6. 3D Scanning and Printing¶

-

Individual Assignment

- Design a 3D object (small, few cm3, limited by printer time)

- Object could not be made subtractively

- 3D print an object

- 3D scan an object (and optionally print it)

- Design a 3D object (small, few cm3, limited by printer time)

-

Group assignment

- Test the design rules for 3D printer(s)

For this weeks’ assignment, we decided on modelling an object that satisfies the requirements for the assignment. Tinkercad was used to complete this assignment.

Tinkercad is a free, online 3D modeling program that runs in a web browser, known for its simplicity and ease of use

Modeling & Printing¶

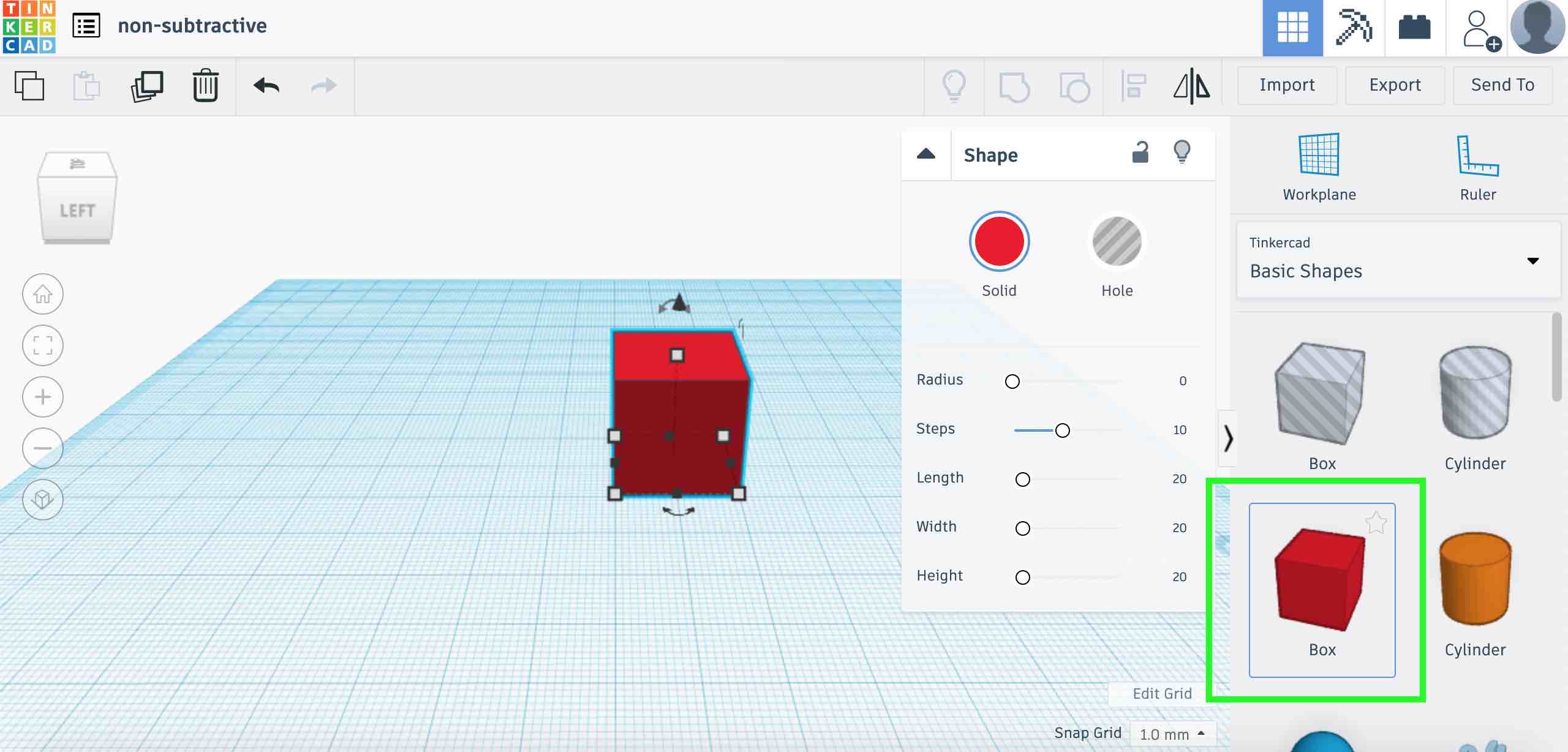

Add a Cube with desired size.

