Fully Printed Axis

Documented by Babken Chugaszyan 17/01/2023.

During Fabx17 at Bali Jean-michel Molenaar tried to print 1m rail using SainSmart INFI-20 Belt 3D Printer (there were 2 of this printers available there). The electricity on the island was not stable and after 3 attempts of printing and failing he quit and made the circular Semut machine.

As soon as I noticed SainSmart INFI-20 hanging on the wall at Waag I thought of trying to print 1m long axis again.

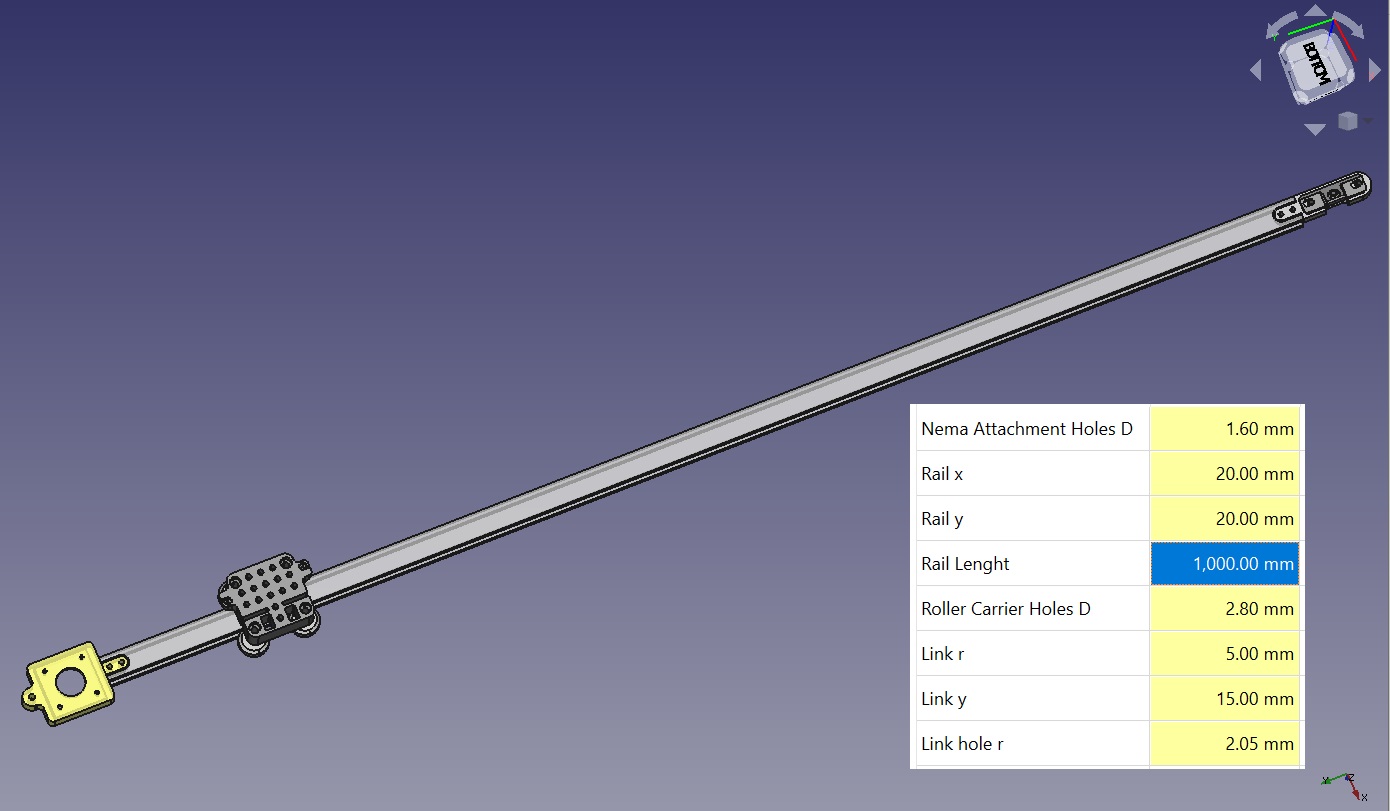

