertically to show what happens with and without supports. The one on the right is printed with organic supports, which is often easier to remove. The one in the middle is grid supports, which can be a bit harder to remove in more detailed prints. The one on the left was printed without supports and you can see the stringing at the top of the circle where it was trying to print on nothing.

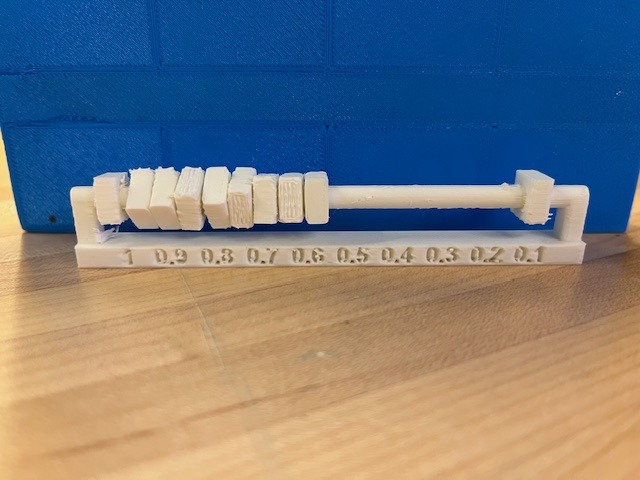

Clearance

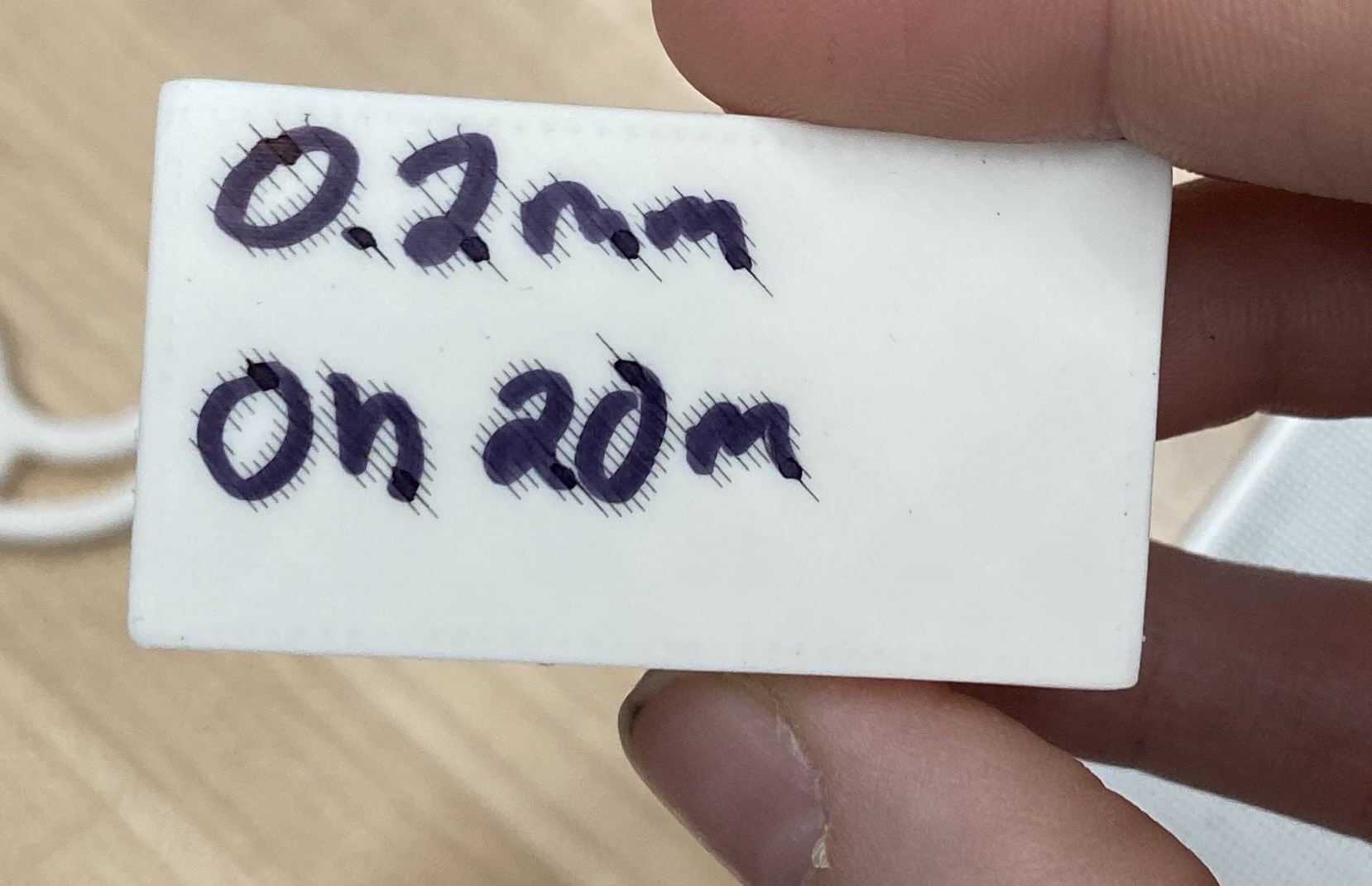

The clearance of the printer describes how close two objects can be printed together without fusing. The image above has a bunch of squares that have a gap between 1 mm to 0.1 mm between it and the rod. Our printers have a clearance of 0.2 mm, because all of the squares with a gap of 0.2 mm and above were able to move on the rod. The 0.1 mm gap just fused to the rod.

