10. Applications and Implications¶

This week I reviewed my final project and constructed a more concrete plan.

Final project overview¶

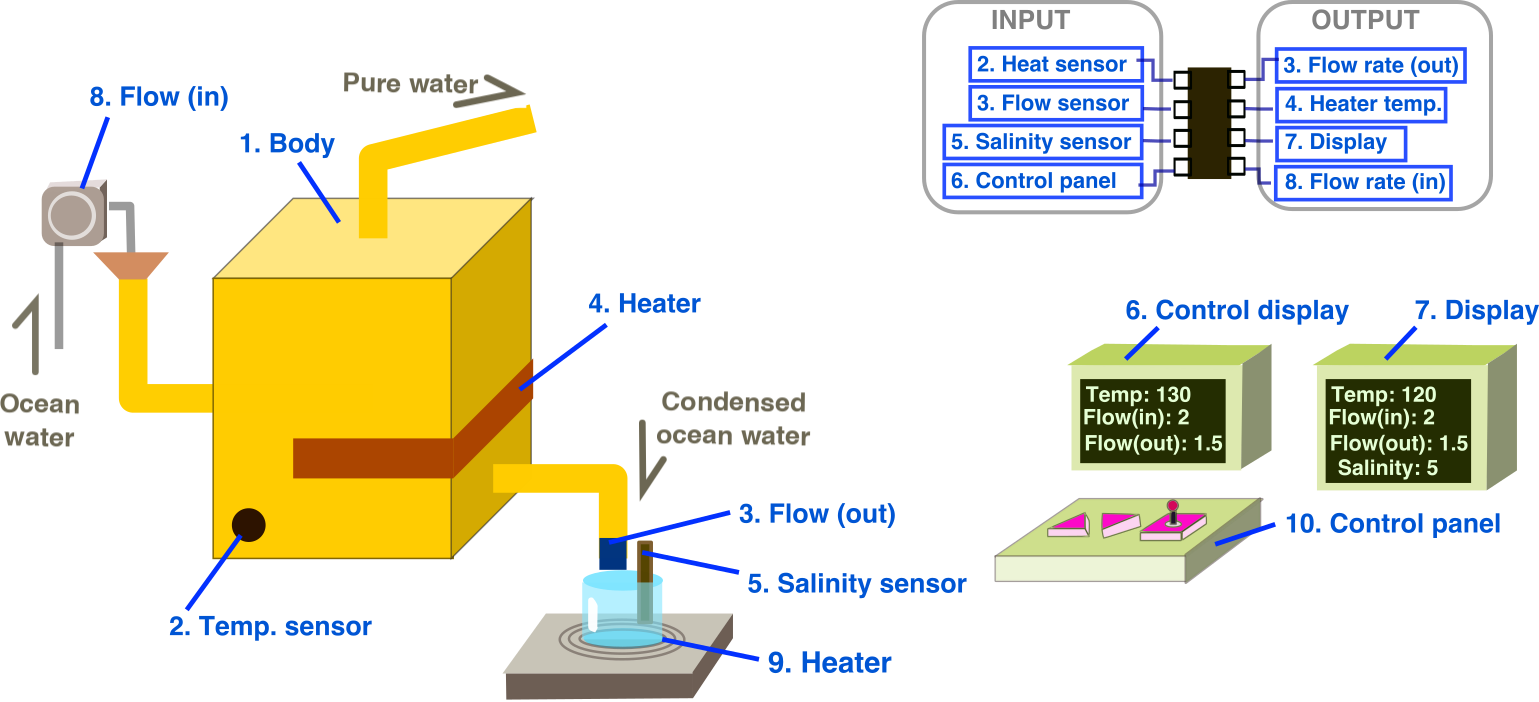

Mini Salt Factory - an interactive installation that distillates ocean water to make water and salt. It aims to help children understand about chemical engineering.

What will it do?¶

- An interactive learning material for chemical engineering about

- how chemical plants look like in general

- what the concept of “continuous process” is

- what control parameters are involved when designing/running a chemical plant and how they affect the production

- Target age: 9+ (younger age can also learn from watching demo)

- Scale: approximately 0.6 cubic meter.