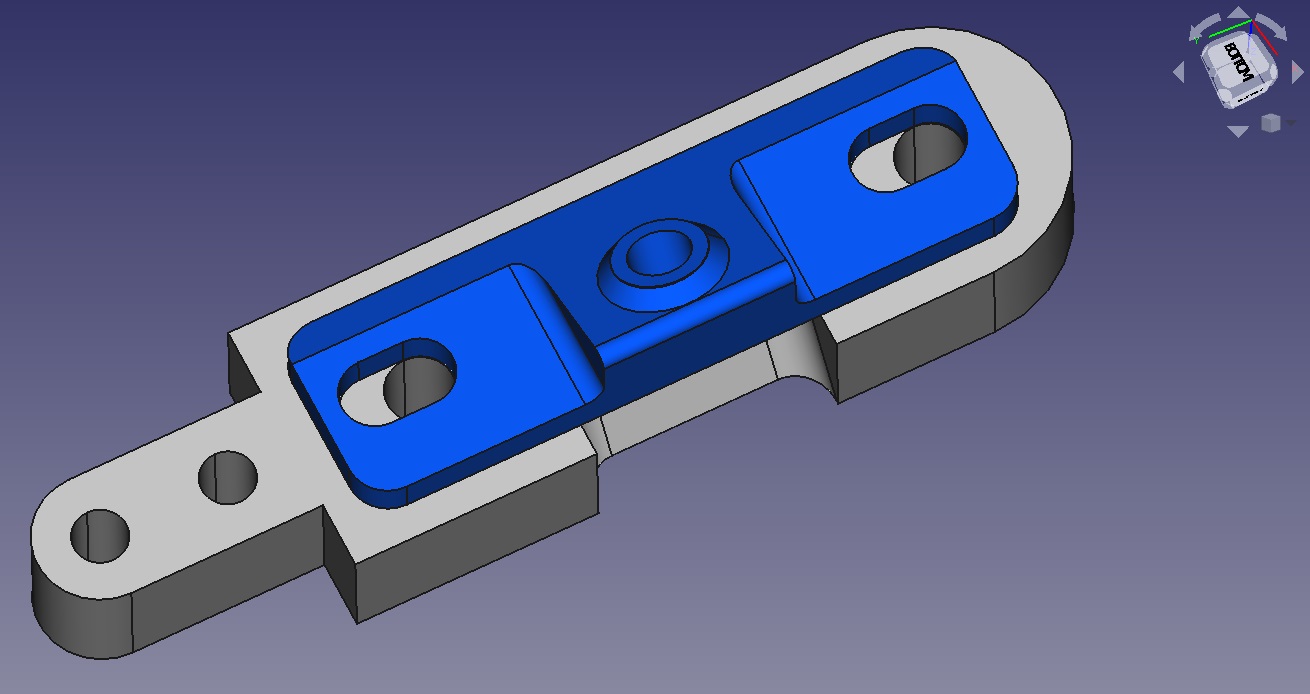

For the rail I used the design from last year's Dilijan's and Kannai's machine building week machine building week. I just changed the "Rail Lenght" to 1000mm.

For the rail I used the design from last year's Dilijan's and Kannai's machine building week machine building week. I just changed the "Rail Lenght" to 1000mm.

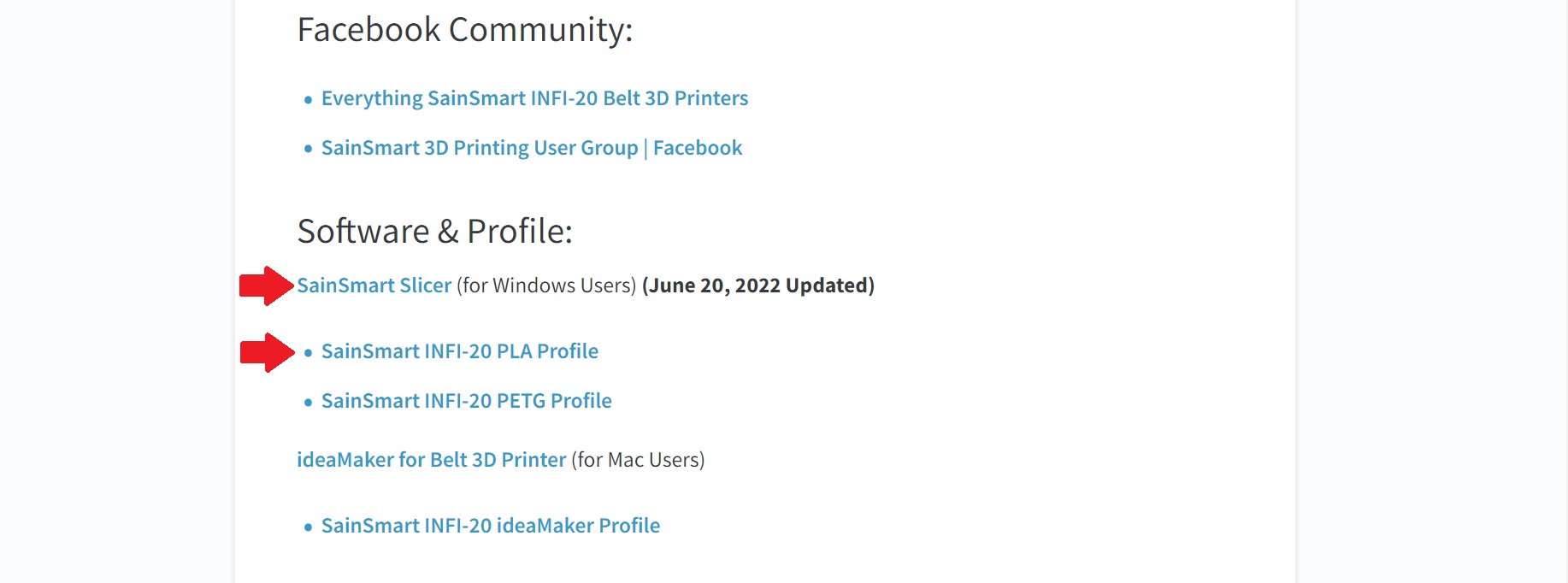

I downloaded the SainSmart Slicer and PLA profile from the SainSmart Resources.

