.png)

Hi! Welcome to Week 15

This week’s assignment was to design a machine that includes mechanism+actuation+automation, build the mechanical parts and operate it manually as a group.

.png)

This week’s assignment was to design a machine that includes mechanism+actuation+automation, build the mechanical parts and operate it manually as a group.

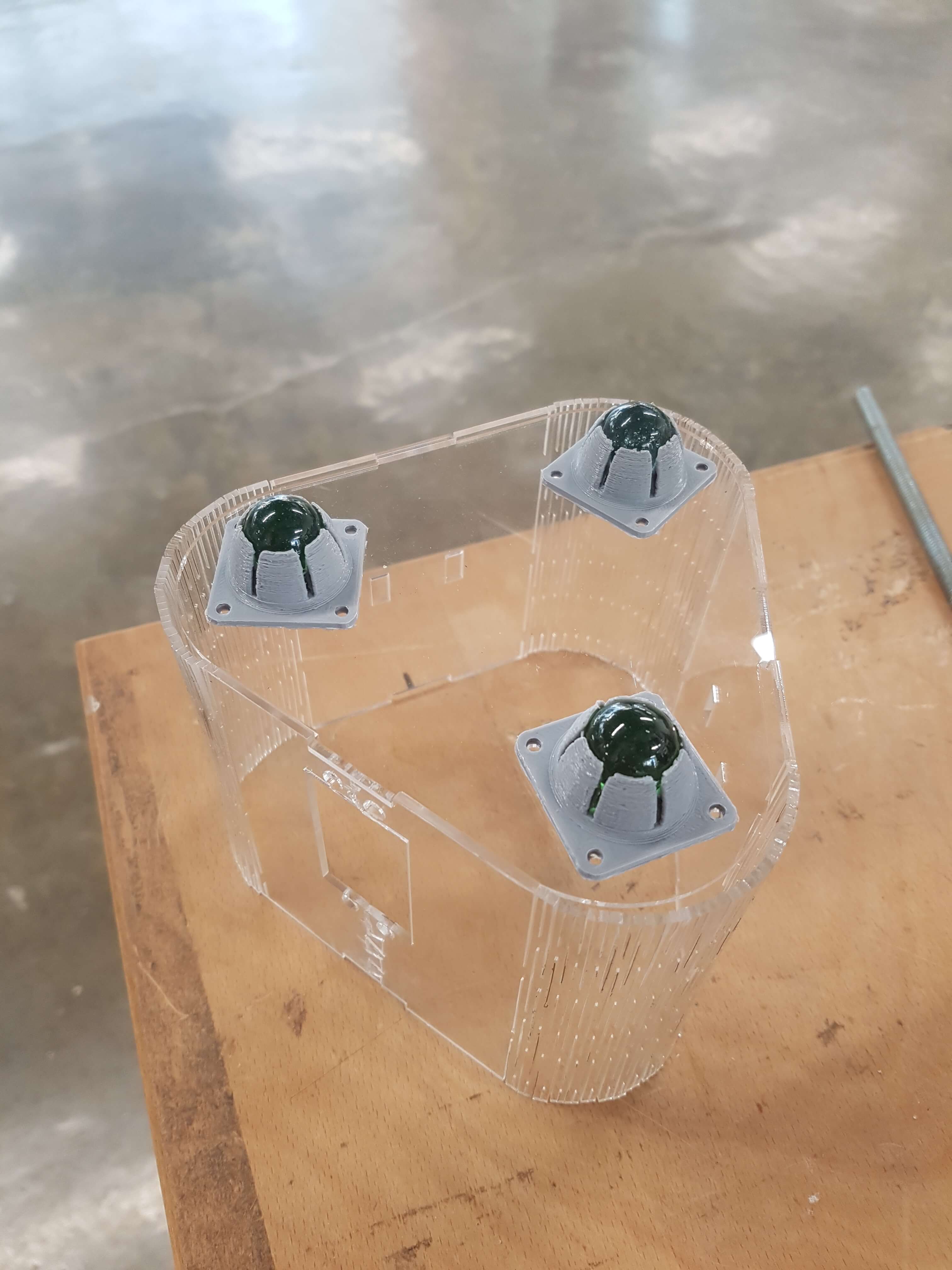

This week, my colleagues and I decided to build a machine that can draw on the wall. We divided the tasks between us and I had the task of designing the center piece that will hold the pins and servo motor. My colleague Tarek had already designed the marble balls holders, which will be used to make the piece's movement smoother against the wall, and my colleague Ahmad designed the pins' holder which will rotate to change pens.

I started my designing process by checking the machines available online for the same purposes. I tried to understand the components and arrangements, and the value of each component in the design. After I had a clearer understanding, I started designing process on Fusion360. The first design I made had few points that could have been enhanced for an optimum design, which are:

* Increasing the distance between the ball holders, placing them closer to the corners than the center.

* Cutting the depth of the machine to the smallest depth possible to take advantage of inertia.

so, what I did is I went back to the design, increased the distance between the ball holders, and made the size of the tail smaller, this is the final design

Now that it was ready and the whole team agreed to it, I made the 2D plans on CorelDraw, and then made them using laser cutting.

Next, I designed the belt clips, again using fusion 360, it’s a simple design of a small cylinder with belt shaped cuts in it. This is how it looked:

And I 3d printed the pieces, and then tested them with the belt. It was a tight fit, which means it would hold the machine in place.

Download the Body file.

Download the Clip-STL file.

Download the Clip-original file.