Hanna Ondrasek -- surface finish, infill, tapers

Surface Finish

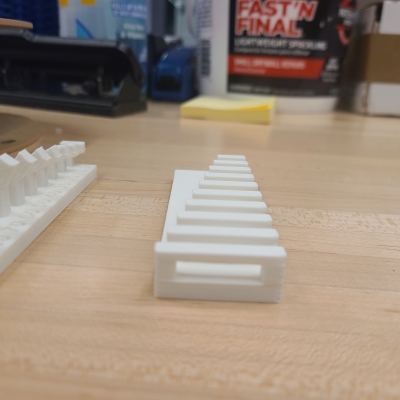

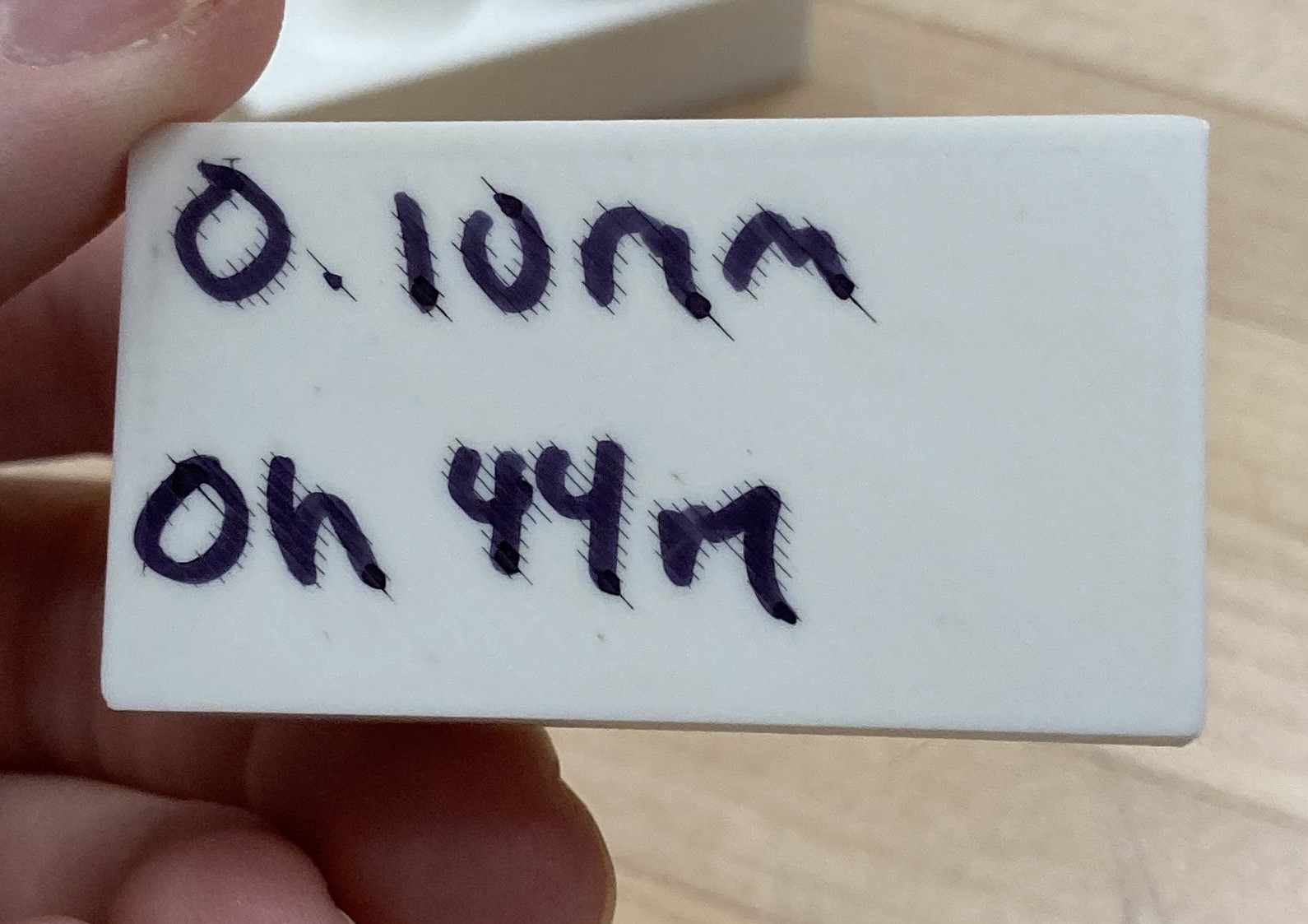

