Sixth assignment

20 February 2019

Part I

Test the design rules for your 3D printer

Part II

Design and 3D print an object

3D scan an object

Part II

This is the individual assignment: - design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively.

You can check the group assignment for this week in the previous page.

3d model and print

Trying new features

My 3d design can not be made subtractively, this is because of the angles that it has. Even though the external part may be possible with a 5 axis cnc machine the internal angles are still impossible to make because of the angle.

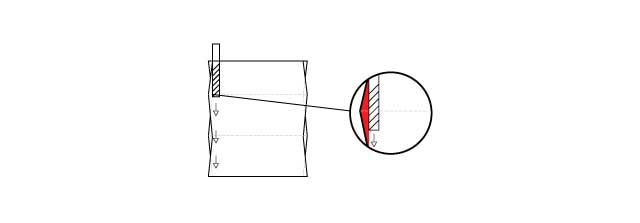

In the next image I show how the cutting tool goes down but is no able to make the angle of the model. The red part is the part that is not machinable. In a 3 axis machine, neither the internal nor the external surface angles are possible to machine.

Also, there is the possibility to create almost any shape with serial planes using laser cut, but the esthetic and functionality changes completely, even in the fabrication process, where you need to assemble or even stick each plane with some glue.

3D Modelling

I used Rhinoceros to model this vase.

For this object I didn't need to model the internal walls as I was going to use a feature from the Z-suite.

I wanted to tried different options that can be made with the software, I find it interesting that there is a lot more than you think that can be made from the software, this helps saving time because you can just choose some features instead of modeling everything in 3d.

As in the previous exercise I used a Zortrax M200 Printer, and the Z-suite slicer. For more detail you can check Part I of this assignment.