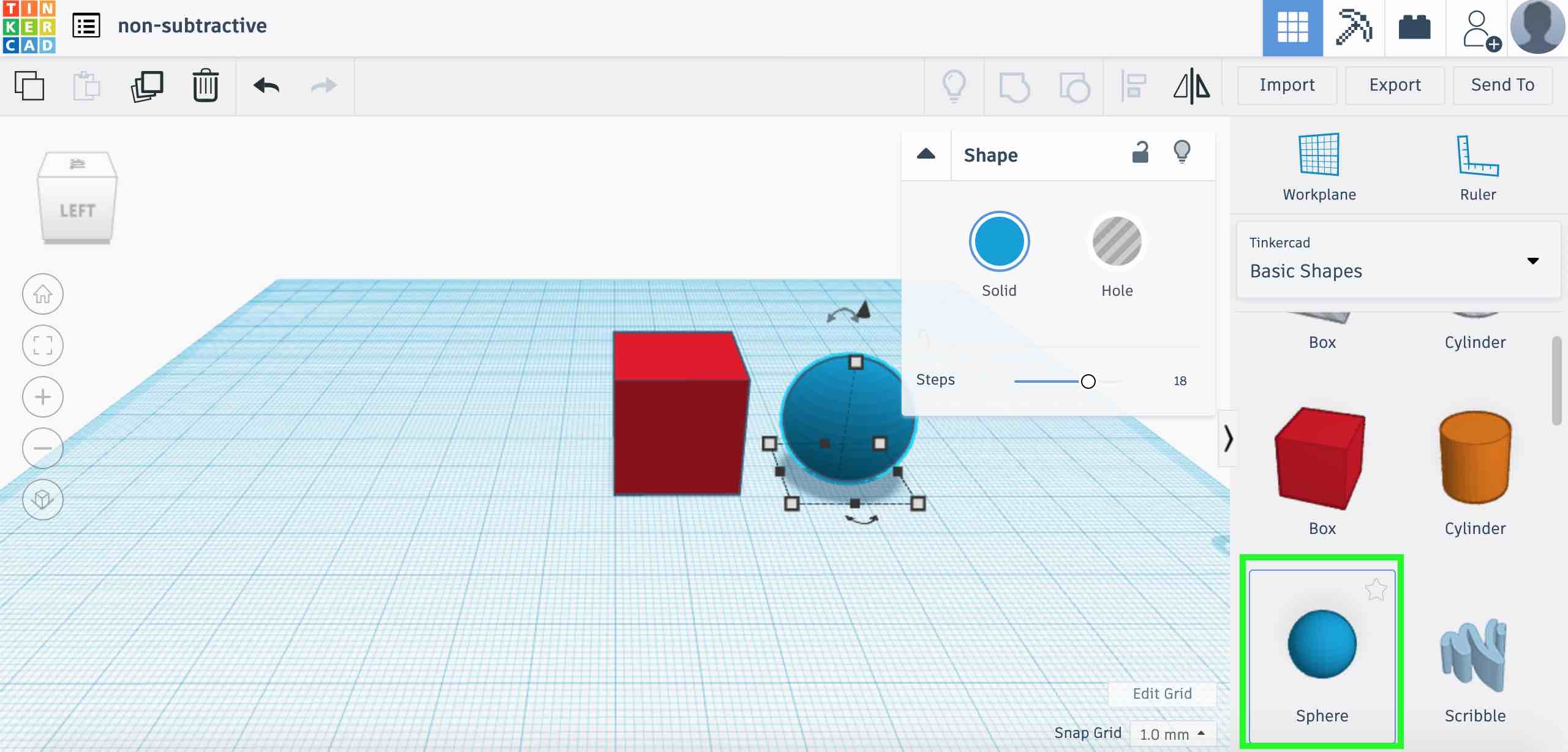

Add a Sphere with the desired size.

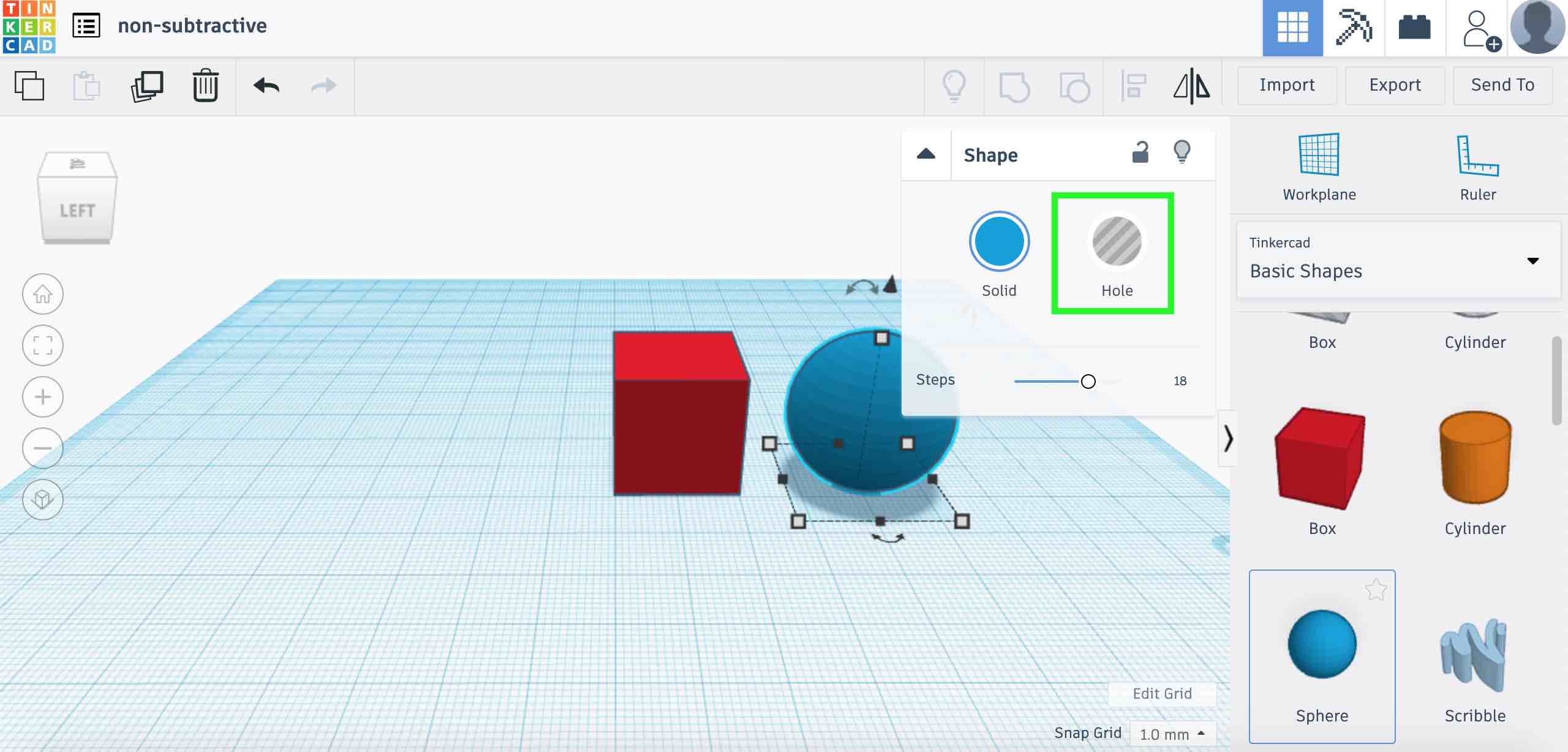

Make the Sphere Hole.