Why make it?¶

There isn’t many learning/teaching materials on chemical engineering.

Yes - there are various existing learning materials about chemistry, but most of them focus on reactions inside laboratories.

However, the mechanism can be totally different when coming to large scale production.

Reactions/productions designed for a beaker can easily fail in a factory.

This installation focus on the engineering side of chemistry, and informs learners about:

- the basics of chemical engineering,

- the concept of a “continuous” process

- the concept of systematic thinking (through experiencing how changing even just 1 control parameter affects the whole system)

What materials and components will be used?¶

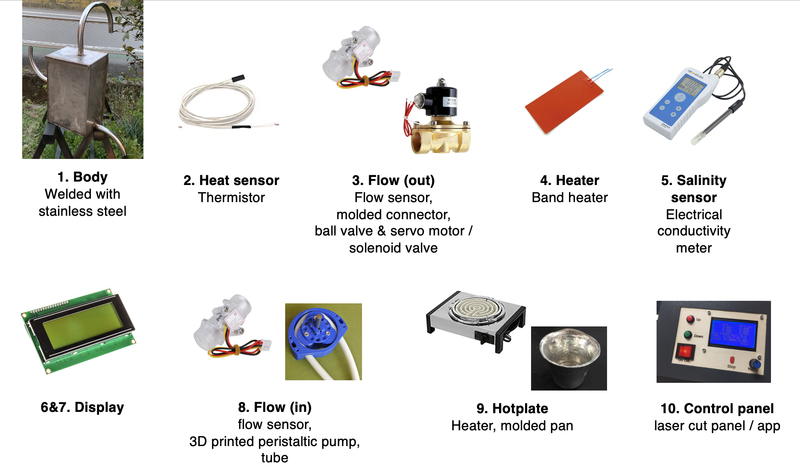

- Body: Welded with stainless steel

- Heat sensor: thermistor

- Flow (out): flow sensor, molded connector, ball valve & servo motor / solenoid valve

- Heater: band heater

- Salinity sensor

- Control display: LCD display

- Display: LCD display

- Flow (in): flow sensor, 3D printed peralstitic pump, tube

- Hotplate: Heater, molded pan

- Control panel: laser cut panel / app

Packaging: Laser cut transparent acrylic, LED, sound.

