WEEK 03 - Computer Controlled Cutting - FAB LAB KAMAKURA¶

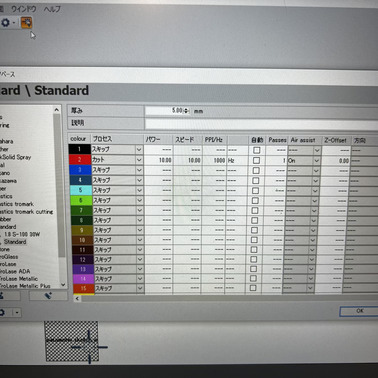

Model and Software¶

Model is a [Trotec Speedy 100]

Focus¶¶

Focus is set by ensuring the material is the correct distance from the laser. You may vary this in certain situations, for example:

Engraving: By moving the laser further away you can get a softer, fuzzy edged look Engraving: When you have a harder material such as glass, you may want to move the laser closer if rasing power and slowing speed is not getting you the results you would like Cutting: For harder and thicker materials in order to reduce the power needed and increase speed, the laser may be moved closer to the material

The focus on the laser in Kamakura needs to be set manualy which is done using the focusing gauge, which you position on the side of the laser, and move the material up until it touches the gauge.

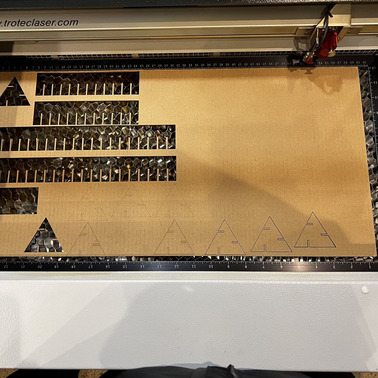

KERF¶

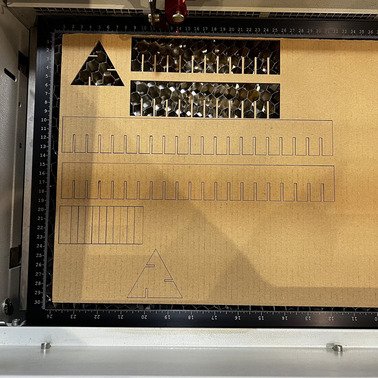

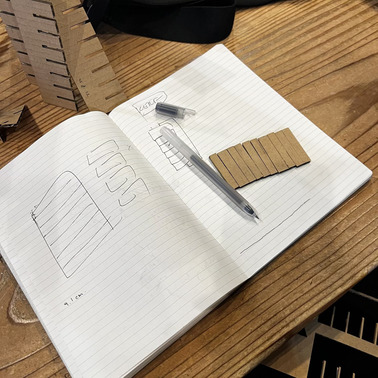

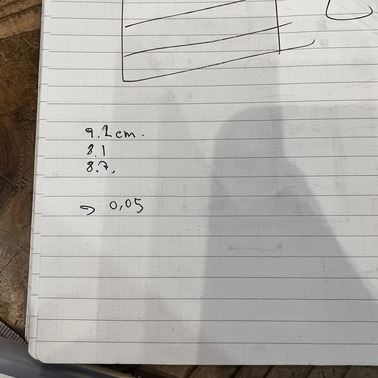

To test the lasercutter we checked the curf necessary for the cardboard.

we also used this Kerf generator to cut out Kerf testing shapes: https://doyolab.net/appli/kerf_check/kerf_check.html

so 0.05 is the amount of material that is lost to laser!

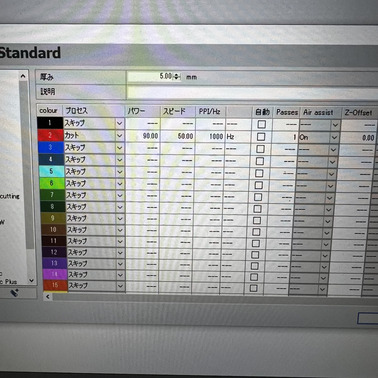

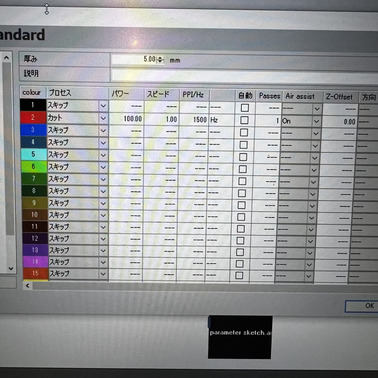

Rate¶

Rate (frequency) is known as Hz in the settings on a Trotec laser cutter. It can impact the quality of cutting on the laser cutter.

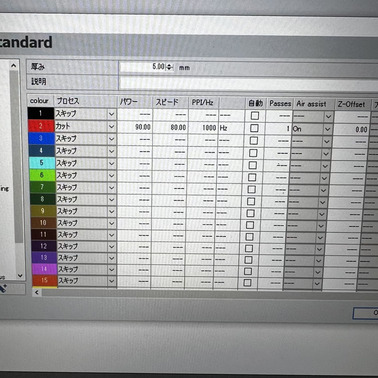

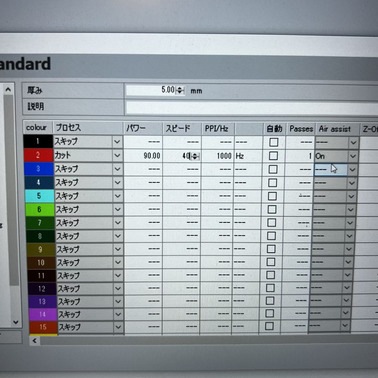

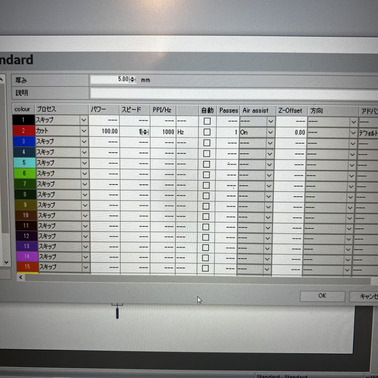

we ran experiments with many different speeds and strengths to check which would allow us to cut the cardboard with the most clean and least energy demanding settings.

Conclusions/Results¶

For cardboard:

I also had to consider that the cardboard in itself has some