I downloaded the SainSmart Slicer and PLA profile from the SainSmart Resources.

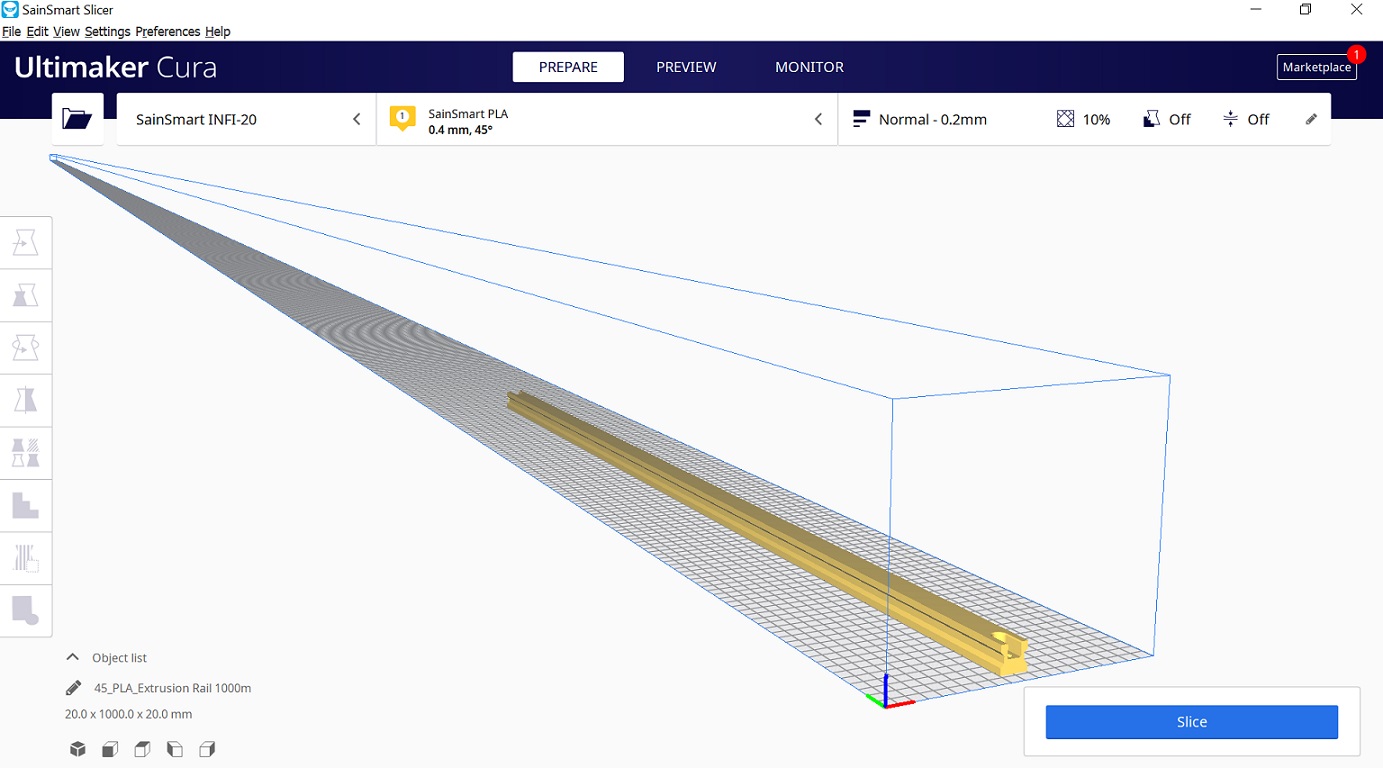

Added the printer with the profile and there you go.

Added the printer with the profile and there you go.