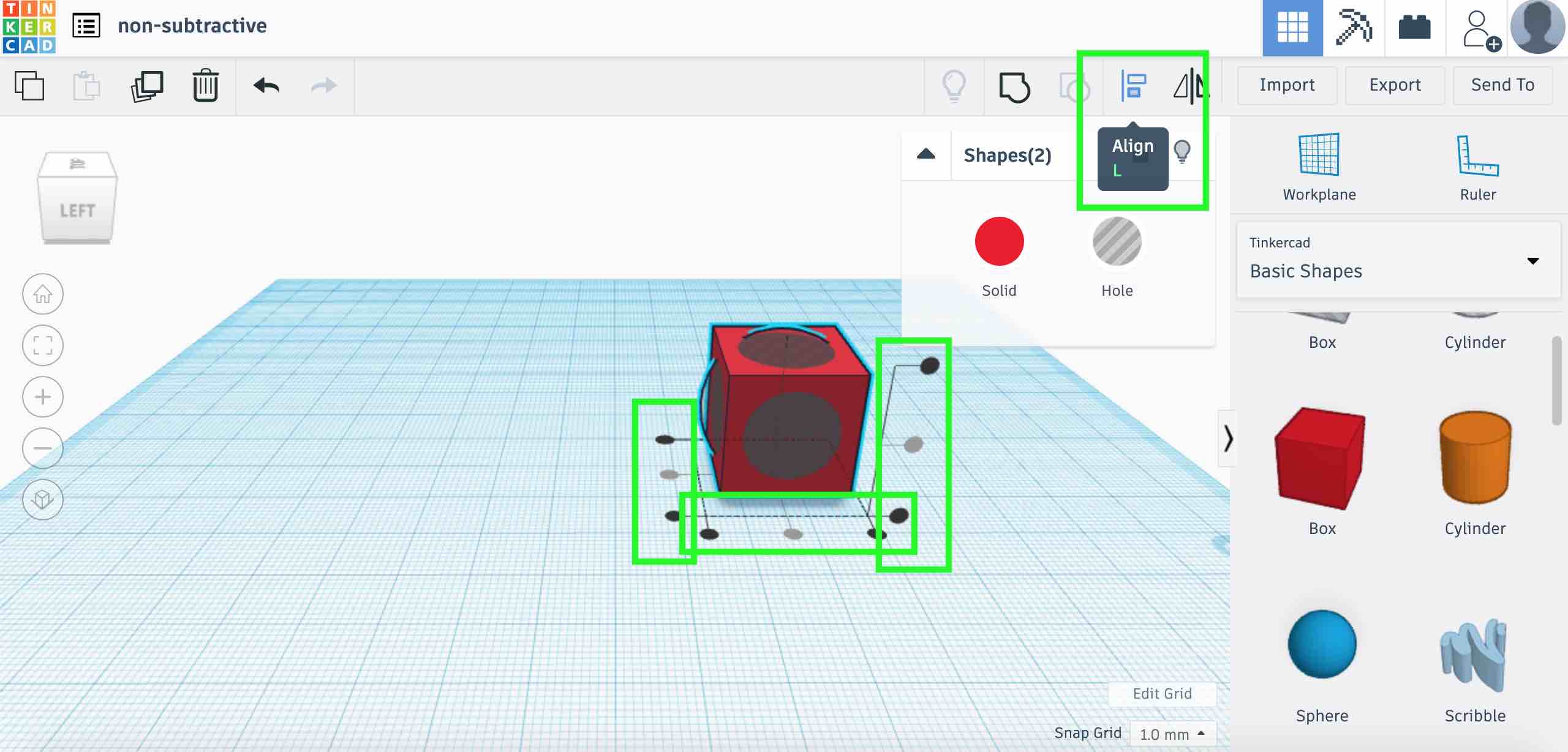

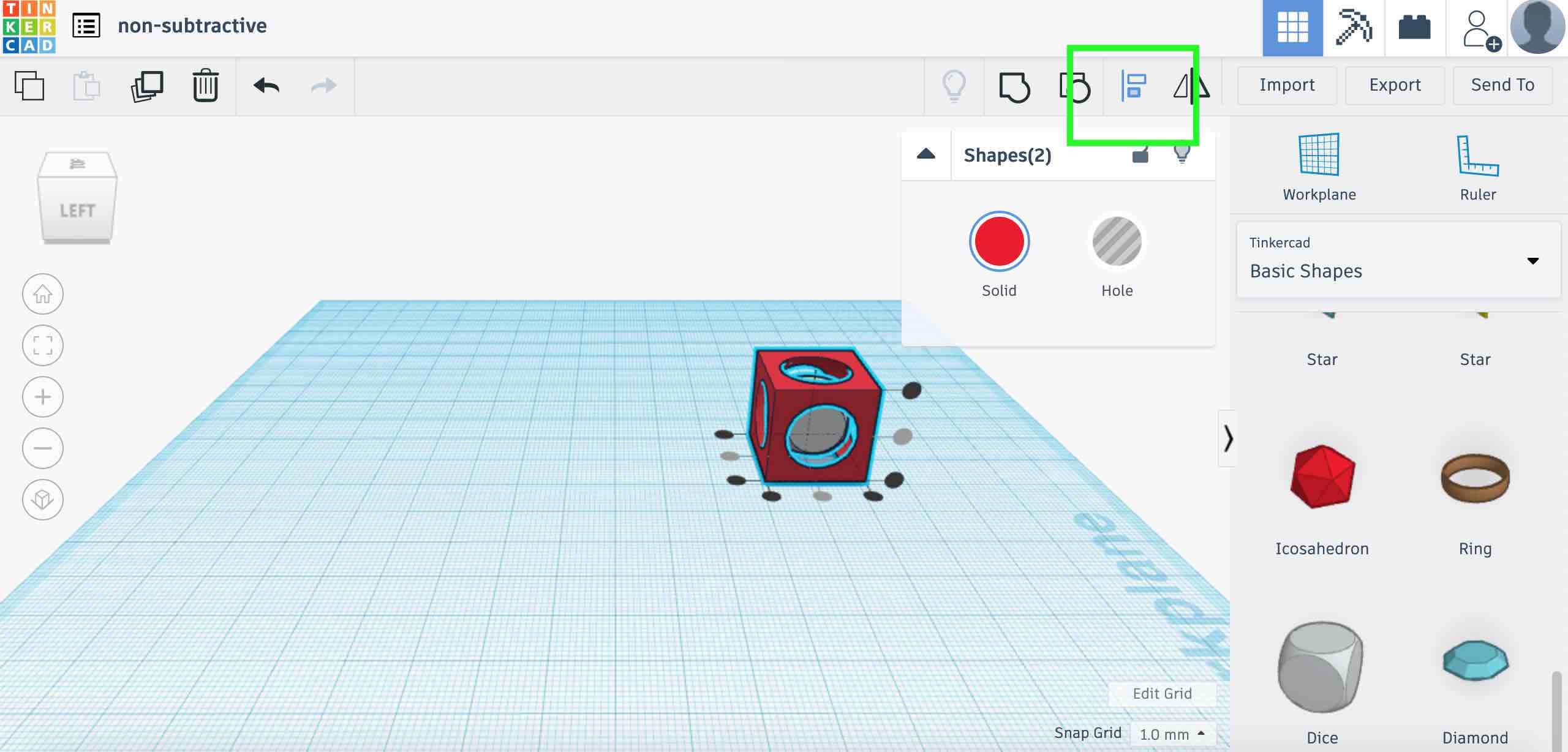

Align the Sphere with the Cube