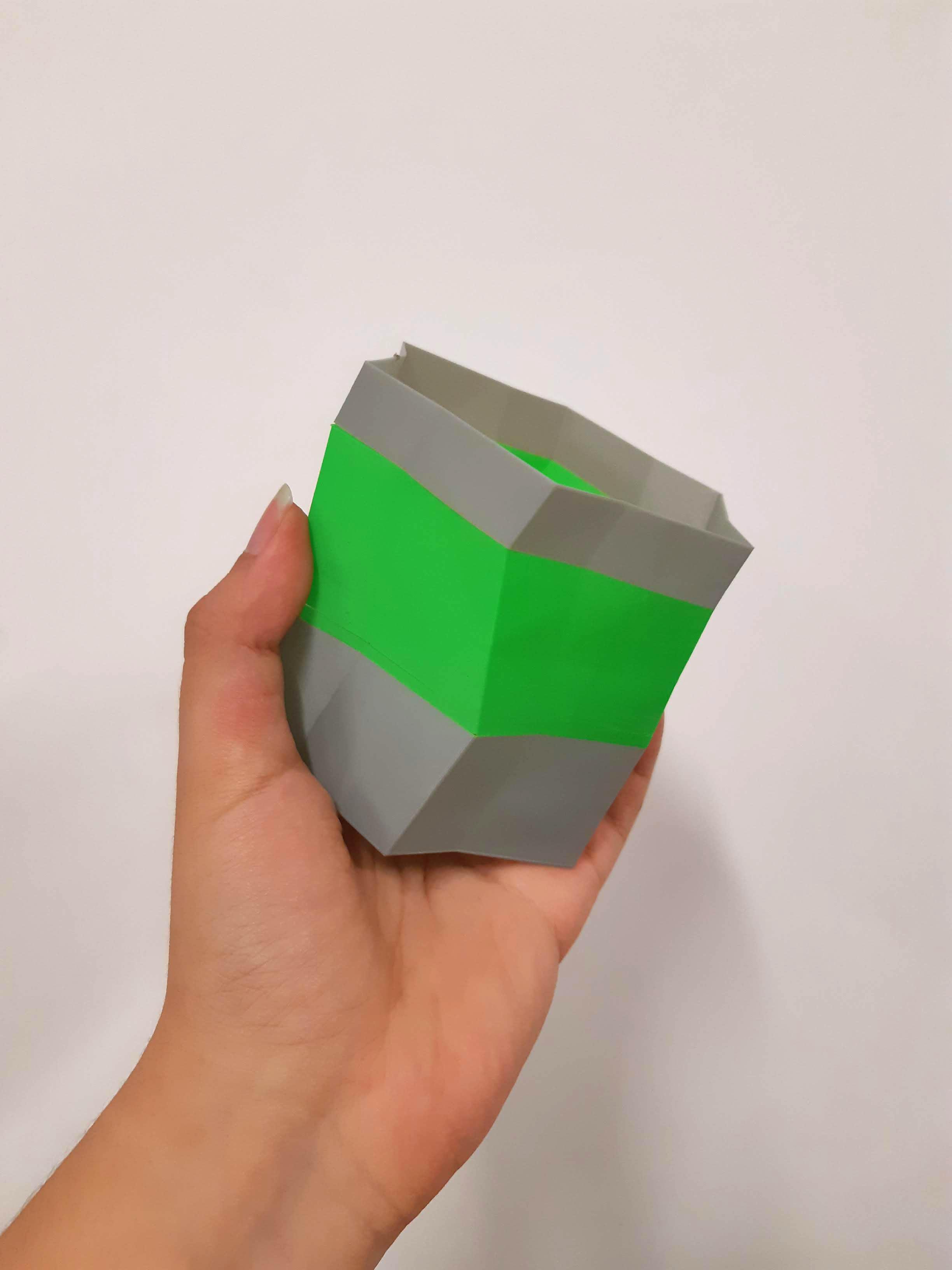

I selected the shell option, with this the print consist of a thin contour wall and you can choose to print the bottom and/or the top part. As the nozzle makes one pass for each layer the printing time is reduced a lot allowing us to print bigger things in less time.

I used the pause feature in the slicer to make a filament change and make a two color print.

3D scanning

what is it?

It is a technique used to capture the shape and occasionally the color of an object, a person, or and environment. The result is a 3D file of the object which can be saved, edited, and even 3D printed

The advantages and limitations for 3D scanning depends on the technology used for it, different scanners rely on different physical principles, but I am going to mention a few general ones.

Advantages

accuracy

3D scanning results are pretty accurate, it has enable for this technology to enter in different industries and sometimes become essential. It helps with documentation, investigation and reconstruction in different fields such as: MEdical, Paleontology, Archeology, Architecture, Civil engineering, Art, Entertainment, Law enforcement.

Limitations

Multiple shots

Most times one shot is not enough to collect all information needed, it is usually required to make some repetitions, even hundreds depending on what is the object being scanned and then the information collected need to be integrated in a process called alignment and then merged to create a complete 3D model.

Post edition

Even if we don't make multiple shots post edition of the 3D file is required, it might be something extra we need to get out or some spaces that the scanner didn't read and we need to fill.

getting it to work

For this part I tried with two different scanners. Each scanner has it's own trick.

I had my classmates helping me for this part, as they were practicing for this part of the assignment too. We started with the SENSE scanner, but we had a lot of trouble making it work the software was showing lost of tracking so many times to count.

We thought the issue was changing the distance from the target (me) when moving around it. So I got on a rotating platform, in this way the distance would be the same along the scan process.