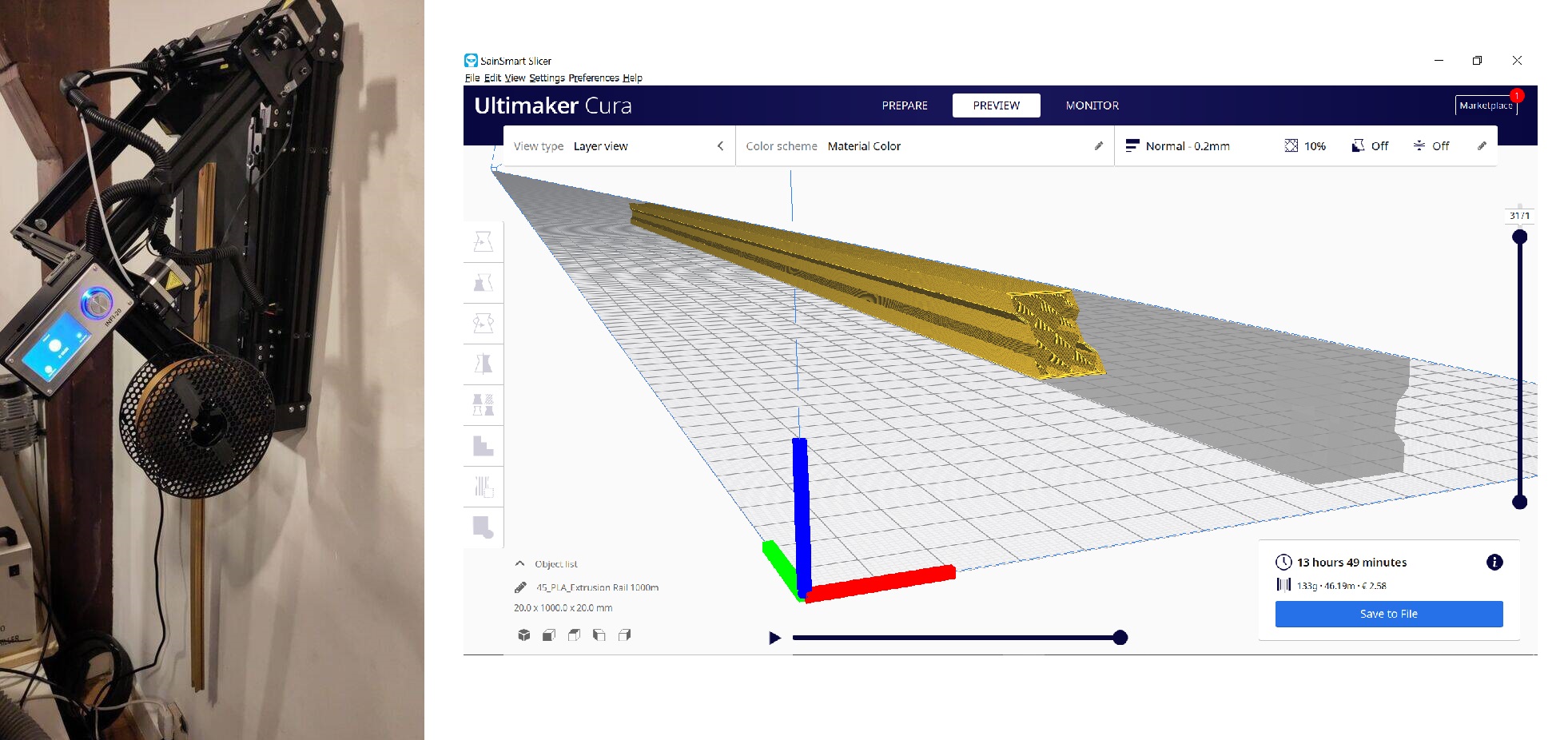

10% infill 3 shells and 14hours of printing and we got this rail. Usually Henk doesn't leave is printers on overnight for safety reasons (the Waag fablab is situated in 15 century 1482 to be exact castle). I was luky enough that the day I started the long print we had a party and Henk stayed overnight with some folks.

10% infill 3 shells and 14hours of printing and we got this rail. Usually Henk doesn't leave is printers on overnight for safety reasons (the Waag fablab is situated in 15 century 1482 to be exact castle). I was luky enough that the day I started the long print we had a party and Henk stayed overnight with some folks.