after selecting them.

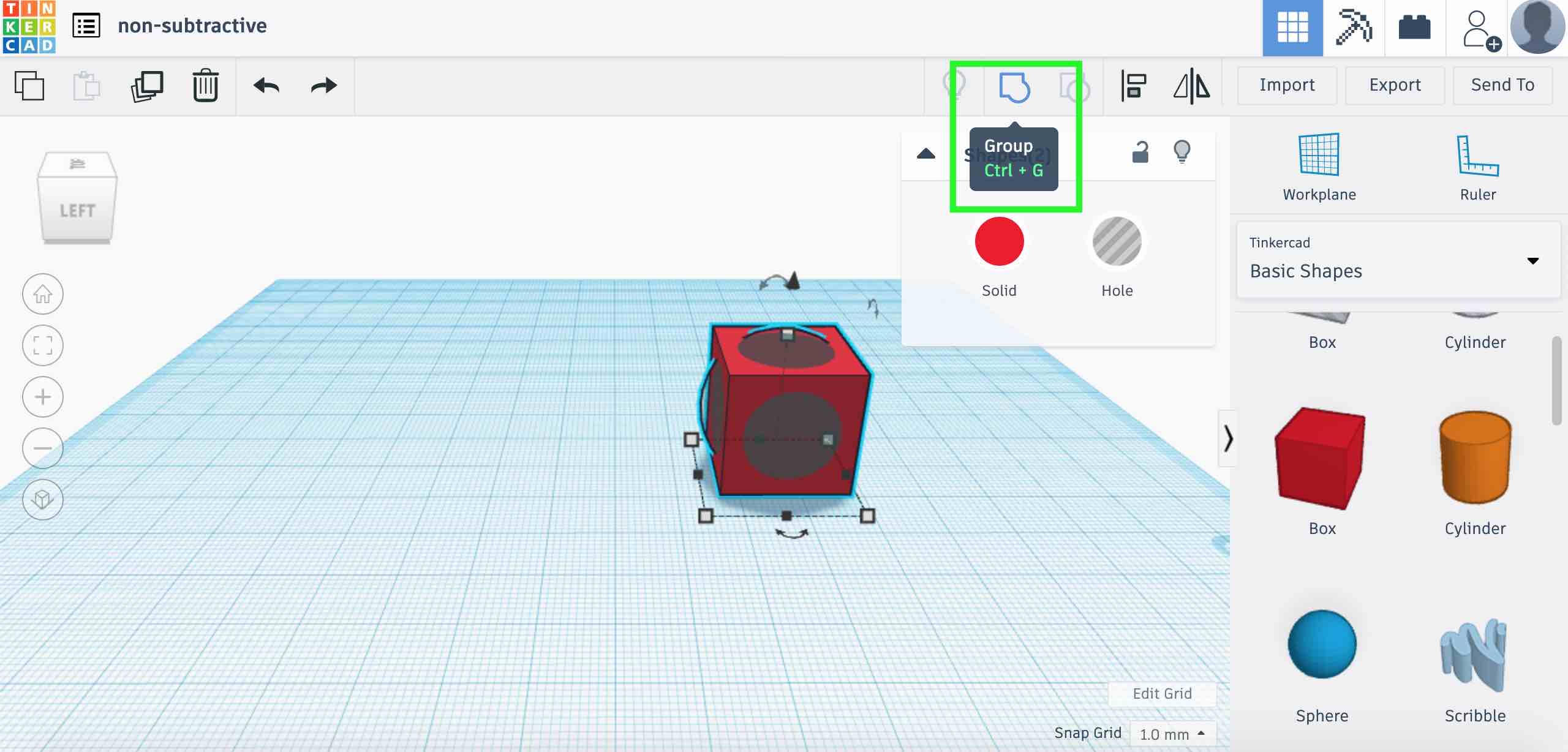

Group both Sphere and Cube after selecting them.