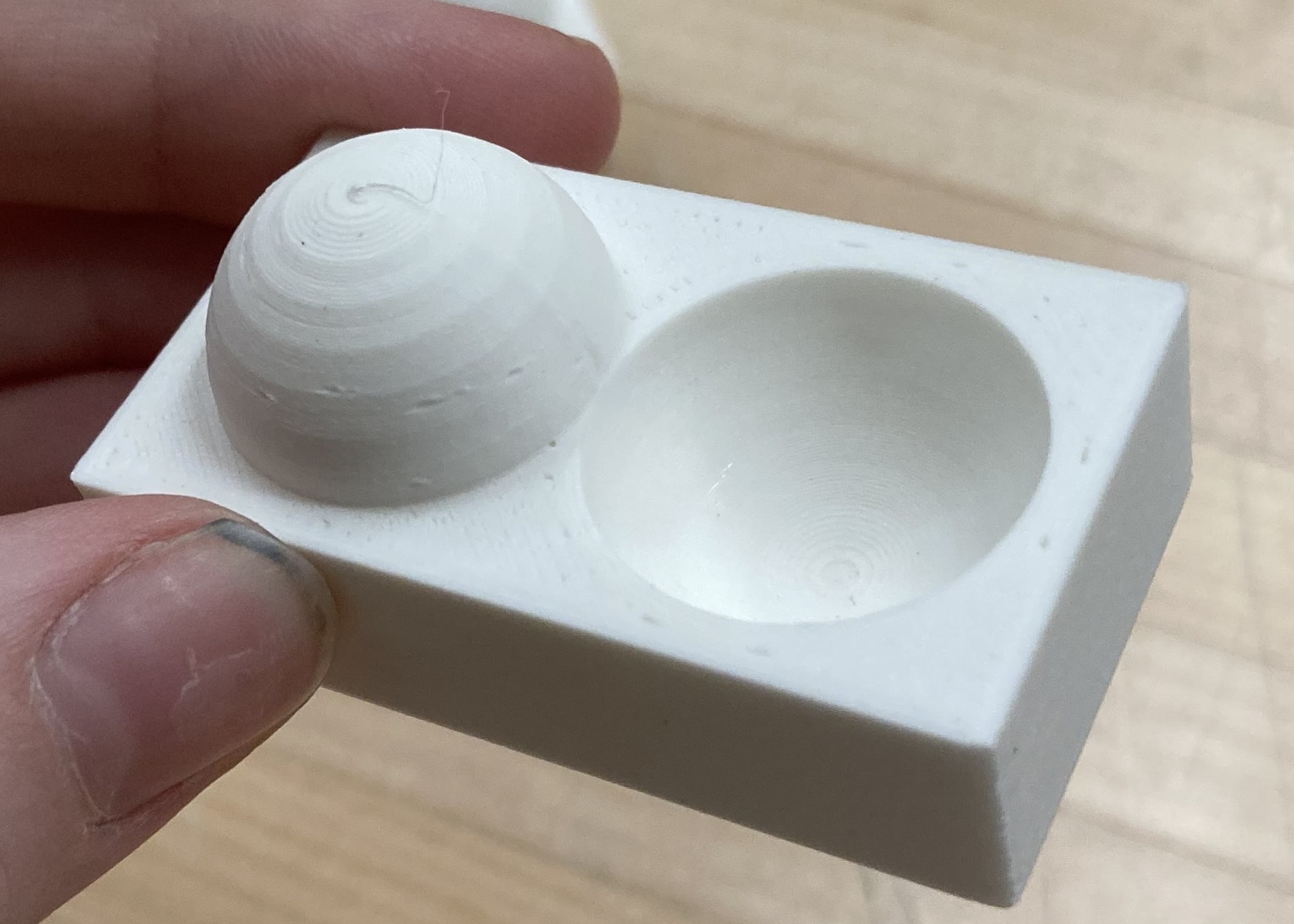

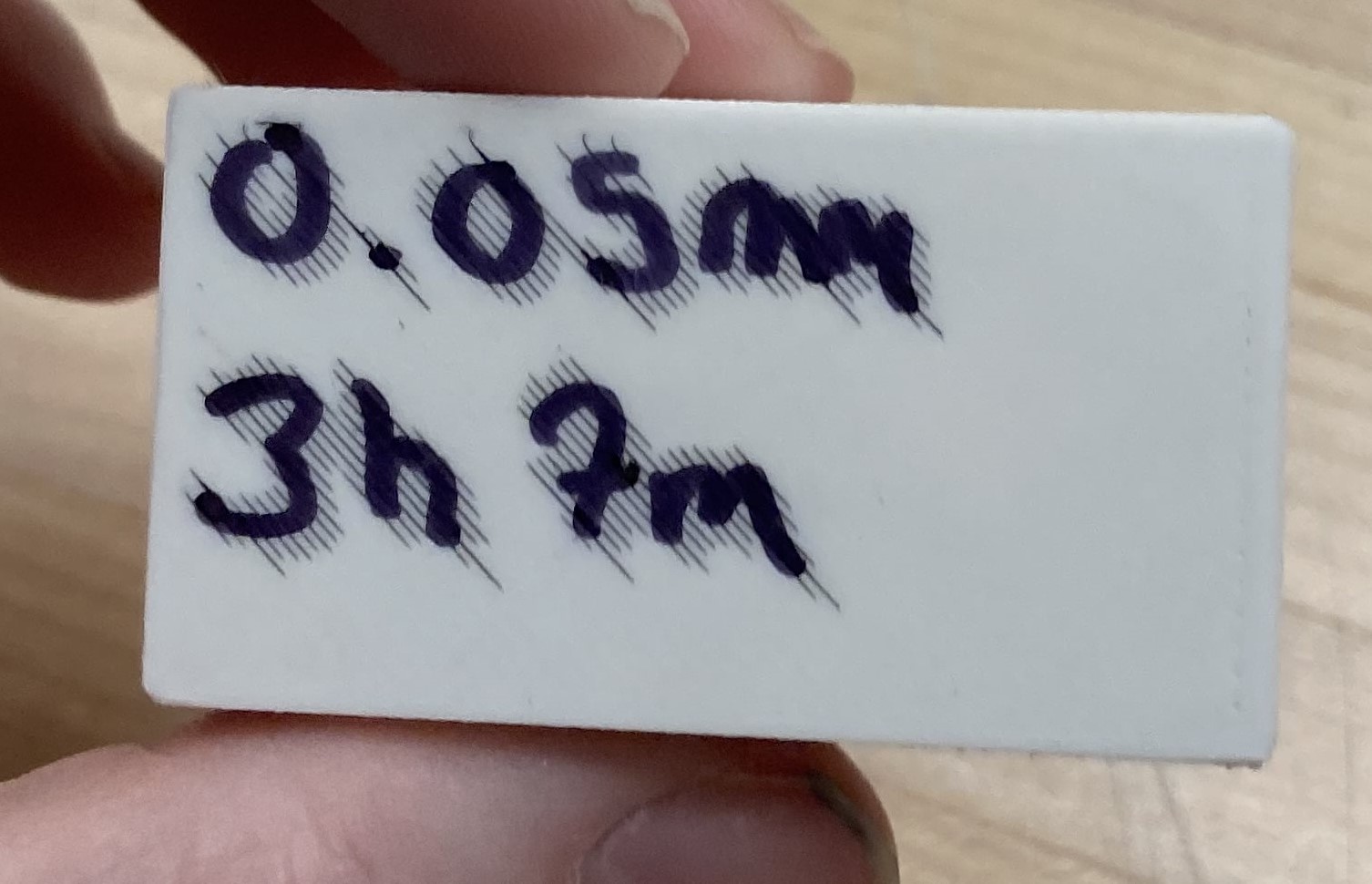

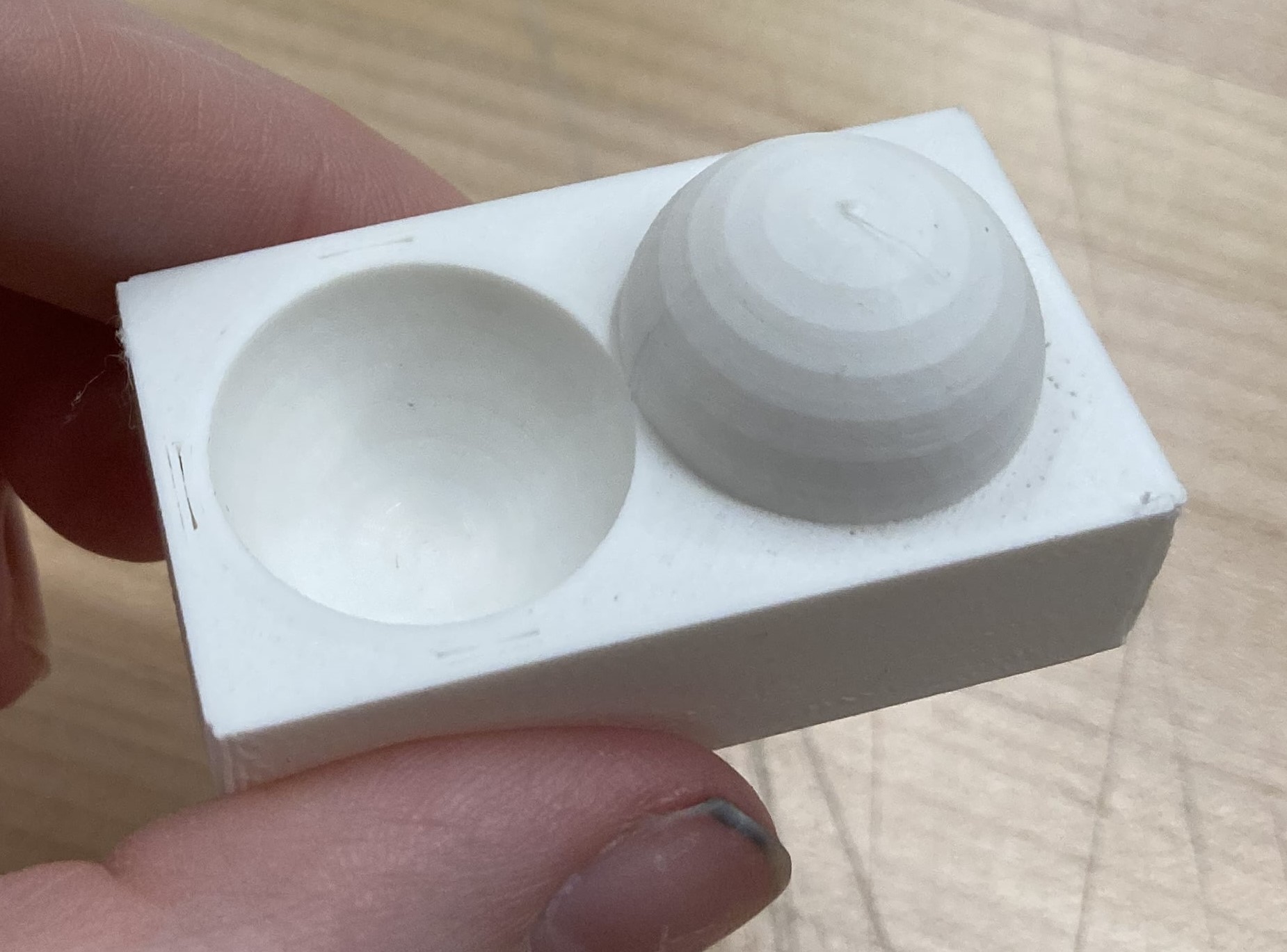

Surface finish is a measure of how smooth a 3D print is. A greater millimeter surface finish will result in a print that is "rougher" in appearance. The lines of the filament appear to be more defined, as shown in the series of images below.