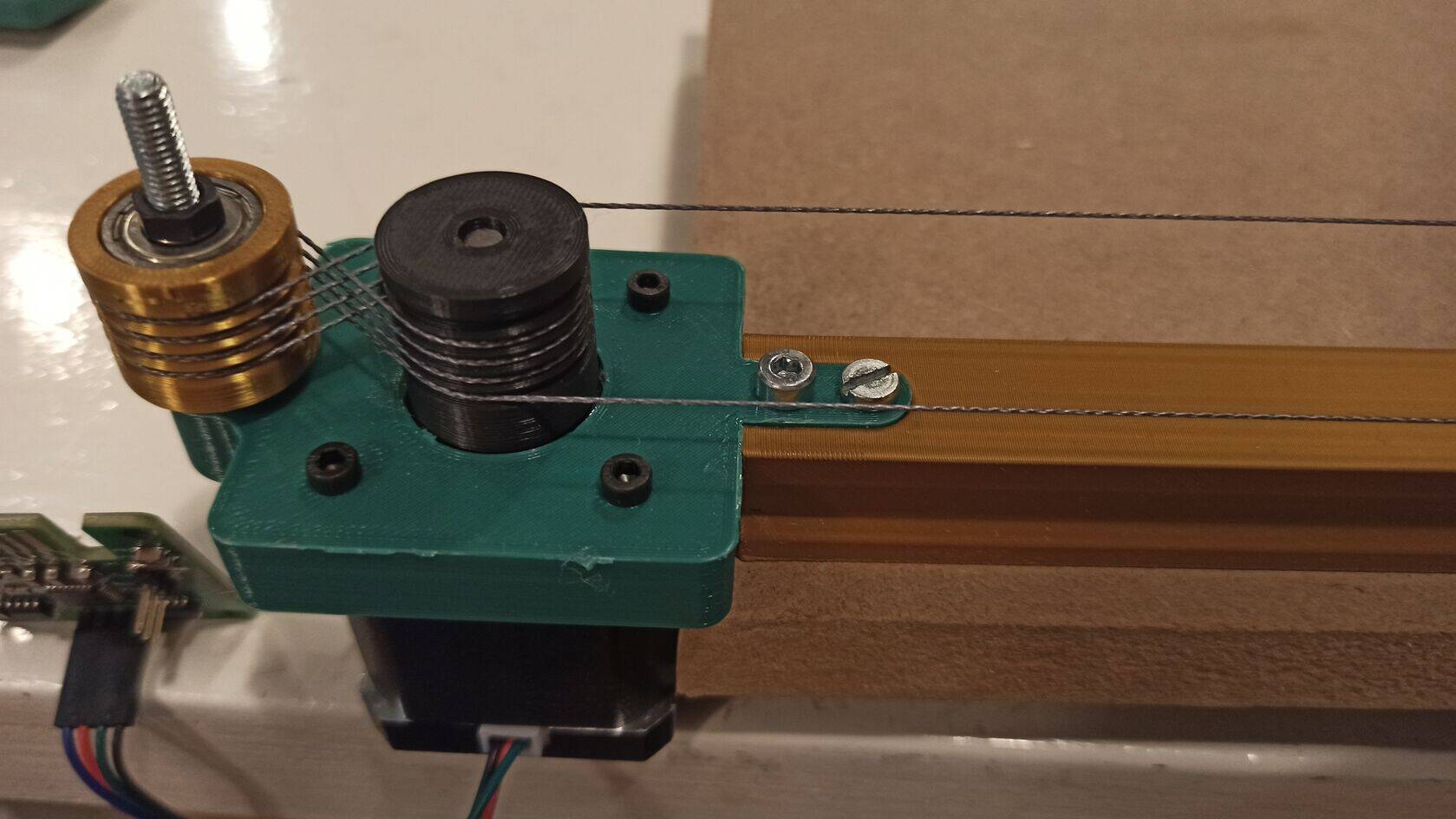

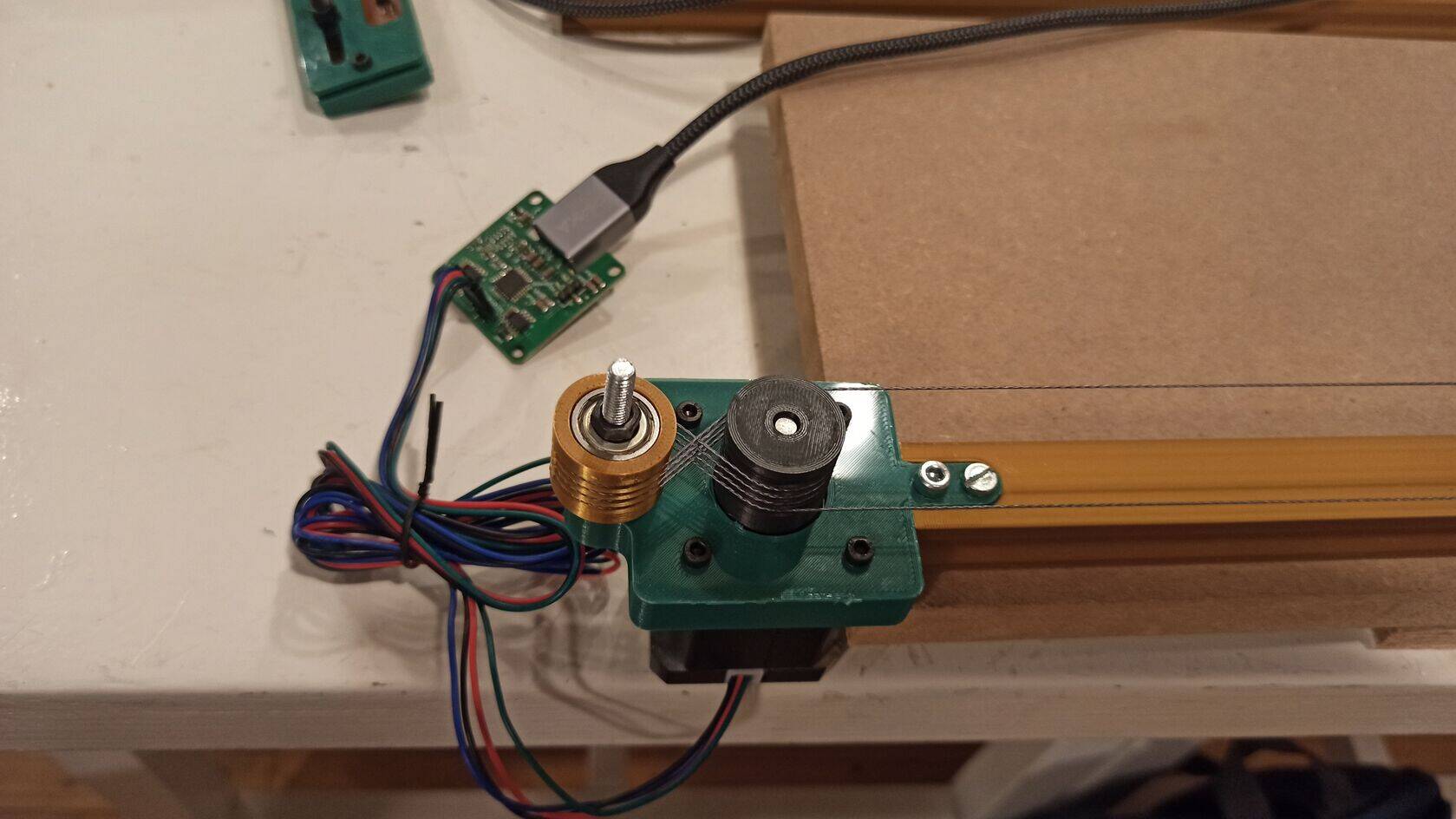

Among other projects Quentin introduced Beehive-axis which was using extrusion rails and 3d printed parts to build a customizable machine. What I liked the most in this project was that the design enabled to adjust wire tension.