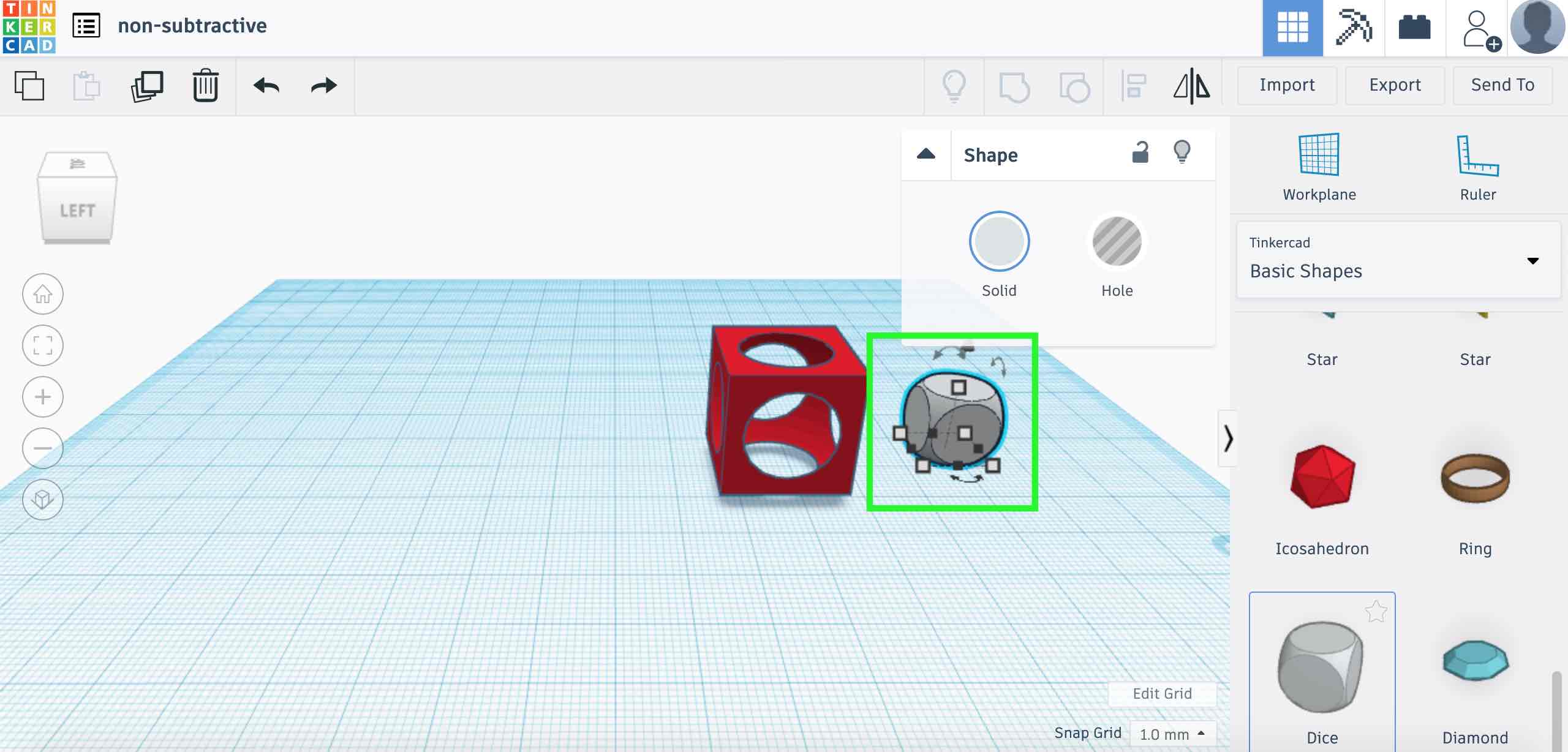

Add a Dice with the desired size.

Align the Sphere with the Object after selecting them.

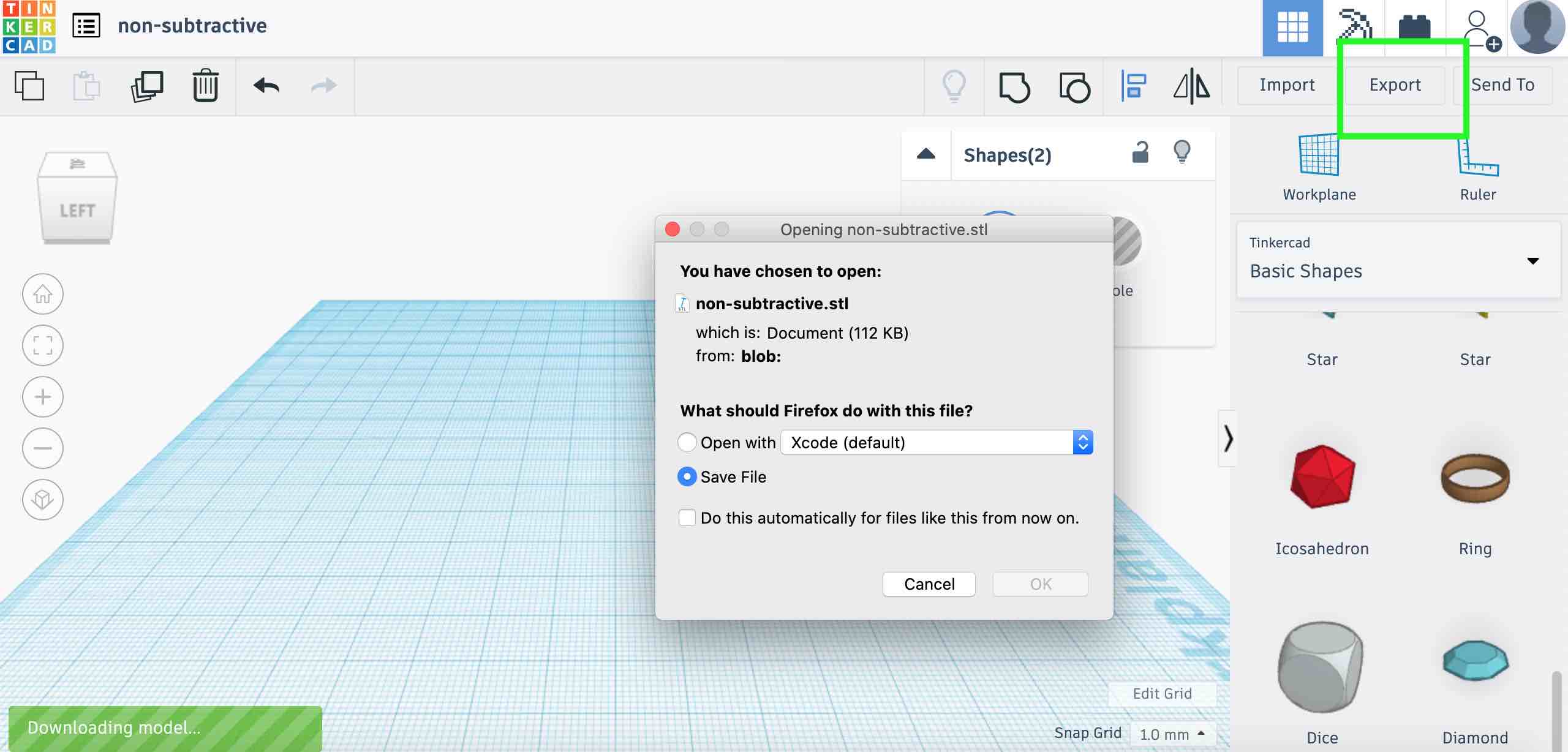

Export the .STL!