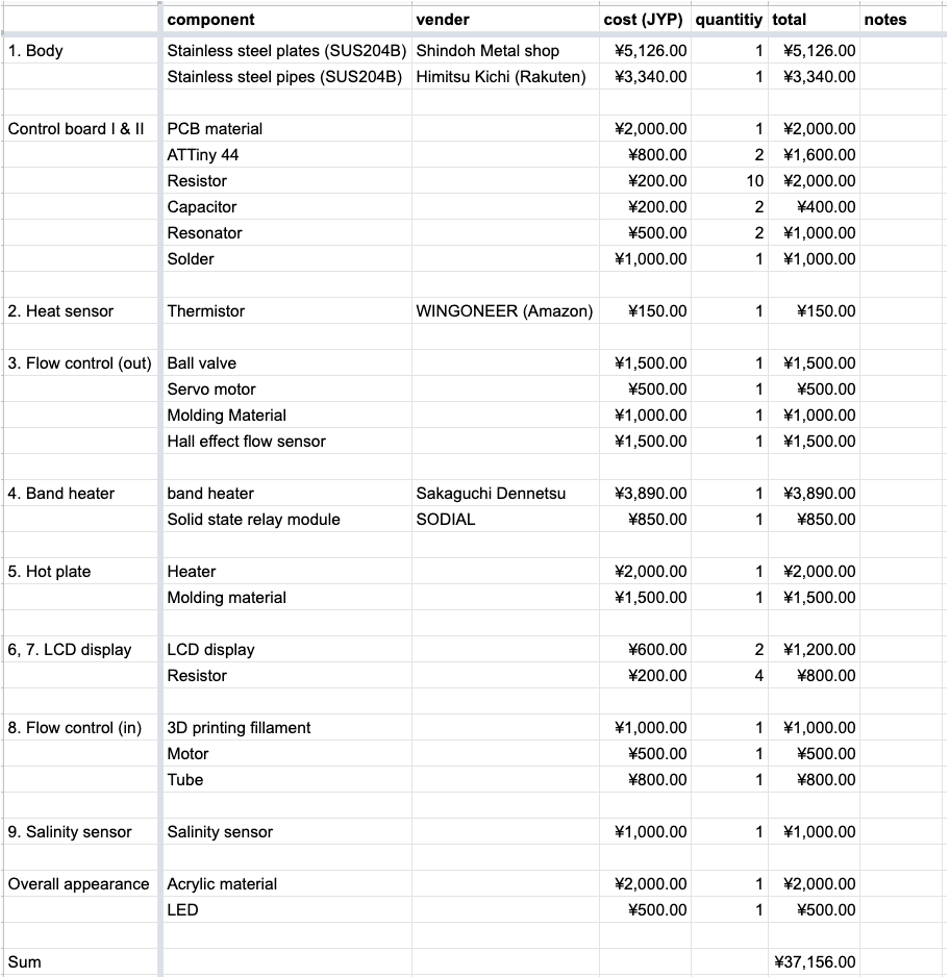

Where will come from? & How much will they cost?¶

Bills of materials¶

What parts and systems will be made? & What processes will be used?¶

- Additive fabrication processes:

- 3D printed peristaltic pump

- Subtractive fabrication processes:

- CNC machine milled circuit board

- Laser cut control panel

- Packaging - laser cut transparent acrylic

- Electronics design and production, embedded microcontroller interfacing and programming

- All the electronics part produced using CNC machine

- Communication between more than 2 boards

- System integration and packaging

- All the packaging?