Among other projects Quentin introduced Beehive-axis which was using extrusion rails and 3d printed parts to build a customizable machine. What I liked the most in this project was that the design enabled to adjust wire tension.

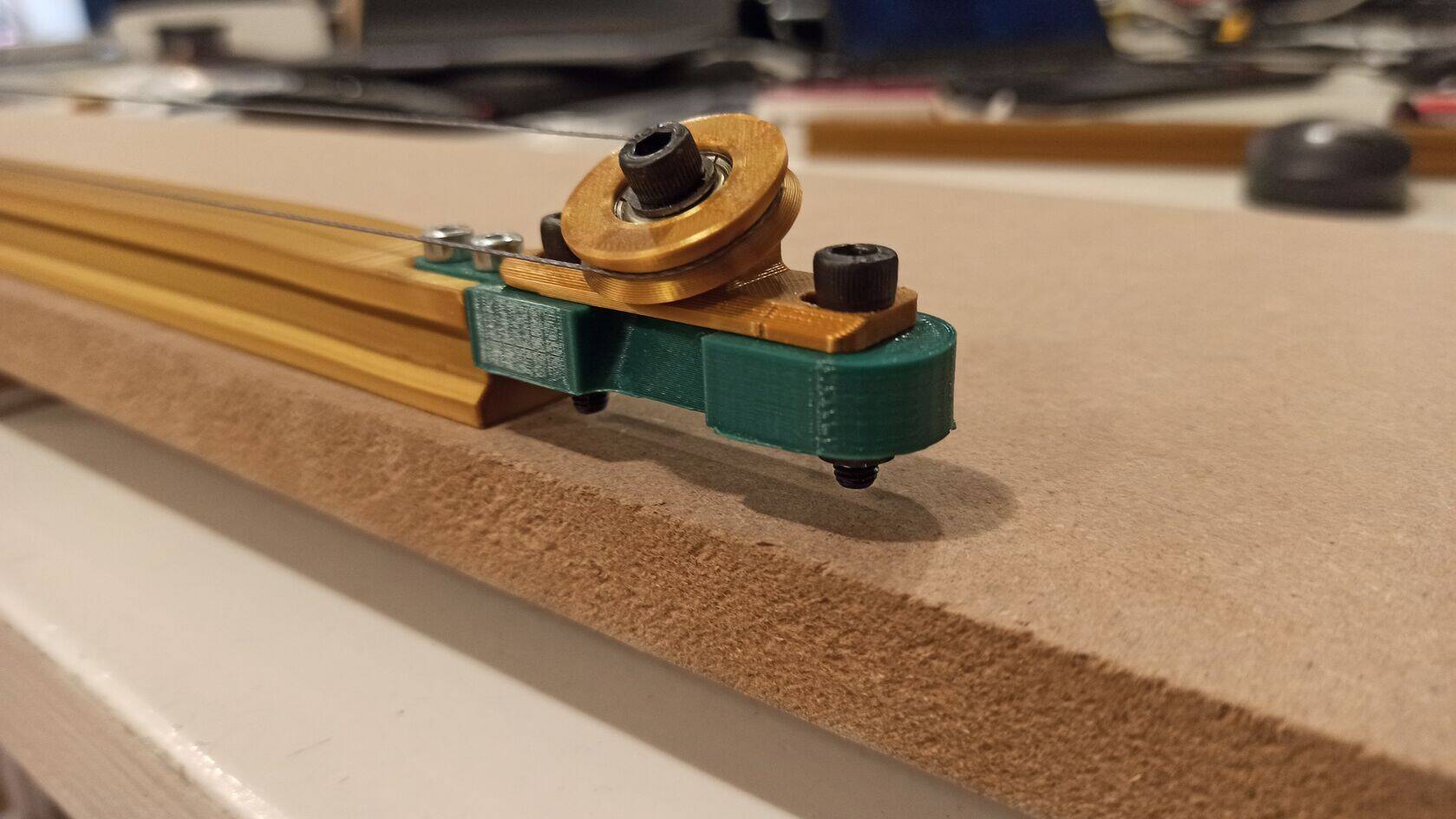

I modified the idler mount part to be able to fit beehive's pulley_holder.