Note

The Object cannot be produced subtractively only due to the fact that it is an object with an object e.g., a milling bit would not be able to access certain parts of the design.

A personal 3D printer was used. RoboxDual includes a Dual Material Head, 2 extruders and the ability to print in 2 materials at once. AutoMaker is a Software provided by RoboxDual for sending files to the printer.

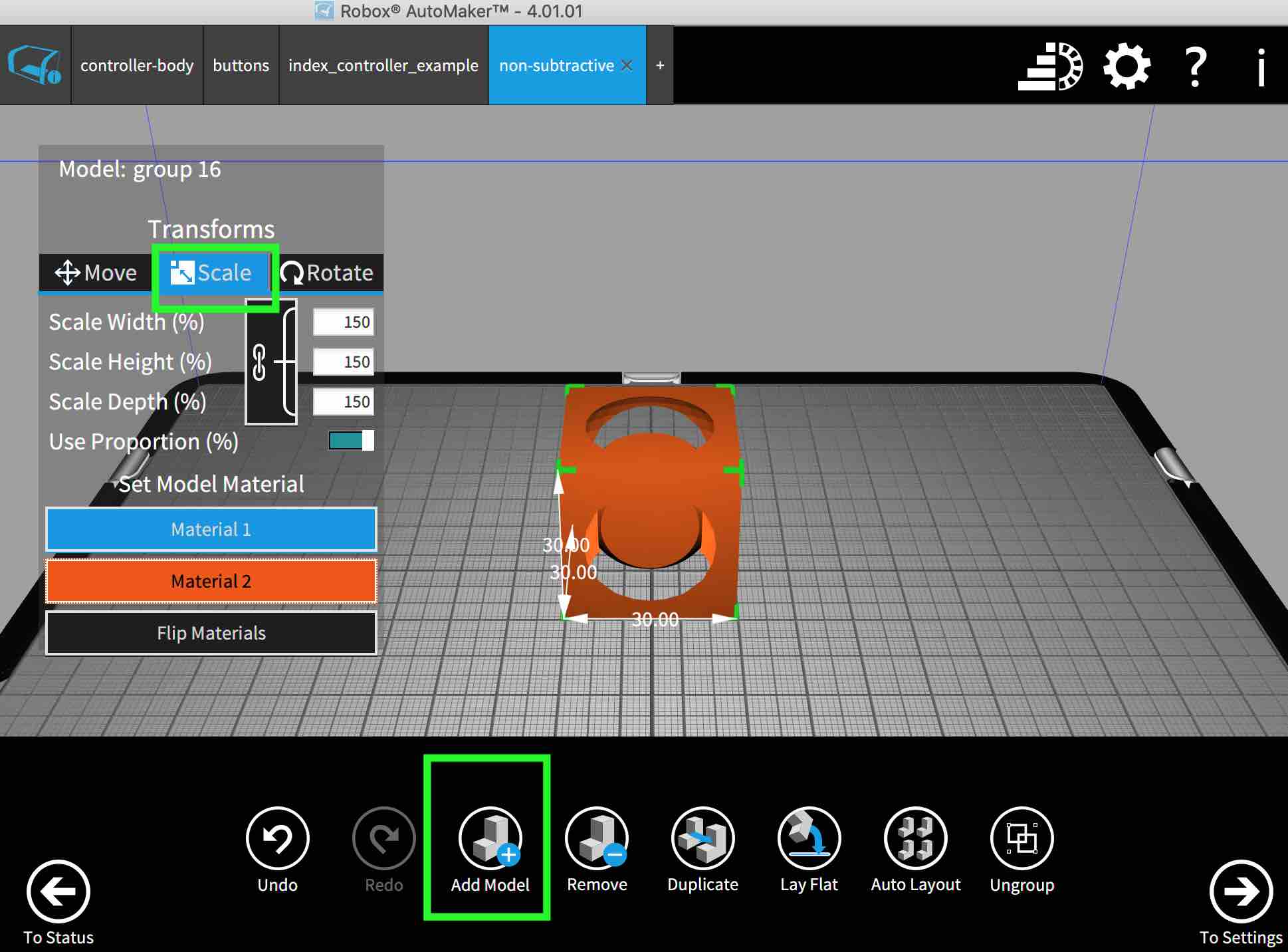

The model was imported. Then, it was resized.