The final print, which took 3 hours and 7 minutes, is a great example of diminishing returns in terms of surface finish. The difference between this print and the 44 minute print are not noticeable, unless you were to get very close.

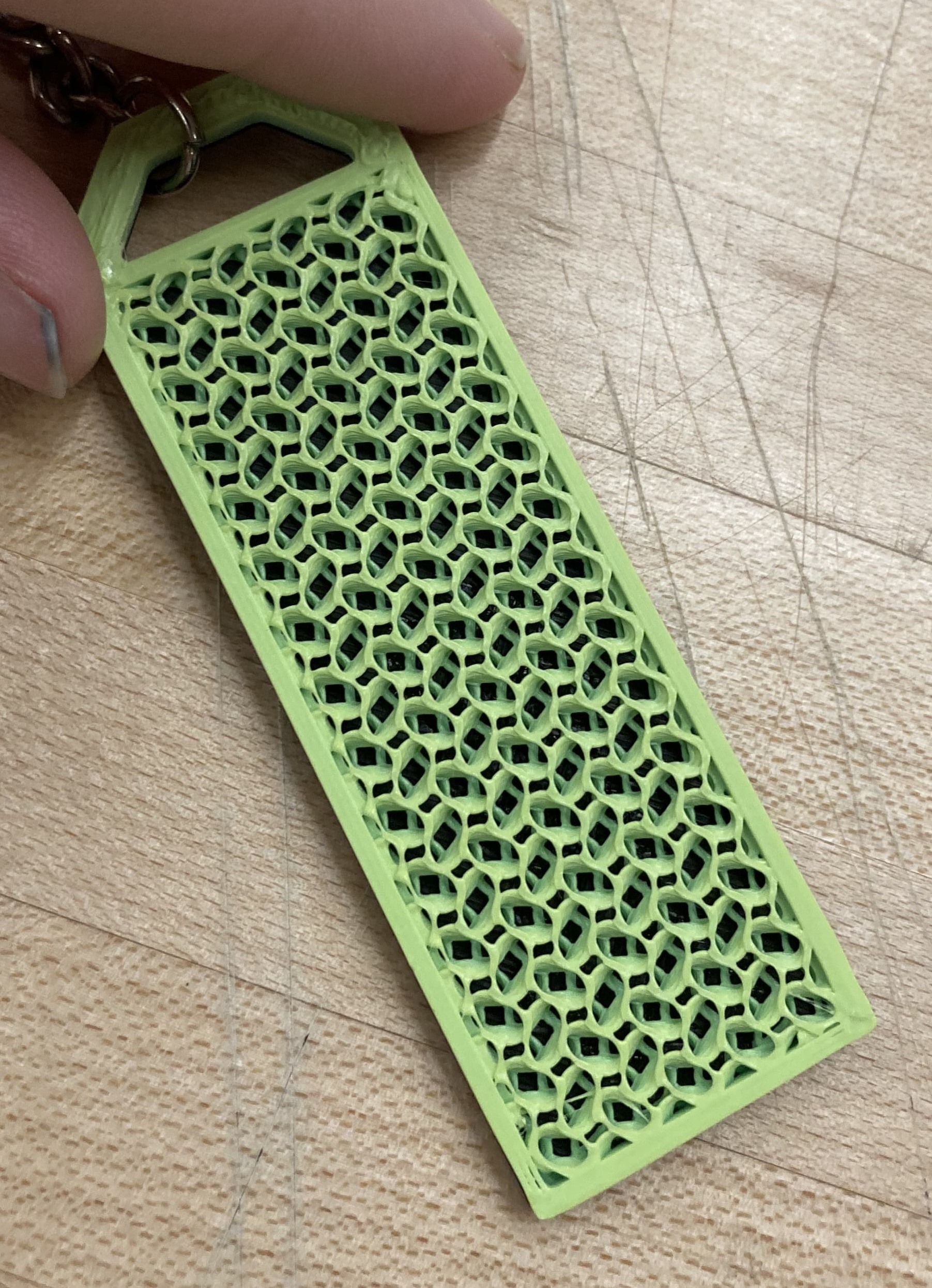

Infill

Infill is a structure that fills in the inside of a print, providing stability and strength. It acts as a support network that is customizable depending on the desired weight and strength of a print. Without infill, there could be warping and sagging of the print. There are numerous types of infill, but the two of the most common are grid and gyroid. In Wheaton's fab lab, we typically use gyroid infill because of its superior load-bearing capabilities.