I modified the idler mount part to be able to fit beehive's pulley_holder.

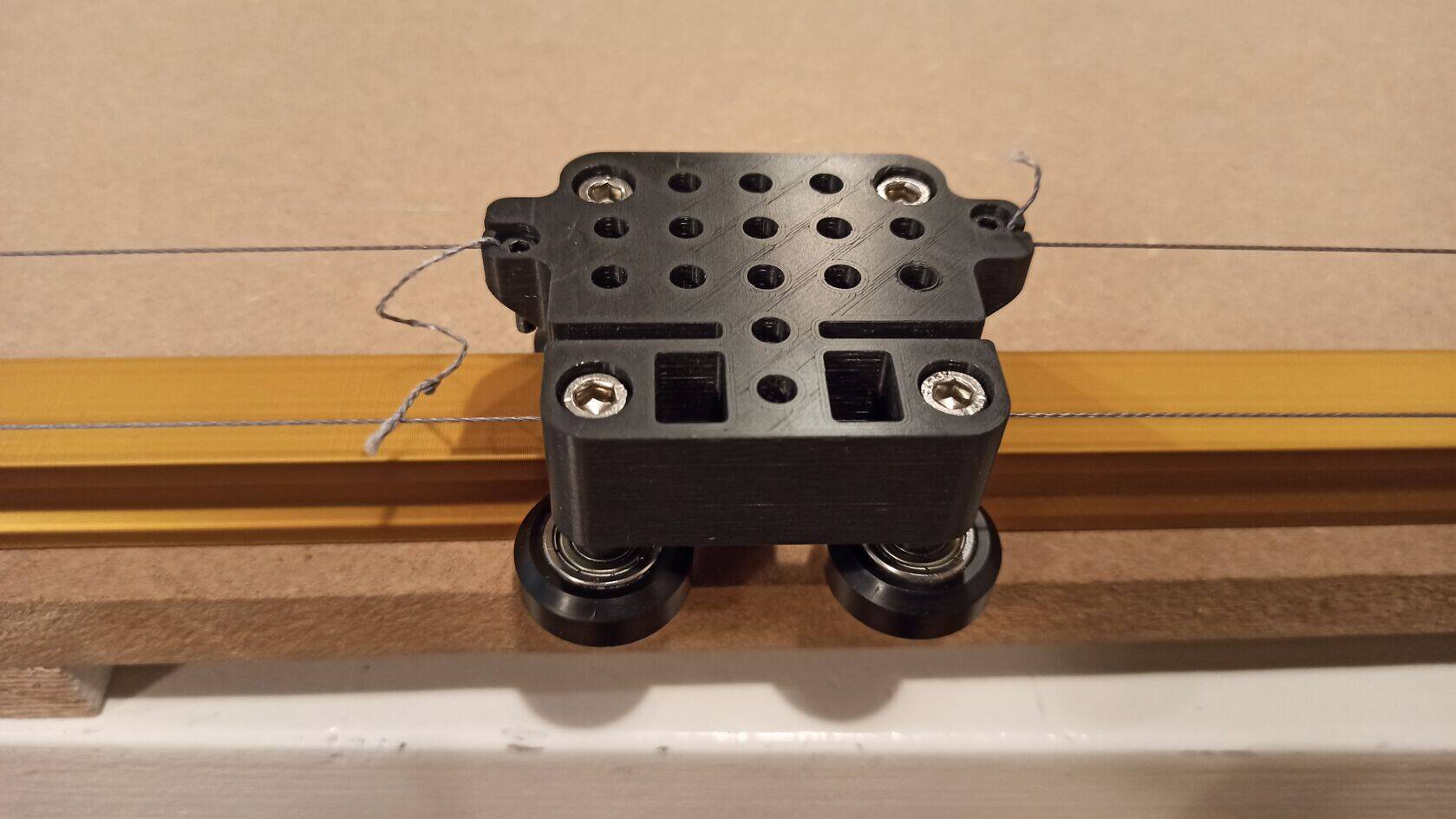

Quentine printed all the Beehive parts to make a machine but for some reason the extrusion rails available at bootcamp didn't fit the parts. As a result I had many parts of the rail available like capstans pulleys etc. Quentine modified the carriage to fit the rail.

The only problem was that the rail was a bit bended and was not that strong to hold the wire tension. I came up with a solution to attach it to an MDF leftover I found near the Shopbot machine. The rail is attached to the board by 5 M4 bolts, one in the middle and two from each side.

Quentine printed all the Beehive parts to make a machine but for some reason the extrusion rails available at bootcamp didn't fit the parts. As a result I had many parts of the rail available like capstans pulleys etc. Quentine modified the carriage to fit the rail.

The only problem was that the rail was a bit bended and was not that strong to hold the wire tension. I came up with a solution to attach it to an MDF leftover I found near the Shopbot machine. The rail is attached to the board by 5 M4 bolts, one in the middle and two from each side.

With the help of Miriam from Seoul we installed the fishing line.

With the help of Miriam from Seoul we installed the fishing line.