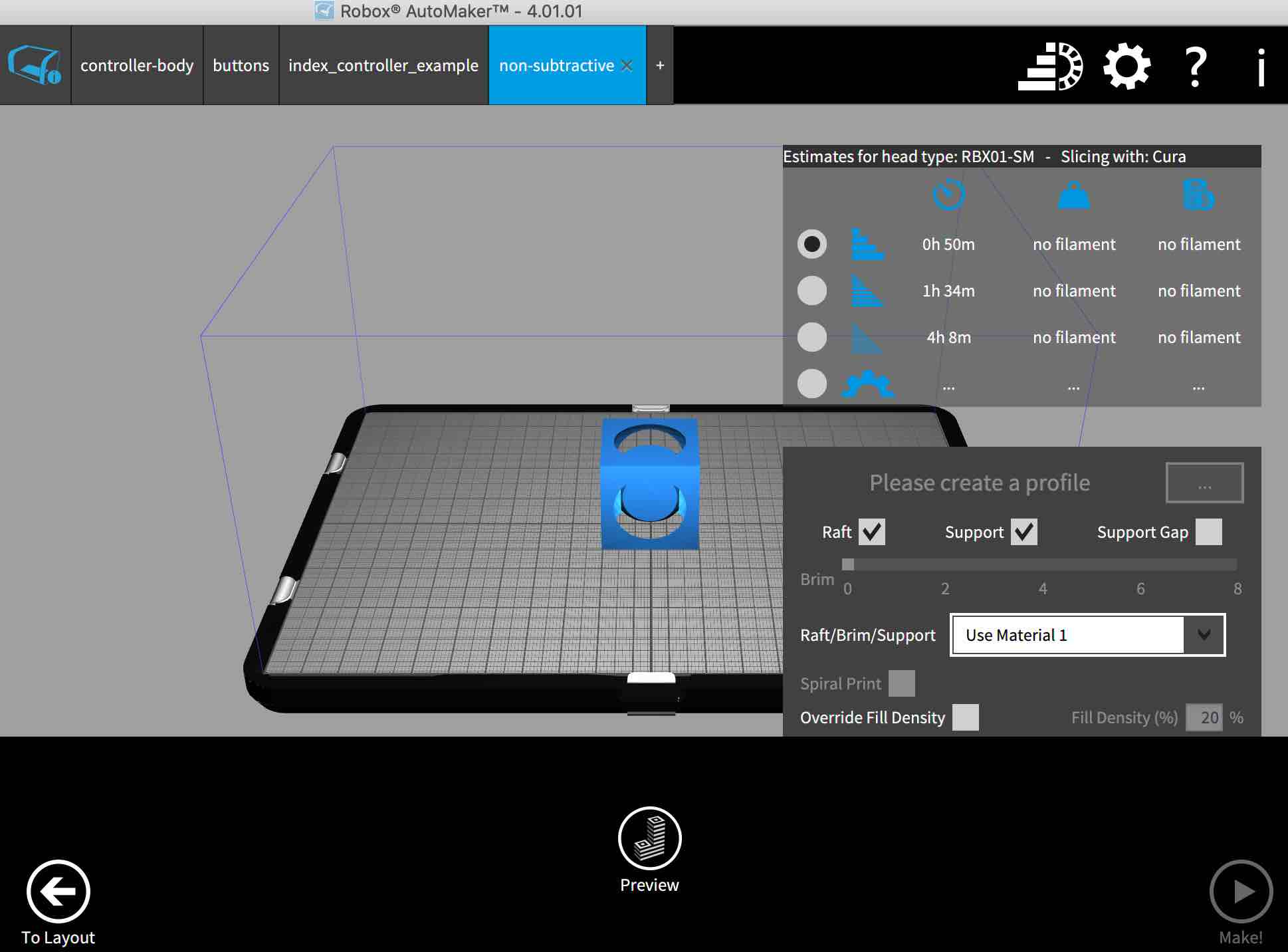

The 3D model was printed with support and raft. The following image shows print settings.

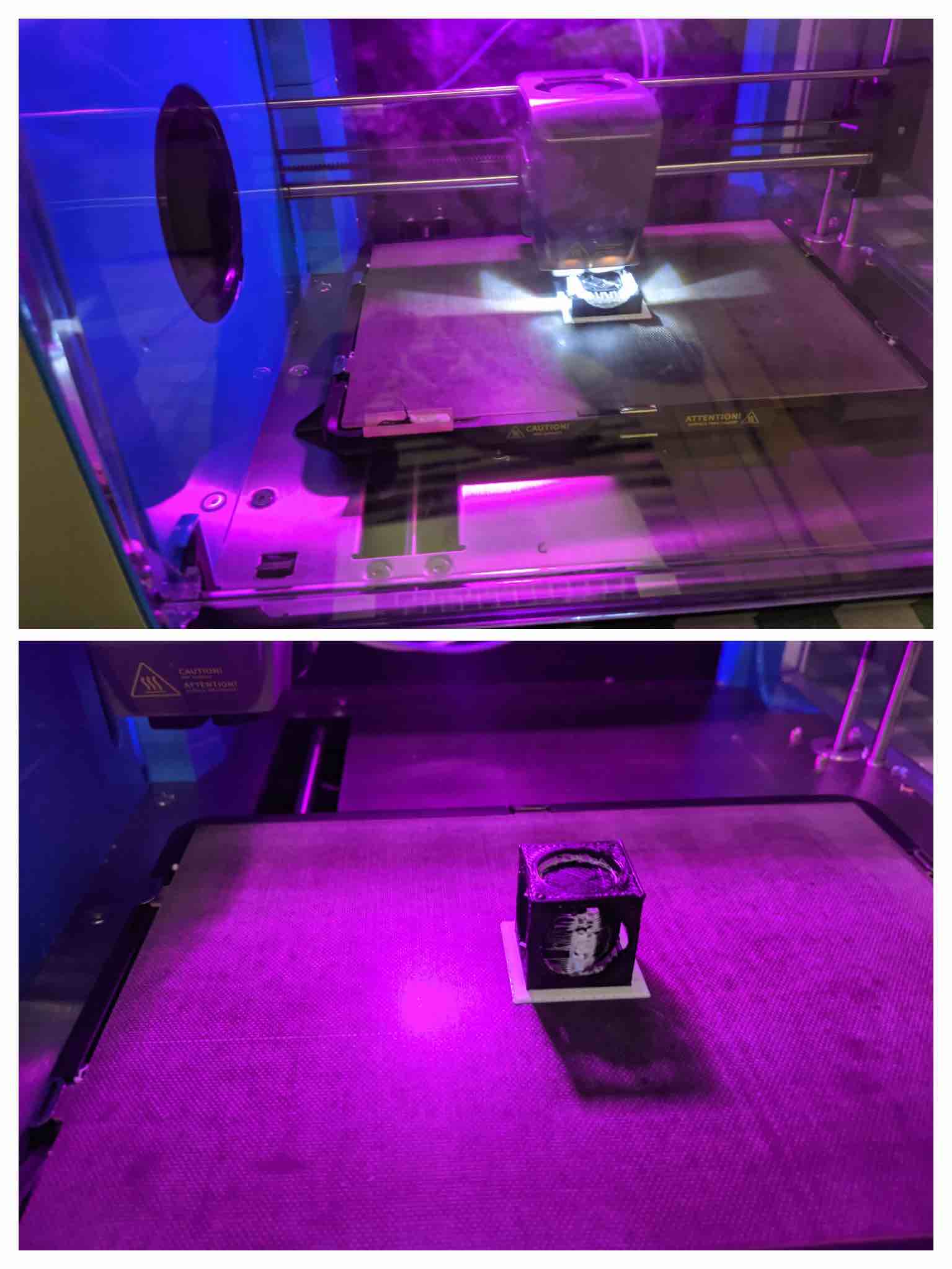

Printing Process …

The Final 3D printed model. Support was cleaned!

