This week is one of the important component of E textiles and its tough for many. I like electronics and after Fab academy I had good learning experience with various projects involving electronic production. I am curious to work on this. But as we dont have many components like conductive ink, thread, hook etc in India, so we procured few things before Fabricademy started and few in the middle. So we would have some limitation in this week. Lizastark, is one of the best presenters I have come across to explain electronics from basics and specially introducing novice like us to E textiles. Though it all looked simple to do but its not an easy week for me but the end I started to enjoy these.

This week's lecture introduced to an overview of the field of electronic textiles, examples in the field as well as materials and technical development. This weekI designed an Tilt sensor as Digital sensor and LDR with Vibration motor as Analog using Arduino UNO.

"Anything can happen in this week"

Nishtha Kaushik

Steps and Processes

Introduction to Digital and Analog

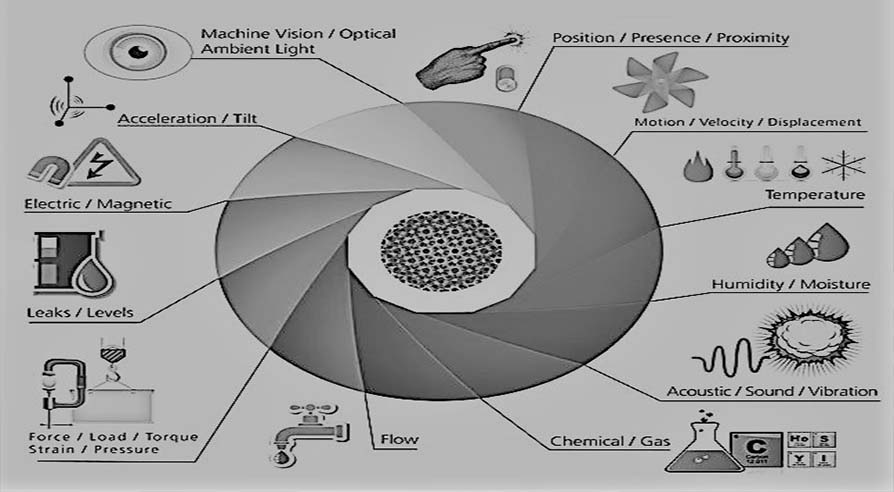

I think Liza's lecture is an amazing source to understand this week shared above in references. You can also checkout her Webpage : Soft circuiteer to explore more under this week. Otherwise my understanding is Microcontroller accepts two types of inputs depending up on the type of sensor i.e. analog or digital. I was trying to upload blink code in lilypad but it would'nt give me access, after almost few hours of trouble, thing to notice: If its analog that means it will show different range of values like light intensity varies so it will show values from 100-300-290 etc. But in digital it doesnt get affected by environment noises and shows discrete values like 0-1-0-1as if its only concerned if it is On or OFF. and we have Analog / digital readings, output, sensors. The image below shows some of analog sensors and some of digital sensors. Analog like LDR for light, Temperature sensor, Humidity sensor etc. Digital like different types of switches, tilt switch.

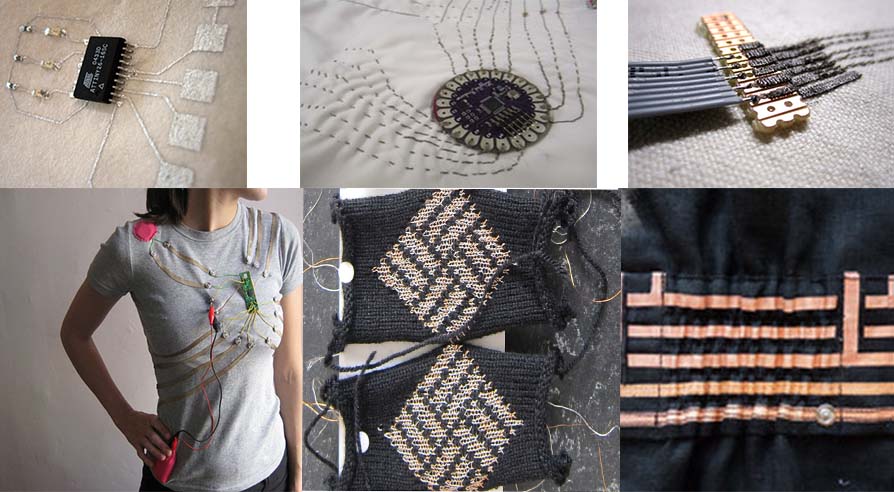

Technology is increasingly becoming part into our daily clothing to enhance and augment our daily interactions. No longer just for performance tracking or medical uses, circuits will become embedded into the fabrics we use to shield and express ourselves. Below are the few projects showing how Soft and Hard connections are done :

In the above image , we see conductive threads, tapes and fabrics being used with electronic components and well embedded in the wearables which are used for different purposes.