Codes and testing

Quentine attached the Stepper driver board from modular things.

And kindly showed and explained how to run it.

In order to run it you have to go to Modular Things

and paste this code.

And kindly showed and explained how to run it.

In order to run it you have to go to Modular Things

and paste this code.

//code Quentine used to run drive the axis.

stepperBabken.setCurrentScale(0.3);

stepperBabken.setStepsPerUnit(800 / 64);

stepperBabken.setVelocity(300);

stepperBabken.setAccel(500);

async function main() {

let pos = 0;

for (let i = 0; i < 6; i++) {

pos = pos == 0 ? 850 : 0;

await stepperBabken.absolute(pos);

}

}

main();

Here is the rail in motion.

Presentation

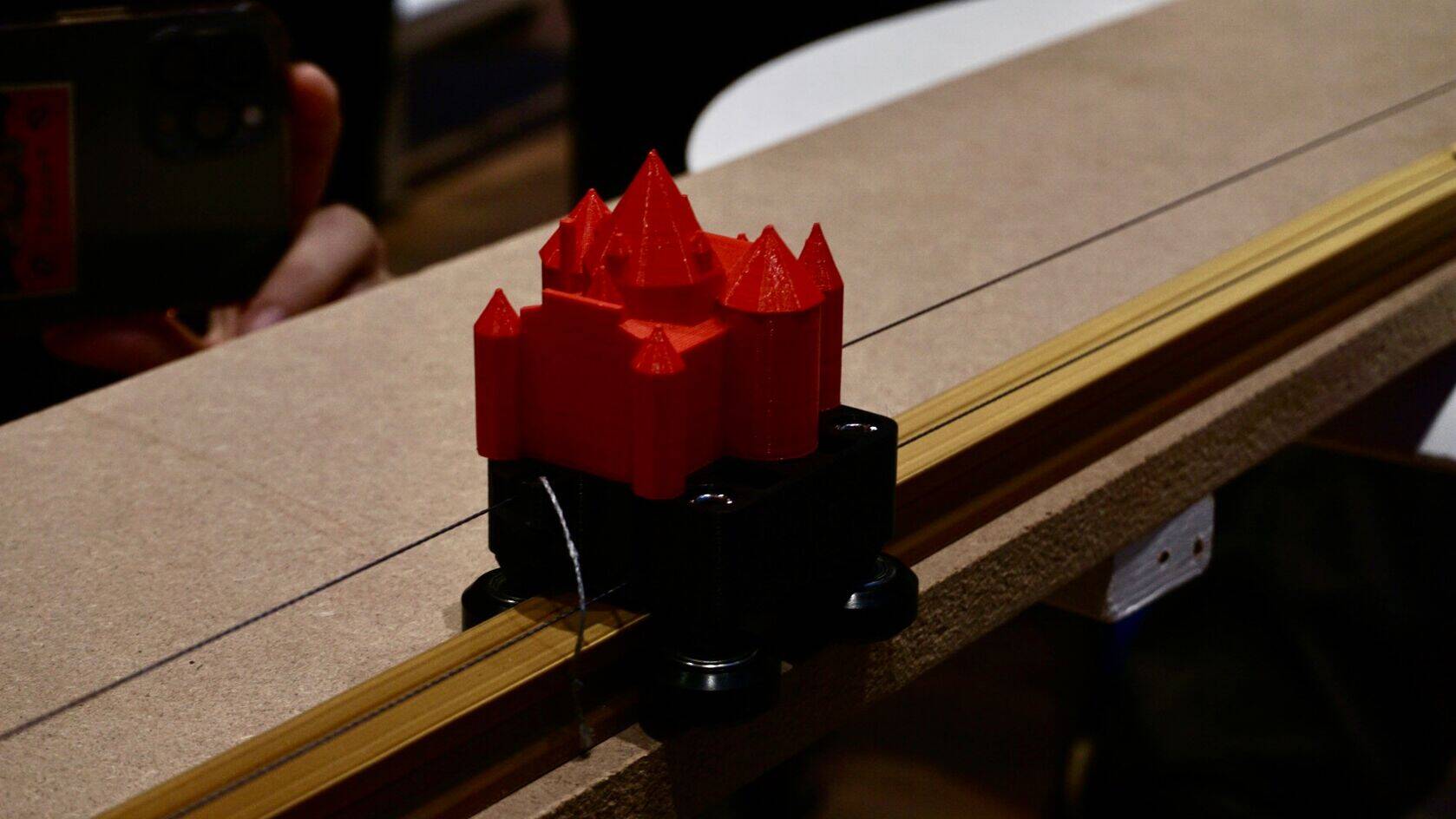

The next day among other project we also presented this rail.

Rico brought the 3d print of Waag castle and attached it to the carriage.

Rico brought the 3d print of Waag castle and attached it to the carriage.

Someone offered to put Quentine's magic button machine next to it and attach a finger to the carriage this is the result.

Someone offered to put Quentine's magic button machine next to it and attach a finger to the carriage this is the result.

Files

If you need the capstans, carrier and pulleys you can find them here Beehive-axis.