Below is an example of a corrupted infill:

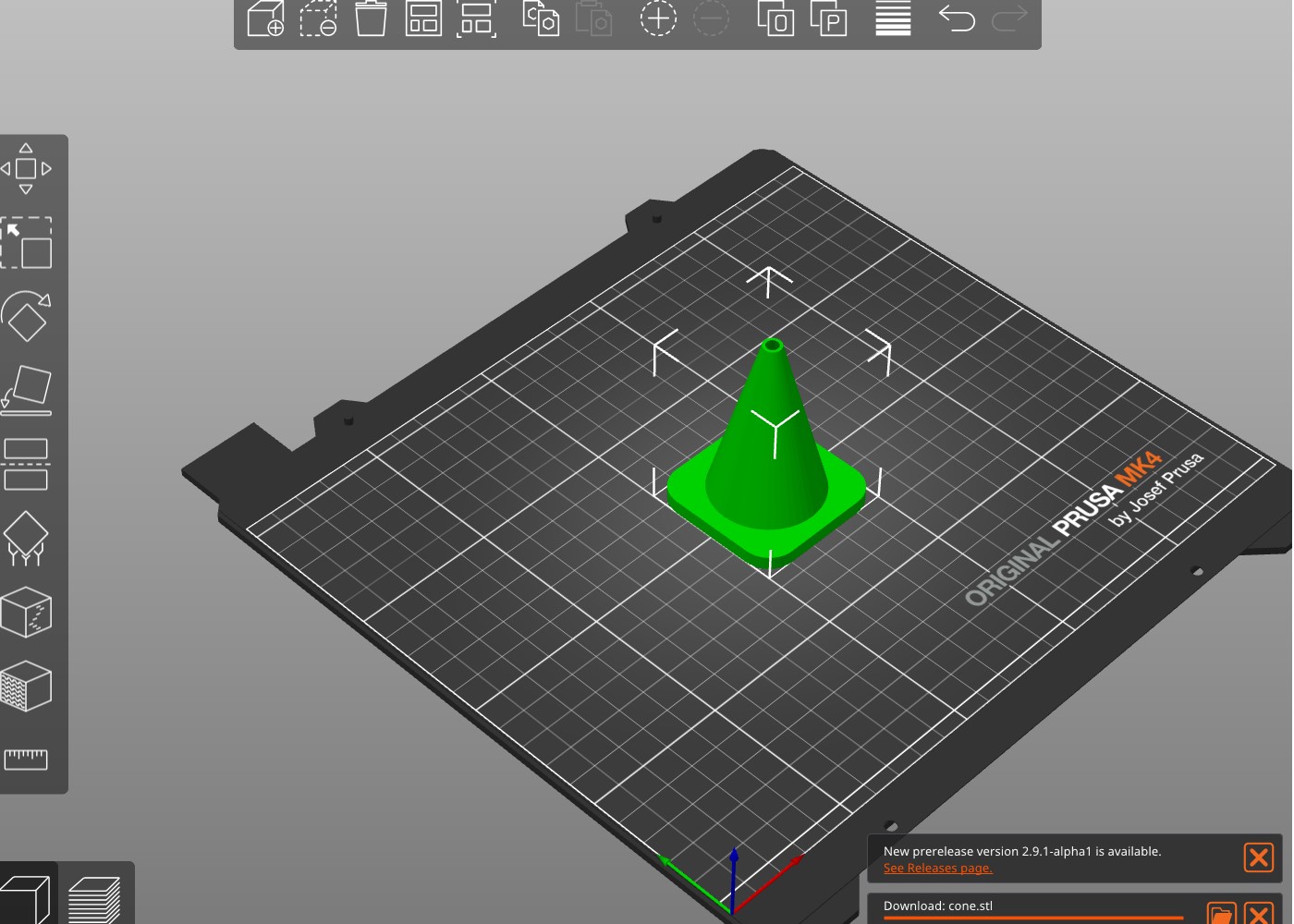

Tapers

Tapers refer to the widening or narrowing of a feature of a print. One part of the print is wider than another, such as in the case of a pyramid shape. Making a cone in fusion 360 and printing it is an example of an object that tapers. The top of the traffic cone below is a taper.