Possible components

There are different tools and components you can play with this week.

1. Multimeter an electronic measuring instrument that combines several measurement functions in one unit. A typical multimeter can measure voltage, current, and resistance.

2. An Arduino is an open hardware development board that can be used by tinkerers, hobbyists, and makers to design and build devices that interact with the real world. IDE is the official integrated development environment (IDE) for the Arduino. The Arduino IDE is open source software which is written in Java and will work on a variety of platforms: Windows, Mac, and Linux.

3. Traces will be made either using copper tape or Conductive thread which are ideal for introducing electronics into textiles projects. The thread looks and behaves like conventional sewing thread with the added bonus of being conductive, allowing the thread to be used in the place of wires, with conventional electronics whereas the tape itself is made of thin pure copper so its extremely flexible and can take on nearly any shape. You can easily solder to it, and the tape itself can carry current just like a wire. On the back is an electrically conductive adhesive. 4. Sensors and other components would be like LDR which would be my analog sensor vibration motors for this week as I can easily programm and use on arduino but converting them to soft circuit was a challenge initially.

Digital sensor

In digital sensor, I plan to make tilt sensor using LEd and my earring into a soft swatch.

1. Starting by Programming with Lilypad using FTDI cable, :

2. Trying my code with lilypad and copper tape for connections

Thats how my tilt sensor first iteration turned out

via GIPHY

3. Converting into a swatch where I again use copper tape and made multiple branches for my soft swatch!

Adding more LED's in my circuit and made a soft swatch!

Analog sensor

It took me long to implement what can I do in this one, So I chose LDR and Vibration motor with Arduino. Its not electronics which is an issue, understanding it in Soft connections is something takes time. 1. Starting by Programming LDR and vibration motor in Breadboard:

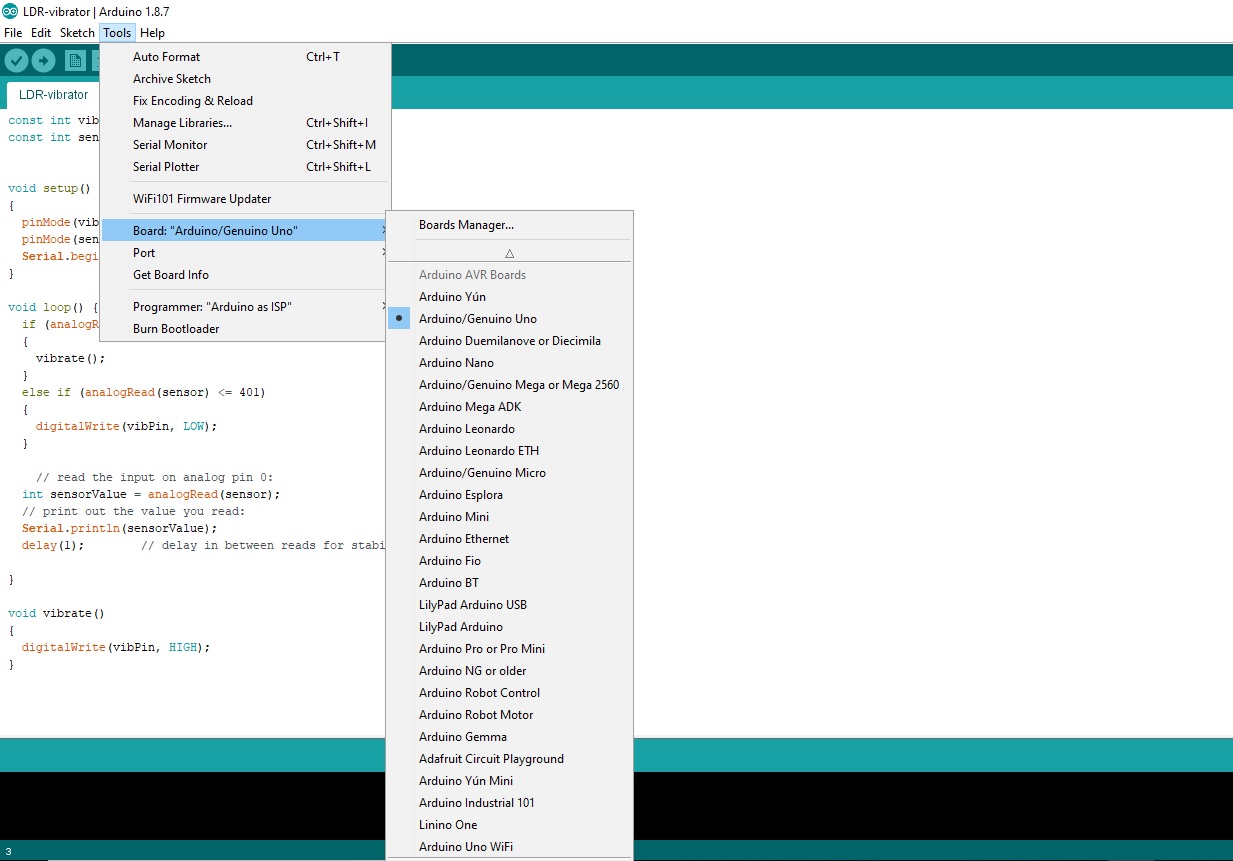

2. Using Arduino IDE to upload code on arduino, where I chose Arduino Uno as my board and port to which Arduino is plugged in.

3. Below you can check the working video of Vibration motor and LDR, the application of this project initially was to make it for blinds where they can feel this Haptic glove and understand the day and night concept.

4. First trial on breadboard, running with Arduino. Here, I am using above code where I marked 400 as point for vibration motor,So when LDR value is less than 400, vibration motor will work, if more than 400 means more light and Vibration motor will stay off.

5. This swatch is actually a Haptic glove for blinds, for understanding the conept of Day and Night or intensity of light.

Also to bring ths to notice that when driving a motor with a microcontroller like arduino, it is important to connect a diode in parallel to the motor. This is also true when driving it with a motor controller or transistor. The diode acts a protector against voltage spikes that the motor may produce when rotates. Without the diode, these voltages could easily destroy your microcontroller, or motor controller IC or zap out a transistor. When simply powering the vibration motor directly with DC voltage, then no diode is necessary.The 0.1µF capacitor absorbs voltage spikes produced when electric current to the motor windings, open and close. The reason we use a transistor (a 2N2222) is because most microcontrollers have relatively weak current outputs, meaning they don't output enough current to drive many different types of electronic devices. To make up for this weak current output, we use a transistor to provide current amplification. This is the purpose of this 2N2222 transistor we are using here. The vibration motor needs about 75mA of current to be driven. The transistor allows this and we can drive the motor. To make sure that too much current does not flow from the output of the transistor, we place a 1KΩ in series with the base of the transistor. This attenuates current to a reasonable amount so that too much current isn't powering the motor. Remember that transistors usually provide about 100 times the amplification to the base current that enters through. If we don't place a resistor at the base or at the output, too much current can be damaging to the motor. The 1KΩ resistor value isn't precise. Any value can be used up to about 5KΩ or so. Converting my circuit into a Swatch, where I am using copper tape and replicating itinside the glove.

6. So that reader could understand the application, I found this video, where when someone keeps his finger on the bracelet, it makes that pointdarker and sends a message to the app to switch on vibration on the other bracelet. Well, I dont know if this bracelet has been made on similar concept.

Another trial with "Tilt switch"

Here , I am converting above SOFT to HARD swatch,

Connect FTDI cable ( I have used FTDI Serial TTL-232 USB cable) and you can download FTDI drivers from refered links above. Using Arduino IDE to write my code which you can find in reffered links abovefor download. Update your libraries if required for specific sensors. Here, I used tilt module which allows you to detect orientation or inclination. By connecting this tilt sensor with arduino we can control LED, buzzer or other output devices. Here we interfaced tilt sensor with arduino board and LED as output indicator, remember to connect 10KΩ bias resistor between ground (GND) and one terminal of tilt sensor that is connected to arduino digital input pin.

Using Lillypad with Tilt Module

-Using Alligator clips for making connections

-Using Arduino UNO first and finally with Lillypad

-Using Breadboard- Green LED and a Tilt switch

Putting Soft sensor on hard Cylinder

After