But still, it didn't work so we decided to give it a shot with the KINECT

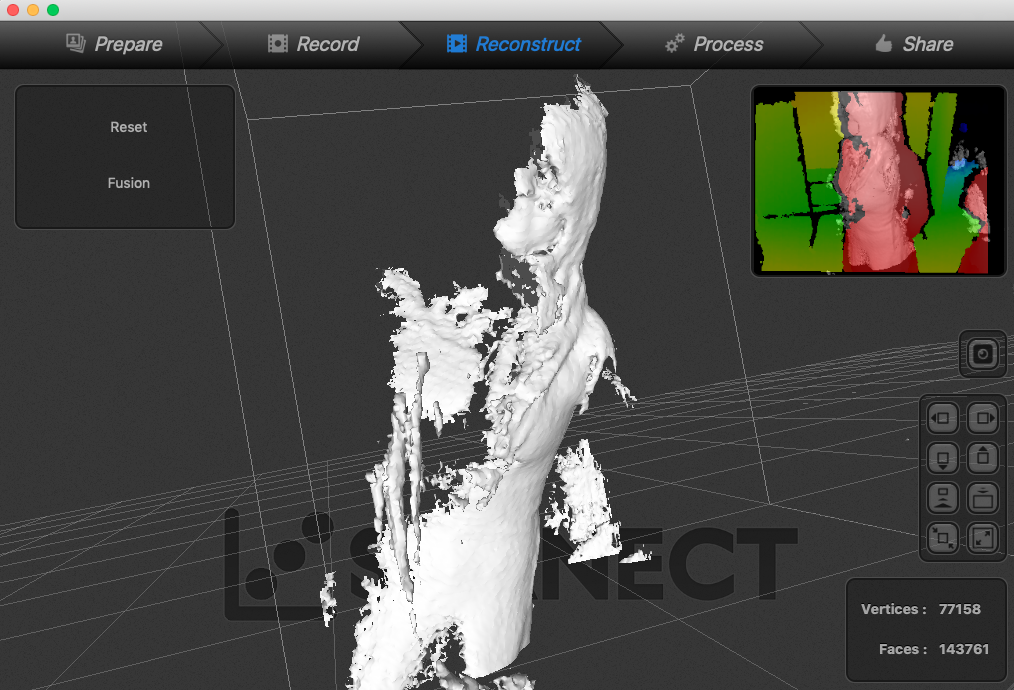

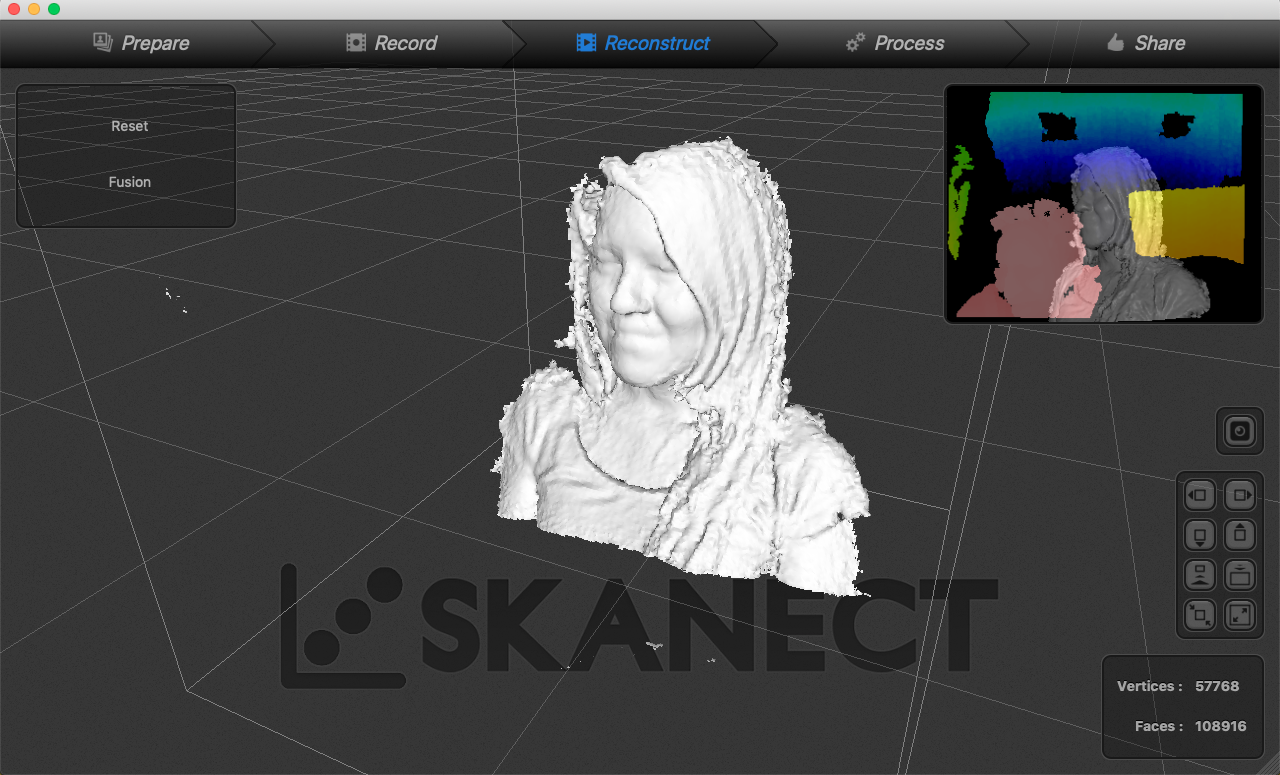

This time, with this device, it worked a lot better. A friend of mine was holding the Kinect while I was turning in the platform, it also went out of target a few times but the software change the silhouette to red, and you can fix it returning to the position it lost track, it changes colors again so you would know when it's time to continue the scanning.

This is my second attempt it turned out pretty well.

Unfortunately I lost the 3d files and although I have the screenshots I wanted to go a little further from here so I tried again a few days later.

This time I started again with the Sense scanner and the rotating platform, but after a while this device worked better without it. The best way to do it was moving around what you want to scan, very carefully. As the target was, once again, me, I got some helpers moving around me with the scanner and the with the laptop to which it was connected.

Finally I used Meshmixer to repair the file and this is how it turned out.

DOWNLOAD

Part I

Test the design rules for your 3D printer

Part II

Design and 3D print an object

3D scan an object