- Extra: welding

- Body

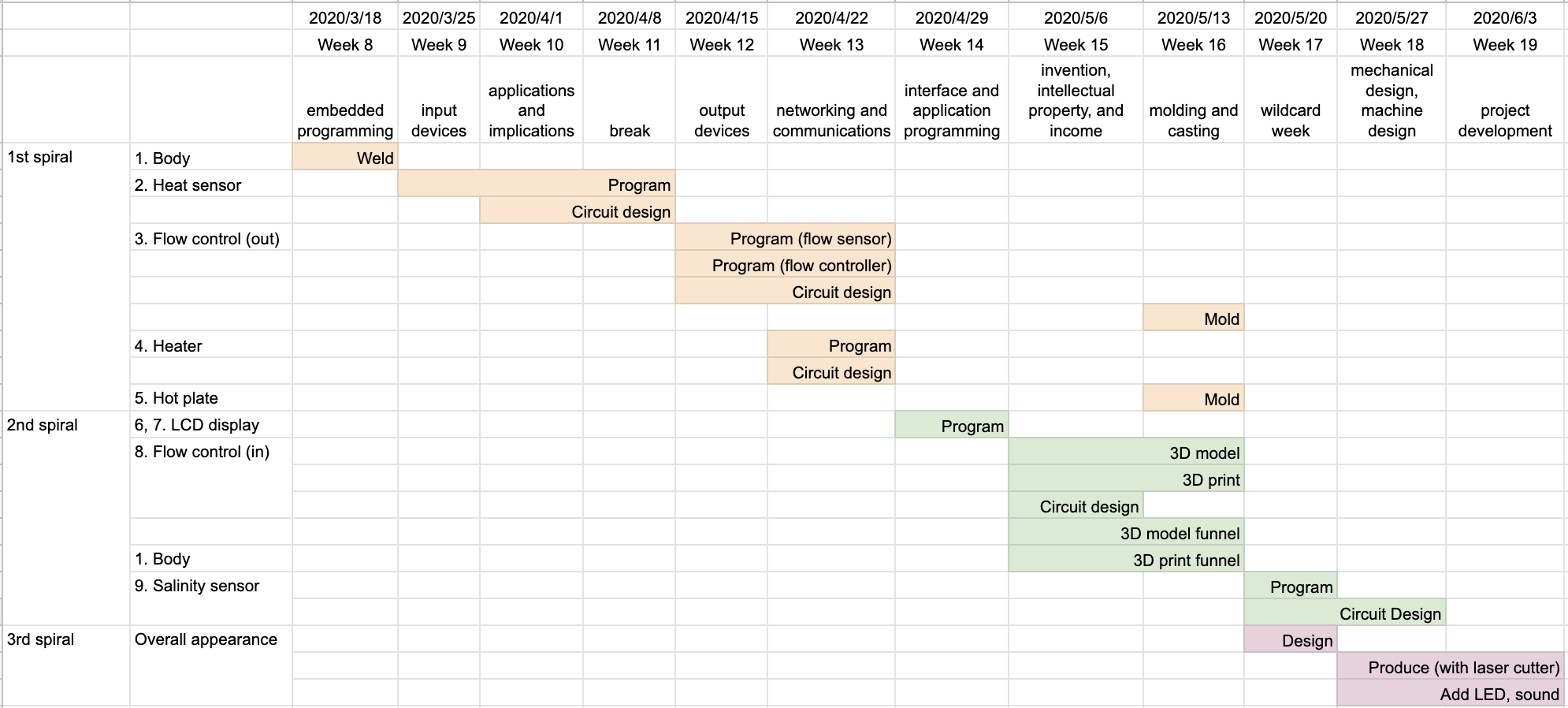

How is the project going to be developed?¶

This project will be developed through 3 spirals. This is the schedule.

1ST SPIRAL

I will complete 1 through 5 in the diagram to

- Generate condensed ocean water, and test with salinity sensor.

- One flow control at the exit.

2ND SPIRAL

I will complete 6 through 9 in the diagram to

- Add flow control at the entrance.

- Add device to evaporate water from condensed salt water to make salt.

- Add control panel and LCD display.

3RD SPIRAL

3rd spiral will be dedicated to updating the over all appearance of this installation including 10 in the diagram.

Who has done what beforehand?¶

- (To learn about heat control) Heat & Electricity generator using wood (Meier Ferdinand, FA2013) (page)

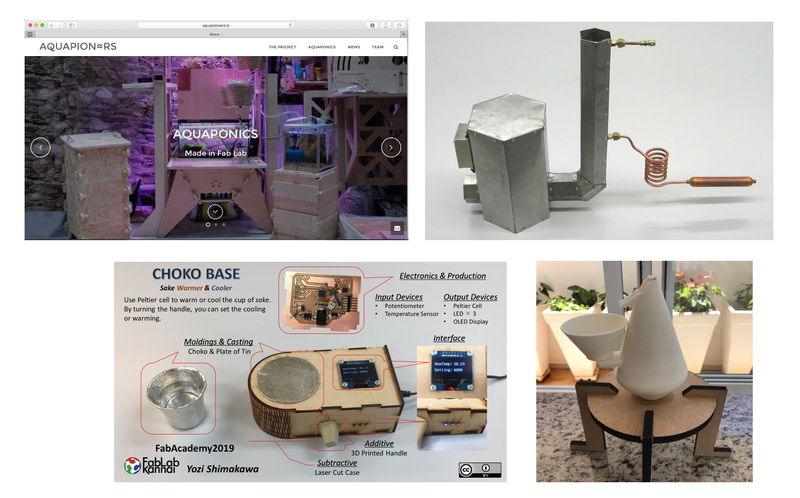

- (To learn about flow control and display) Aquaponics system (Gillaume Teyssie, FA2016) (page)

- Essential oil extractor (Laura Massaglia, FA2018) (page)

- (To learn about control parametersand display, molding a pot/pan) Sake heater (Yozi Shimakawa, FA2019) (page)

What questions need to be answered?¶

- Will children actually enjoy it? - More hands-on content? More control parameters? More activities without changing the installation itself?

How will it be evaluated?¶

Testing with children through organizing a workshop.