Note

The rationale of the design is experimenting/constructing a dice that can function in an enclosed space … can be developed farther for board games (no need to throw a dice across the table anymore!).

3D Scanning¶

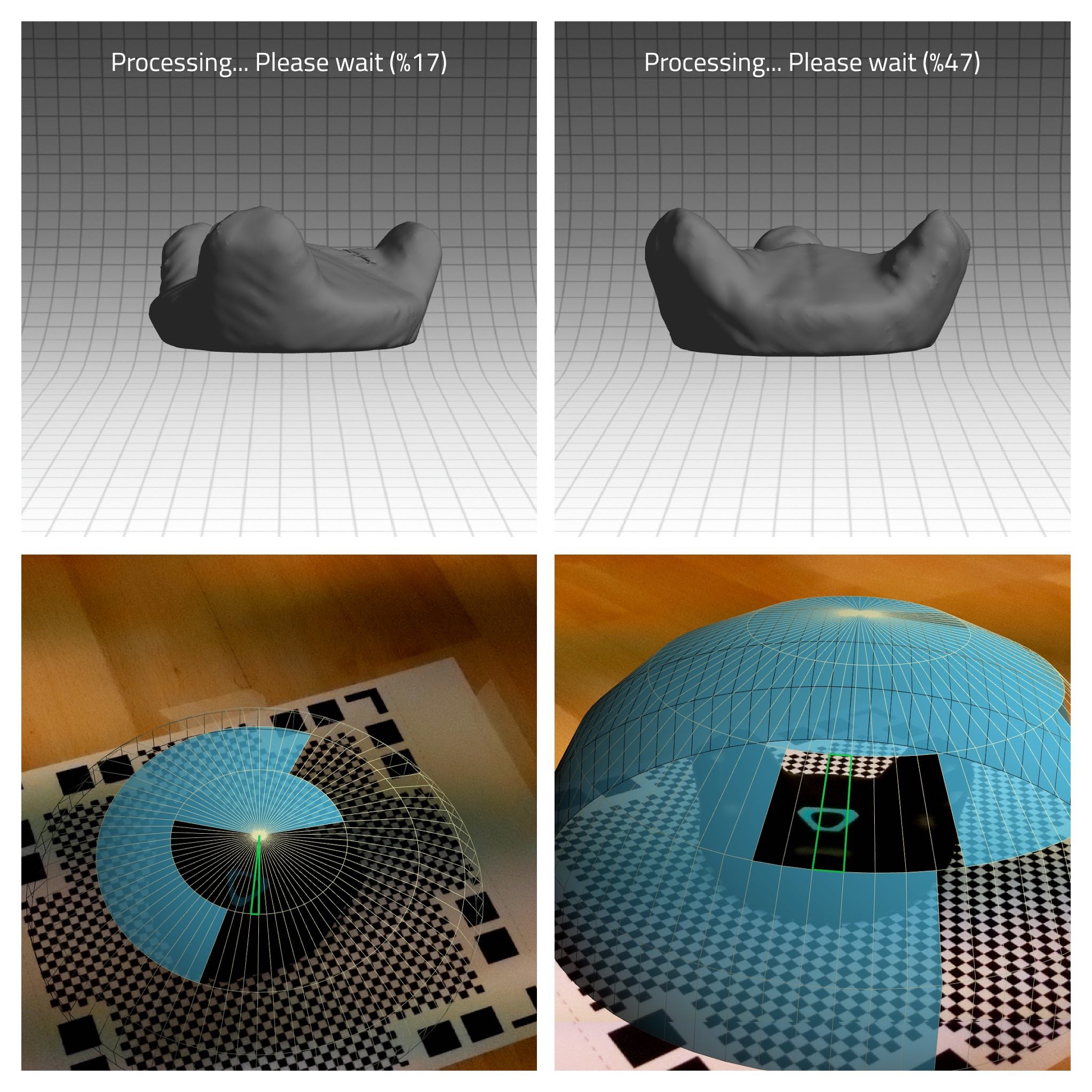

Qlone was used to scan an Object; The VIVE Tracker. The object was placed at the center. Light and surroundings were taken into consideration when scanning. Additionally, a mat has to be printed to guide the software.

Software Interface and Scanning¶

The process is straight forward. The object was placed at the of the mat and the phone is then rotated while keeping the object in view (see the blue half a Sphere).

Scanning Result

Reflection¶

Designing and Printing a non-Subtractive object was straight forward. Although I had to wrap my head around what non-Subtractive exactly means … So I had to redo this assignment.

3D scanning is painful; the object has to be placed in the center the whole time while moving the hand slowly. The quality is not that great either. I probably should have tried another method.

Files¶

Group Work¶

For the Group Work, we needed to test the design rules for different 3D printers. The main reason for testing the design rules for different 3D printers is that these printers have different capabilities. They may use different materials, adopt different algorithms, and have different strategies in dealing with complex structures. Thus, it is necessary to acquire this knowledge in order to choose the most appropriate 3D printers for work.

Stratasys Fortus 380mc, Sindoh 3DWOX DP200 and MakerBot Replicator 2 were all compared. See:

https://fabacademy.org/2020/labs/oulu/students/noora-nyberg/assignments/week06/