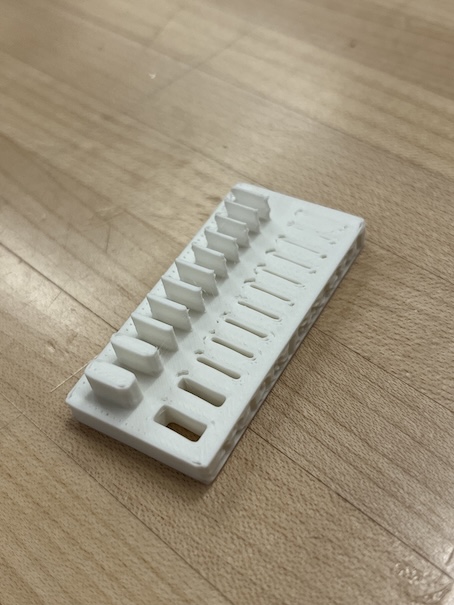

Sierra Seetin -- wall thickness, dimension, anisotropy

Wall Thickness

Wall thicnkess is the distance between the inside and outside surfaces of the printed object. As the 3D printer we use (Prusa Slicer MK4) has a nozzle size of .4mm, that means the thickness of any wall in the print must greater or equal to .4mm. On the sample print, the walls with a labelled wall thickness of .3mm, .2mm and .1mm were actually measured to be .4mm.

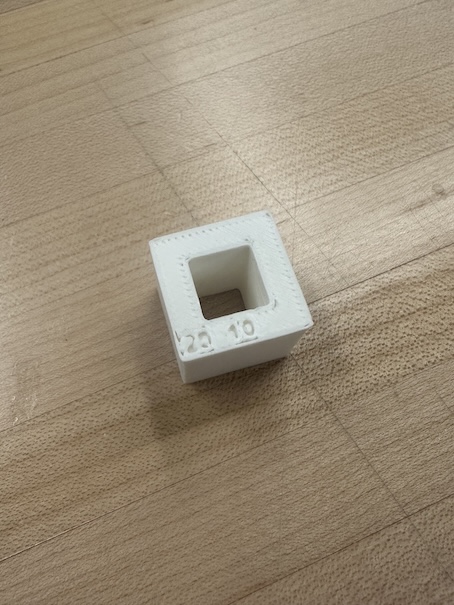

Dimension

Dimensions refer to the height, width, and depth of a model, also known as the X, Y and X axes.

Anisotrophy

Anisotropy means a material’s properties change depending on the direction. For example, a print will be much stronger if printed horizontally. A print looses integrity as it print vertically, or on the Z axis.

Tammi Redd -- angle, overhang, bridging

Angle

The steeper the angle the less smooth the underside of the overhang will be if it doesn not have supports. At 90 degrees there is no problem at all but the clumping begins around 30 degrees and by 0 to 10 degrees the bottom of the overhangs seem to become more damaged. Steeper than 45 degrees will require additional supports in order to print successfully. Otherwise, each additional layer that is added will not have sufficient support.

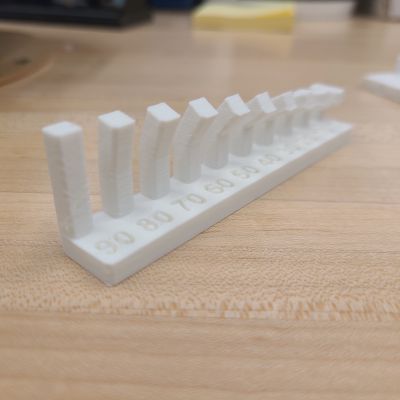

Overhang

In 3D printing there is a a guideline that states overhangs should be less than 45 degrees. Overhangs that are steeper than 45 degrees require supports. The printer can do upto 70 degree overhangs. At 45 degrees each new layer is in 50% contact with the layer below it. Both overhang and angle are demonstrated in the picture below.

Bridging

Term for printing layers over thin air without the use of supports. Our printer seems to created bridges upto 20 mm without any problem at all. Short bridges made out of thin layers can suspend material into the air while lengthier bridges require appropriate supports. On most 3D printers the angle of the bridging infill can be adjusted but most importantly on the MK4 we can print at a lower speed, lower flow, and lower temperature in an effort to avoid bowing or drooping.